Preparation method of low-triphenyl phosphate engineering plastic halogen-free flame retardant

A technology of low triphenyl phosphate and engineering plastics, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of high toxicity of triphenyl phosphate and easy darkening of product color and other problems, to achieve the effect of meeting industrial scale production, easy operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

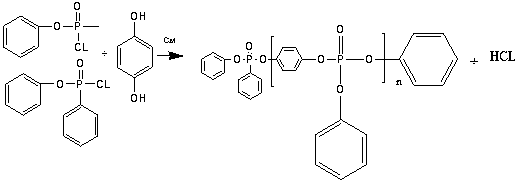

Method used

Image

Examples

Embodiment 1

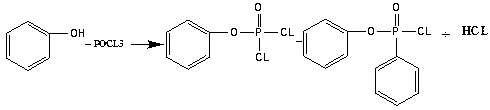

[0024] Add 78g (0.5mol) of phosphorus oxychloride and 0.1g of magnesium chloride to a four-necked flask and raise the temperature to 70-80°C, then slowly add 50g (0.55mol) of phenol dropwise for 2.5 hours. Afterwards, keep the reaction at 80-90°C for 5 hours until no hydrogen chloride is released, and the reaction is completed. After the reaction, distill phosphorus oxychloride under reduced pressure with a vacuum degree of 30-100KPa and a distillation temperature of 30-100°C. After reduced pressure distillation, the mixture is obtained Intermediate, i.e. a monosubstituted and disubstituted mixture of phosphorus oxychloride, the ratio of monosubstituted and disubstituted mixture is 4:6, the yield of the mixture intermediate is 95%, and the recovery rate of phosphorus oxychloride is 95% ( Calculated as phosphorus oxychloride);

[0025] Put the mixture intermediate into a four-necked flask, add 0.1g of magnesium chloride, first add 60g of hydroquinone, slowly raise the temperatu...

Embodiment 2

[0030]Add 160g (1mol) of phosphorus oxychloride and 1g of titanium tetrachloride into a four-necked flask for reaction, raise the temperature to 70-80°C, and slowly add 94g (1mol) of phenol dropwise. The time for adding phenol is about 2- 3 hours, after the dropwise addition, keep warm at 80-90°C for 3-5 hours, until no hydrogen chloride is released, the reaction is complete, after the reaction, distill phosphorus oxychloride under reduced pressure, the vacuum degree is 30-100KPa, and the distillation temperature is 30- At 100°C, the mixture intermediate was obtained after vacuum distillation, a mixture of monosubstituted and disubstituted phosphorus oxychloride, the ratio of the mixture was 5:5, gas phase analysis, the mixture intermediate was obtained, the yield of the intermediate was 95%, three The recovery rate of phosphorus oxychloride is 95% (calculated as phosphorus oxychloride);

[0031] Put the mixture intermediate into a four-necked flask, add 1g of titanium tetrach...

Embodiment 3

[0036] Add 1600g (1mol) of phosphorus oxychloride and 10g of aluminum trichloride into a four-necked flask for reaction, raise the temperature to 70-80°C, slowly add 1120g (1.1mol) of phenol dropwise, and the time for adding phenol is about 2 -3 hours, after the dropwise addition, keep the temperature at 80-90°C for 3-5 hours, until no hydrogen chloride is released, the reaction is complete, after the reaction, the vacuum degree of the phosphorus oxychloride distillation tower is 30-100KPa, and the distillation temperature is 30 -100°C, the mixture intermediate was obtained after vacuum distillation, a mixture of monosubstituted and disubstituted phosphorus oxychloride, the ratio of the mixture was 4:6, gas phase analysis, the mixture intermediate was obtained, and the yield of the intermediate was 95%, The recovery rate of phosphorus oxychloride is 95% (calculated as phosphorus oxychloride).

[0037] Put the mixture intermediate into a four-necked flask, add 10g of aluminum t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com