Fireproof coating for thermal insulation walls

A technology for fire-resistant coatings and heat-insulating walls, applied in the direction of fire-resistant coatings, etc., can solve the problems of reduced coating performance, loss of personnel and property, weak effect, etc., and achieve the effects of improving thermal insulation performance, increasing coating fullness, and strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

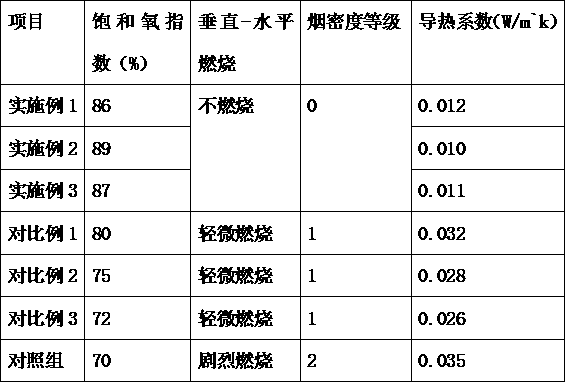

Examples

Embodiment 1

[0014] A fireproof coating for thermal insulation walls, which is made of the following components in parts by weight: 30 parts of polyvinyl acetate emulsion, 20 parts of polyvinyl alcohol, 18 parts of ammonium polyphosphate, 16 parts of pentaerythritol, 14 parts of melamine resin, hexamethylene 8 parts of tetramine, 4 parts of chlorinated paraffin, 3 parts of surfactant, 1.3 parts of glass powder, 0.8 part of asbestos powder, 0.3 part of ultrafine dispersed nano-alumina powder, 0.1 part of nano-silica, 35 parts of water, The nano-alumina powder is prepared by a sol-gel method, and the preparation method comprises the following steps:

[0015] (1) Use aluminum ethoxide as the raw material, add 5 times the volume of dodecane to mix and make a solution, slowly add distilled water dropwise under heating in a water bath at 80°C, the amount of distilled water is 25% of the mass of the reaction system, and polymerize at 75°C Form a sol, and leave it to stand for 10 hours after fully...

Embodiment 2

[0021] A fireproof coating for thermal insulation walls, made of the following components in parts by weight: 32 parts of polyvinyl acetate emulsion, 22 parts of polyvinyl alcohol, 20 parts of ammonium polyphosphate, 18 parts of pentaerythritol, 16 parts of melamine resin, hexamethylene 10 parts of tetramine, 5 parts of chlorinated paraffin, 4 parts of surfactant, 1.4 parts of glass powder, 0.9 part of asbestos powder, 0.4 part of ultrafine dispersed nano-alumina powder, 0.2 part of nano-silica, 38 parts of water, The nano-alumina powder is prepared by a sol-gel method, and the preparation method comprises the following steps:

[0022] (1) Use aluminum ethoxide as the raw material, add 6 times the volume of dodecane and mix it into a solution, slowly add distilled water dropwise under heating in a water bath at 85°C, the amount of distilled water is 25% of the mass of the reaction system, and polymerize at 75°C Form a sol, and leave it to stand for 11 hours after stirring full...

Embodiment 3

[0028] A fireproof coating for thermal insulation walls, which is made of the following components in parts by weight: 35 parts of polyvinyl acetate emulsion, 25 parts of polyvinyl alcohol, 22 parts of ammonium polyphosphate, 20 parts of pentaerythritol, 18 parts of melamine resin, hexamethylene 12 parts of tetramine, 6 parts of chlorinated paraffin, 5 parts of surfactant, 1.5 parts of glass powder, 1.0 part of asbestos powder, 0.5 part of ultrafine dispersed nano-alumina powder, 0.3 part of nano-silica, 40 parts of water, The nano-alumina powder is prepared by a sol-gel method, and the preparation method comprises the following steps:

[0029] (1) Use aluminum ethoxide as the raw material, add 8 times the volume of dodecane to mix and make a solution, slowly add distilled water dropwise under heating in a 90°C water bath, the amount of distilled water is 30% of the mass of the reaction system, and polymerize at 80°C Form a sol, and leave it to stand for 12 hours after stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com