Nanocrystal ordered mesopore TiO2 film and preparation method thereof

A nanocrystalline and ordered mesoporous technology is applied in the field of nanocrystalline ordered mesoporous TiO2 film and its preparation, and achieves the effects of high thermal stability, good degradation performance, and high order degree of pore arrangement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

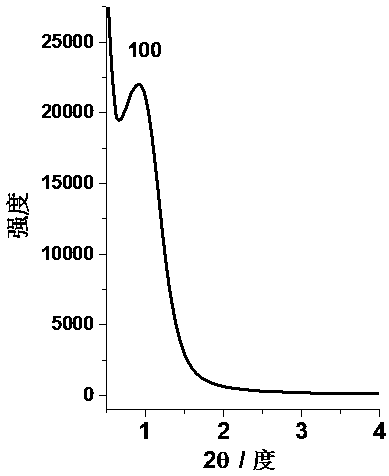

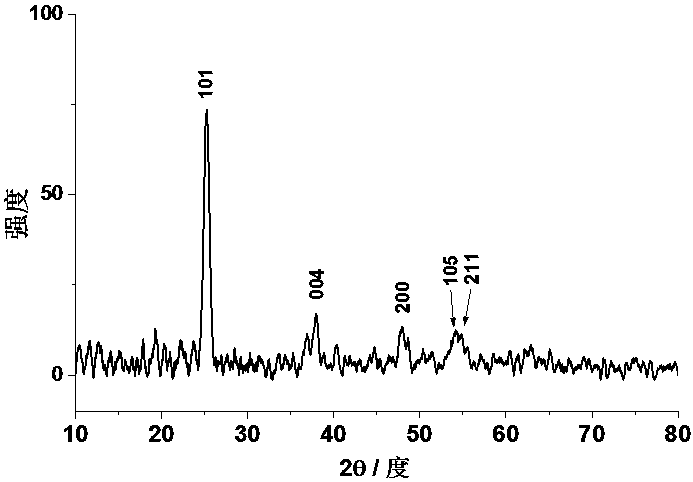

[0035] Example 1, high thermal stability, ordered mesoporous TiO with two-dimensional hexagonal structure 2 Membrane synthesis: Dissolve 2 g of P123 template in 20 – 60 g of ethanol and stir for 3 – 5 hours. Add 0.02 mol of ethyl titanate or isopropyl titanate or butyl titanate or titanium tetrachloride, and 0.02-8 g of one of the above-mentioned acids, and continue stirring for 3-5 hours. Transfer the sol solution to a cabinet with a temperature of 10-20°C, a relative humidity of 10-20%, and filled with saturated ethanol vapor. A layer of sol liquid film is covered on the surface of glass sheet, ceramic sheet, single crystal silicon sheet and stainless steel sheet by immersion-pulling method, and then the substrate with liquid film is placed horizontally on the sample holder. Regulating the outward diffusion flow of ethanol vapor in the cabinet, the ethanol on the surface of the carrier is gradually volatilized, and the titanium source molecules and their oligomers and the t...

Embodiment 2

[0036] Example 2, high thermal stability, three-dimensional hexagonal structure ordered mesoporous TiO 2 Synthesis of membrane material: Dissolve 1 gram of F127 template in 20 – 40 grams of ethanol and stir for 8 – 10 hours. Add 0.015 mol of ethyl titanate or isopropyl titanate or butyl titanate or titanium tetrachloride, and 0.02 - 8 g of one of the above acids, and continue stirring for 8 - 10 hours. Transfer the sol solution to a cabinet filled with saturated ethanol vapor at a temperature of 20-30°C and a relative humidity of 40-50%. A layer of sol liquid film is covered on the surface of glass sheet, ceramic sheet, single crystal silicon sheet and stainless steel sheet by immersion-pulling method, and then the substrate with liquid film is placed horizontally on the sample holder. Regulating the outward diffusion flow of ethanol vapor in the cabinet, the ethanol on the surface of the carrier is gradually volatilized, and the titanium source molecules and their oligomers ...

Embodiment 3

[0037] Example 3, synthesis of highly thermally stable and ordered mesoporous titanium dioxide film with three-dimensional cubic structure: 1.5 grams of F108 template agent was dissolved in 40-50 grams of ethanol, and stirred for 6-8 hours. Add 0.03 mol of ethyl titanate or isopropyl titanate or butyl titanate or titanium tetrachloride, and 0.02 - 8 g of one of the above acids, and continue stirring for 10 - 12 hours. Transfer the sol solution to a cabinet filled with saturated ethanol vapor at a temperature of 35-45°C and a relative humidity of 70-80%. A layer of sol liquid film is covered on the surface of glass sheet, ceramic sheet, single crystal silicon sheet and stainless steel sheet respectively by dipping-pulling method, and then the substrate carrying the liquid film is placed on the sample holder. Regulating the flow of ethanol vapor in the cabinet to diffuse outward, the ethanol on the surface of the substrate is gradually volatilized, and the titanium source molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com