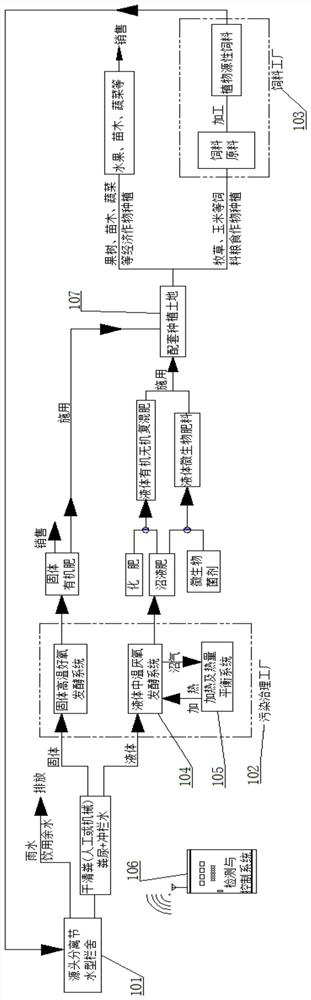

A system and method for ecological treatment of livestock and poultry manure liquid

A pollution control and liquid technology, applied in the field of manure liquid ecological management system of livestock and poultry farms, can solve problems such as liquid surface crusting, fermentation tank blockage, and safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for ecological treatment of pig farm manure liquid, comprising the steps of:

[0060] 1. Separation of the source of the barn and water saving: the rain and drinking water are separated, and the rain and drinking water are discharged to the ditch outside the barn instead of being mixed into the feces and urine. Water-saving flushing of the barn, mechanical scraping of manure or manual dry cleaning Manure, at the source of the barn, rainwater and drinking water will not be mixed into the manure and urine, so as to minimize the amount of manure and urine. Clean the barn with a high-pressure water gun or even high-pressure air, mechanically scrape the manure or manually dry the manure to clean it out The pig manure is subjected to high-temperature aerobic fermentation to produce solid organic fertilizer 403, and the pig manure and flushing water are transported to the regulating tank 201;

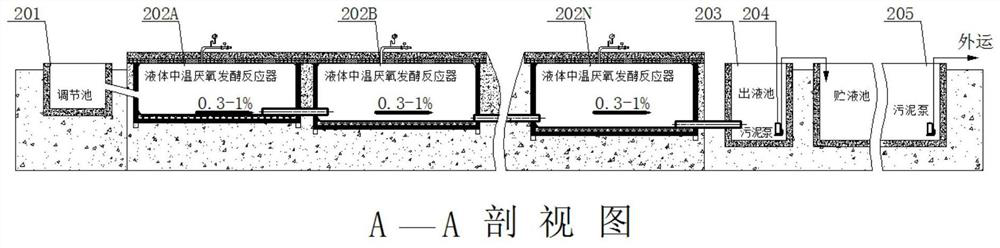

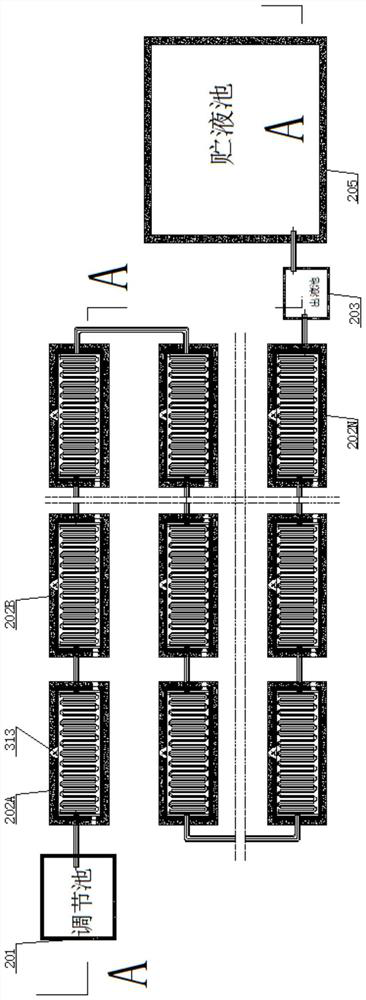

[0061] 2. Mesophilic anaerobic fermentation of manure liquid:

[0062] (1...

Embodiment 2

[0075] A method for ecological treatment of pig farm manure liquid, comprising:

[0076] 1. Separation of the source of the barn and water saving: the rain and drinking water are separated, and the rainwater and drinking water are discharged to the ditch outside the barn instead of being mixed into the excrement. At the source of the barn, rainwater and drinking water are not mixed into the feces and urine to minimize the amount of feces and urine. Cleaning the barn uses high-pressure water guns or even high-pressure air. 201;

[0077] 2. Mesophilic anaerobic fermentation of manure liquid:

[0078] (1) open solenoid valve 506d, tap water replenishes water to low-temperature heat preservation water tank 504 automatically, open solenoid valve 506f, low temperature heat preservation water tank 504 utilizes height difference under the control of detection control system 106, automatically replenishes water to high temperature heat preservation water tank 503, opens solenoid valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com