Oil-based drilling fluid blocking remover and preparation method thereof

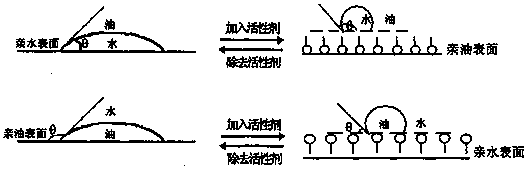

A technology of oil-based drilling fluid and plug-removing agent, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost and poor plug-removing effect, achieve low cost, strong drainage capacity, increase The effect of moisturizing contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0029] Experimental Example 1: Preferred Main Acid

[0030] Remove the inorganic matter in the oil-based mud, mainly clay (mainly montmorillonite). In the investigation of the acid solution system, under the conditions of the temperature of 60 ° C and the experimental time of 5 hours, the mass fraction of hydrochloric acid is 10%. , Composite acid (hydrochloric acid: hydrofluoric acid: nitric acid according to volume ratio 1:3:0.5), nitric acid, phosphoric acid to the mud dissolution rate is respectively 14.6%, 62.5%, 12.8% and 14.3%, wherein the compound acid to the mud dissolution effect most. Therefore, it is determined that the main acid for mud dissolution is compound acid.

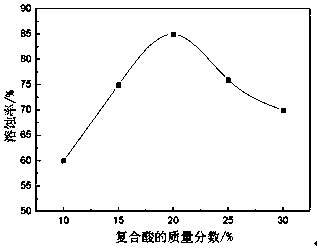

[0031] Under the conditions of the experimental temperature of 60°C and the experimental time of 5 hours, the results of the mud dissolution experiment of the compound acid with different preparation ratios are as follows: figure 1 shown. The experimental results show that with the increase of the...

experiment example 2

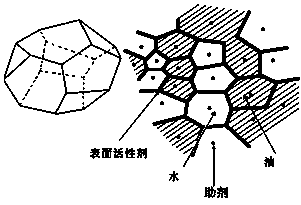

[0032] Experimental example 2: preferred emulsifier

[0033]Organic matter in oil-based mud, mainly white oil. Since the plugging removal system is water-based, an emulsifier must be used to remove the oily matter. Only by selecting a suitable emulsifier can the oily matter such as white oil be fully emulsified and discharged from the near wellbore area and wellbore. Experimental method: Mix oil and acid (add 6% emulsifier) in a certain ratio (30:20), stir evenly, and then measure the amount of demulsification at a certain temperature to determine its demulsification ability. The experimental results are shown in Table 1. It can be seen from Table 1 that the demulsification rate of the emulsifier alkylphenol ether sulfosuccinate sodium salt reaches 100% in 10 minutes, and the effect is the best. The emulsifier is preferably sodium salt of alkylphenol ether sulfosuccinate. The emulsifier is a trimeric phthaloamine structure. This organic amine surfactant can form a complex...

experiment example 3

[0040] Experimental example 3: Dispersant preferred

[0041] Since the oil-based mud is a mixture of oil, inorganic clay and various additives, a dispersant should be added to the plugging removal system to make the products after plugging removal form a relatively stable dispersion, which is not easy to re-agglomerate and can better carry out plugging removal. The residual liquid is completely discharged.

[0042] Experimental method: mix 0# diesel oil and acid liquid, add different kinds of dispersant respectively, the concentration of dispersant is 4%, measure the interfacial tension with JYW-200X interfacial tensiometer, the experimental data are shown in Table 3.

[0043] Table 3 Experimental data of dispersant screening

[0044] serial number

Dispersant

Average interfacial tension, mN / m

1

Sodium polyacrylate

1.8

2

Modified polycarboxylate

5.2

3

sodium polyepoxysuccinate

6.0

4

3.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com