Preparation method of graphene/nickel bicarbonate nanometer cubic three-dimensional composite material and application of composite material to energy storage

A nano-cube, nickel bicarbonate technology, applied in the direction of graphene, nickel carbonate, nano-carbon, etc., can solve the problems affecting the cycle performance of electrode materials, product performance and application impact, and uneven product structure and morphology, so as to facilitate industrial The effect of mass production, excellent electrochemical performance, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of graphene / nickel bicarbonate nano cube three-dimensional composite material, comprises the following steps:

[0033] The first step, graphene oxide hydrosol preparation

[0034] Graphene oxide was prepared by the optimized and improved Hummer's method, and the obtained graphene oxide was ultrasonically dispersed in water to obtain a graphene oxide hydrosol; the graphene oxide hydrosol prepared in this step included 0.5~2.0 g / L graphite oxide Graphene oxide has a negative charge on its surface because it contains a large number of hydroxyl groups, carboxyl groups, carbonyl groups, epoxy groups and other oxygen-containing groups on the surface, so it is easier to fix metal oxides than reduced graphene oxide for the preparation of metal oxides. Oxide / graphene composites;

[0035] The second step, graphene / nickel bicarbonate airgel preparation

[0036] Add urea to the graphene oxide hydrosol prepared in the first step,...

Embodiment 1

[0054] The preparation method of the graphene / nickel bicarbonate nanocube three-dimensional composite material of the present embodiment comprises:

[0055] (1) Preparation of graphene oxide hydrosol

[0056] The obtained graphene oxide is ultrasonically dispersed in water to obtain a 1.0 g / L graphene oxide hydrosol;

[0057] (2) Preparation of graphene / nickel bicarbonate airgel

[0058] Add urea to the graphene oxide hydrosol prepared in step (1), stir for 8 minutes, then slowly add nickel acetate, and stir for 8 minutes to obtain a precursor solution, which contains 1.0g / L graphene oxide, 0.2mol / L urea, 0.02 mol / L nickel acetate;

[0059] Transfer the precursor solution into the reactor, and place the reactor in an oven at 180°C for 24 hours to obtain graphene / nickel bicarbonate airgel;

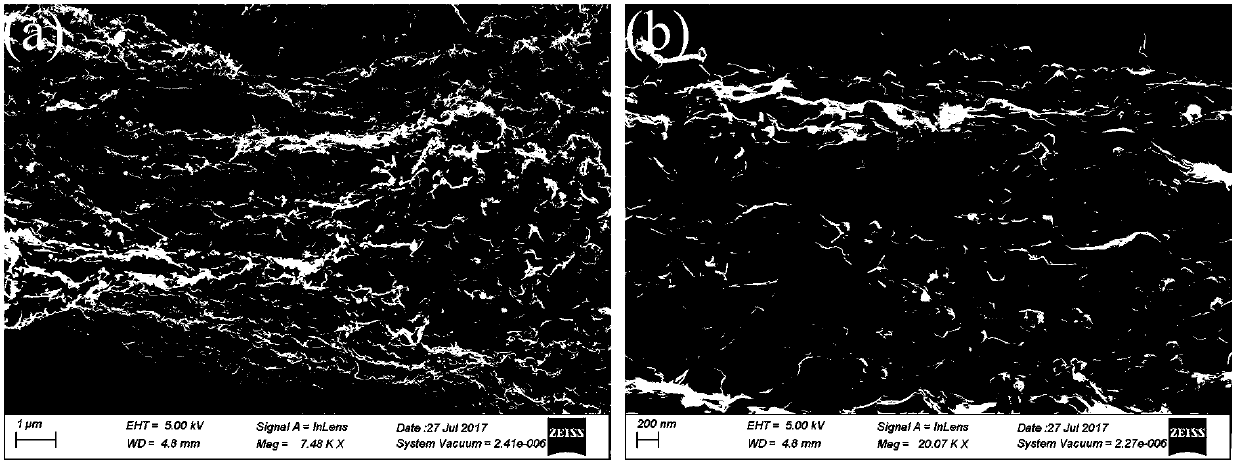

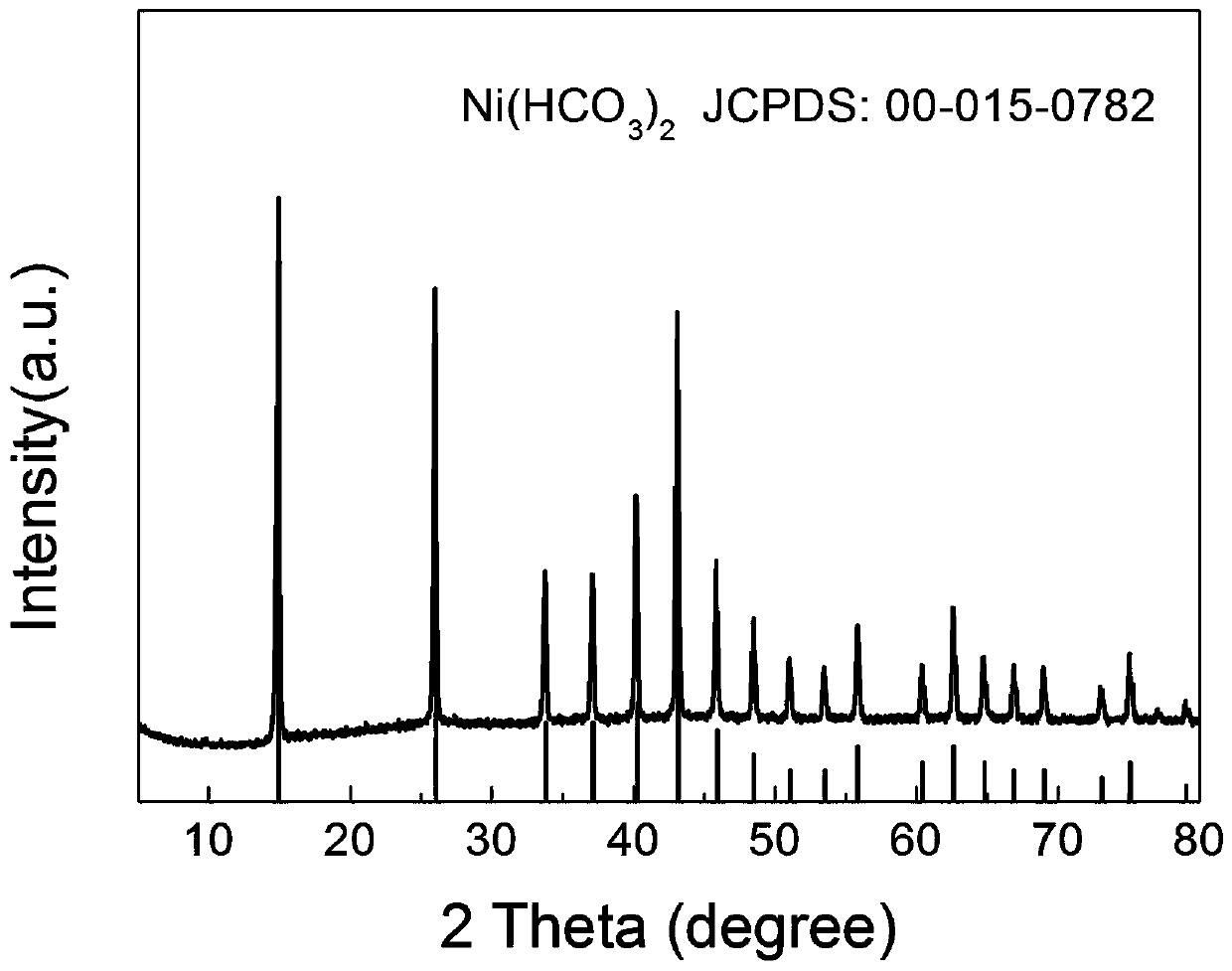

[0060] (3) Preparation of graphene / nickel bicarbonate composites

[0061] The graphene / nickel bicarbonate aerogel prepared in step (2) was washed with pure water to remove soluble impur...

Embodiment 2

[0064] The preparation method of the graphene / nickel bicarbonate nanocube three-dimensional composite material of the present embodiment comprises:

[0065] (1) Preparation of graphene oxide hydrosol

[0066] The obtained graphene oxide is ultrasonically dispersed in water to obtain a 1.5g / L graphene oxide hydrosol;

[0067] (2) Preparation of graphene / nickel bicarbonate airgel

[0068] Add urea to the graphene oxide hydrosol prepared in step (1), stir for 10 minutes, then slowly add nickel acetate, and stir for 10 minutes to obtain a precursor solution, which contains 1.5g / L graphene oxide, 0.4mol / L urea, 0.04 mol / L nickel acetate;

[0069] Transfer the precursor solution into the reactor, and place the reactor in an oven at 180°C for 24 hours to obtain graphene / nickel bicarbonate airgel;

[0070] (3) Preparation of graphene / nickel bicarbonate composites

[0071] The graphene / nickel bicarbonate aerogel prepared in step (2) was washed with pure water to remove soluble impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com