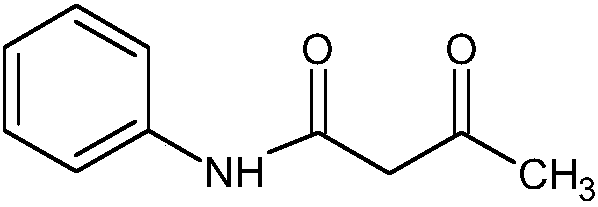

Preparation method of crystalline N-acetoacetanilide

A technology of acetoacetanilide and crystalline form, which is applied in the field of preparation of crystalline N-acetoacetanilide, to achieve the effects of reducing production energy consumption, uniform crystal shape, and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 3000L of 95% ethanol and 550kg (5.9kmol) of aniline into a 5000L condensation kettle, then add 556kg (6.49kmol) of diketene dropwise at <10°C, after the reaction is over, add 0.5kg of diketene to the condensation kettle Acetic acid, then heat up to 60°C, turn on the system vacuum, the vacuum degree starts from 760mmHg, gradually increases to 572mmHg, maintains at this vacuum degree for 30 minutes, then continues to increase the vacuum degree to 385mmHg, wait until the temperature drops below 40°C, then at 0.5 Continue to increase the vacuum degree to 100mmHg within an hour, finally reduce the vacuum degree to 10mmHg, and maintain it for 15 minutes. Stop the vacuum pump, ventilate the system, centrifuge, and dry to obtain 1035kg of N-acetoacetanilide finished product in the shape of quicksand with uniform crystallization. 99.93%, stacked for 120 days without caking.

Embodiment 2

[0047]Add 3000L of 40% ethanol and 550kg (5.9kmol) of aniline into a 5000L condensation kettle, then add 556kg (6.49kmol) of diketene dropwise at <10°C, after the reaction is over, add 0.2kg of diketene to the condensation kettle Sulfuric acid, then heat up to 70°C, turn on the system vacuum, the vacuum degree starts from 760mmHg, gradually increases to 460mmHg, maintains at this vacuum degree for 50 minutes, then continues to increase the vacuum degree to 310mmHg, wait until the temperature drops below 40°C, and then in 1 Continue to increase the vacuum degree to 85mmHg within an hour, finally reduce the vacuum degree to 8mmHg, and maintain it for 15 minutes. Stop the vacuum pump, ventilate the system, centrifuge, and dry to obtain 1037kg of N-acetylacetanilide finished product with uniform crystallization and the shape of quicksand. 99.92%, stacked for 120 days without caking.

Embodiment 3

[0049] Add 3000L of 95% methanol and 550kg (5.9kmol) of aniline into a 5000L condensation kettle, then add 556kg (6.49kmol) of diketene dropwise at <10°C, and after the reaction is over, add 0.8kg of diketene to the condensation kettle Propionic acid, then heat up to 55°C, turn on the system vacuum, the vacuum degree starts from 760mmHg, gradually increases to 610mmHg, maintains at this vacuum degree for 40 minutes, then continues to increase the vacuum degree to 385mmHg, wait until the temperature drops below 40°C, and then Continue to increase the vacuum degree to 122mmHg within 1.5 hours, finally reduce the vacuum degree to 10mmHg, maintain for 30 minutes, stop the vacuum pump, the system is ventilated, centrifuged, and dried to obtain 1033kg of N-acetylacetanilide finished product with uniform crystallization and quicksand shape. The content is 99.91%, and it will not agglomerate after 120 days of stacking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com