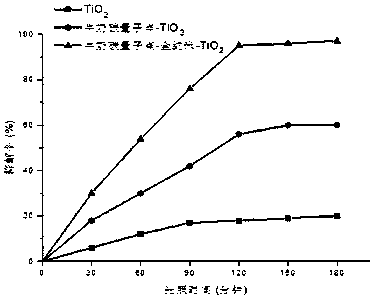

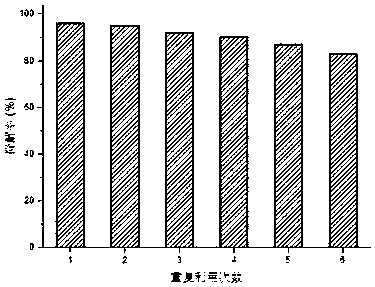

Preparation and application of titanium dioxide composite photocatalytic system

A composite photocatalysis and titanium dioxide technology, applied in the field of chemical industry, can solve problems such as difficult degradation, and achieve the effects of easy separation from liquid, short degradation time and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of carbon quantum dot solution: Weigh 80g of milk and add it to 20mL of ultrapure water, sonicate for 5min, transfer to a polytetrafluoroethylene reactor, heat at 180°C for 16h, cool naturally, and filter with a pore size of 0.22μm Membrane filtration, and then dialysis treatment with a dialysis bag with a molecular weight cut-off of 3000Da for 24 hours to obtain water-soluble carbon quantum dots.

[0023] 2. Preparation of composite photocatalytic system gold nano-carbon quantum dots-titanium dioxide, including the following steps:

[0024] (1) Preparation of gold nanoparticles: Mix 20 mg of chloroauric acid and 20 mg of polyvinylpyrrolidone and dilute to 50 mL, heat and stir the mixed solution, and inject 0.03 mol / L sodium borohydride solution rapidly after the temperature rises to 100 °C 15mL, continue to stir for 30min, remove the heat source, and naturally cool to room temperature to prepare a gold nanometer solution.

[0025] (2) Preparation of gol...

Embodiment 2

[0030] 1. Preparation of carbon quantum dot solution: Weigh 80g of milk and add it to 20mL ultrapure water, sonicate for 5min, transfer to a polytetrafluoroethylene reactor, heat at 200°C for 12h, cool naturally, and use a pore size of 0.22μm Membrane filtration, and then dialysis treatment with a dialysis bag with a molecular weight cut-off of 3500Da for 24 hours to obtain water-soluble carbon quantum dots. .

[0031] 2. Preparation of composite photocatalytic system gold nano-carbon quantum dots-titanium dioxide, including the following steps:

[0032] (1) Preparation of gold nanoparticles: Mix 20 mg of chloroauric acid and 20 mg of polyvinylpyrrolidone and dilute to 50 mL, heat and stir the mixed solution, and inject 0.03 mol / L sodium borohydride solution rapidly after the temperature rises to 100 °C 20mL, continue to stir for 30min, remove the heat source, and naturally cool to room temperature to prepare the AuNPs solution.

[0033] (2) Preparation of gold nano-carbon q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com