Biocatalytic oxidation

A technology of microorganisms and species, applied in the field of biocatalytic oxidation, can solve the problem of expensive oxidation of organic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Oxidation of butanol to butyrate using E. coli and glucose as a co-substrate

[0114] For the bioconversion of butanol to butyrate, the plasmid-carrying strain E. coli W3110 ∆fadE pBT10 was used. The plasmid pBT10 is described in WO2009 / 077461, and the E. coli strain is described in WO2013 / 092547.

[0115] The recombinant E. coli W3110 ∆fadE pBT10 was cultured on plate count agar (Merck, Germany) with 50 mg / l kanamycin.

[0116] For the first pre-culture, in a 250 mL shake flask, 25 mL of LB medium (Merck, Germany) with 50 mg / L kanamycin was inoculated with a single colony from a freshly incubated agar plate and incubated at 37°C Incubate at 200 rpm for 16 hours. For the second pre-culture, 100 mL of HZD medium (1.8 g / L (NH) with 50 mg / L kanamycin in a 1000 mL shake flask 4 ) 2 SO 4 , 19.1 g / L K 2 HPO 4 , 12.5 g / L KH 2 PO 4 , 6.7 g / L yeast extract, 2.3 g / L sodium citrate (Na 3 -Citrat) *2H 2 O, 170 mg / L NH 4 Fe-citrate (NH 4 Fe-Citrat), 5 mL / L trace element US3 (80mL / L 37% ...

Embodiment 2

[0122] Oxidation of butanol to butyric acid using E. coli and acetic acid as a co-substrate

[0123] For the bioconversion of butanol to butyrate, the plasmid-carrying strain E. coli W3110 ∆fadE pBT10 was used. The plasmid pBT10 is described in WO2009 / 077461, and the E. coli strain is described in WO2013 / 092547.

[0124] The recombinant E. coli W3110 ∆fadE pBT10 was cultured on plate count agar (Merck, Germany) with 50 mg / l kanamycin.

[0125] For the first pre-culture, in a 250 mL shake flask, 25 mL of LB medium (Merck, Germany) with 50 mg / L kanamycin was inoculated with a single colony from a freshly incubated agar plate and incubated at 37°C Incubate at 200 rpm for 16 hours. For the second pre-culture, 100 mL of HZD medium (1.8 g / L (NH) with 50 mg / L kanamycin in a 1000 mL shake flask 4 ) 2 SO 4 , 19.1 g / L K 2 HPO 4 , 12.5 g / L KH 2 PO 4 , 6.7 g / L yeast extract, 2.3 g / L sodium citrate*2H 2 O, 170 mg / L NH 4 Fe-citrate, 5 mL / L trace element US3 (80 mL / L 37% HCl, 1.9 g / L MnCl 2 *4H ...

Embodiment 3

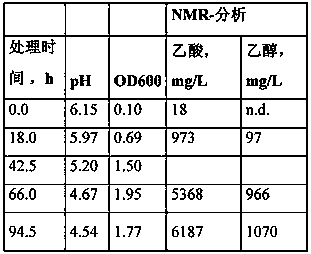

[0131] Production of acetic acid and ethanol from syngas by Clostridium ljungdahlii in the absence of oxygen

[0132] In the present example, Clostridium ljungdahlii has the H 2 And CO 2 The composition of the synthesis gas is cultured anaerobic in a complex medium to produce acetic acid and ethanol. For the cell culture of Clostridium ljungdahlii, 2 mL of cryoculture (Cryoculture) was anaerobicly cultured with approximately 400 mg / L L-cysteine hydrochloride and 400 mg / L Na 2 S×9H 2 200 ml medium of O (ATCC1754 medium: pH 6.0; 20 g / L MES; 1 g / L yeast extract, 0.8 g / L NaCl, 1g / L NH 4 Cl, 0.1 g / L KCl, 0.1 g / L KH 2 PO 4 , 0.2 g / L MgSO 4 ×7H 2 O; 0.02 g / L CaCl 2 ×2H 2 O; 20 mg / L nitrilotriacetic acid 10 mg / L MnSO 4 ×H 2 O; 8 mg / L (NH 4 ) 2 Fe(SO 4 ) 2 ×6H 2 O; 2 mg / L CoCl 2 ×6H 2 O; 2 mg / L ZnSO 4 ×7H 2 O; 0.2 mg / L CuCl 2 ×2H 2 O; 0.2 mg / L Na 2 MoO 4 ×2H 2 O; 0.2 mg / LNiCl 2 ×6H 2 O; 0.2 mg / / L Na 2 SeO 4 ; 0.2 mg / L Na 2 WO 4 ×2H 2 O; 20μg / L d-biotin, 20μg / L folic acid, 100 g / L pyridox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com