Rare earth elements co-doped indium sulfide material as well as preparation method and application thereof

A technology of rare earth elements and co-doping, which is applied in the fields of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems that the crystallinity of indium sulfide is easy to change, the shape and size of indium sulfide are difficult to control, and the sol Gel method has long synthesis period and other problems, to achieve the effect of improving photocatalytic performance, high photogenerated charge separation efficiency, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

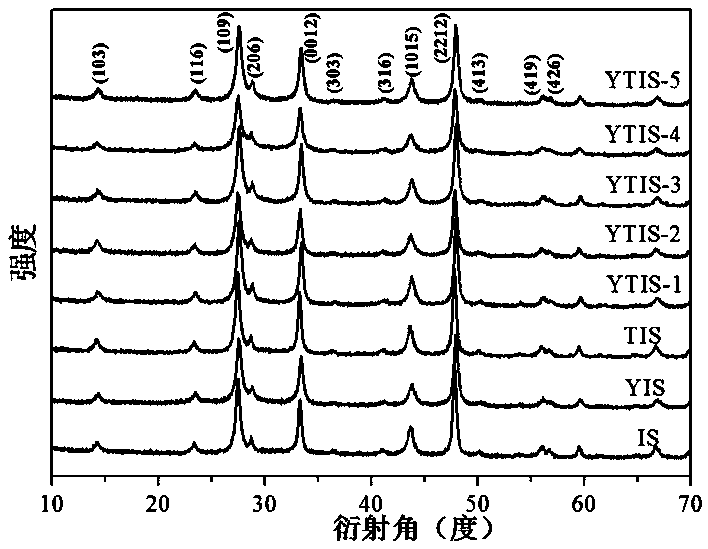

[0050] An indium sulfide material co-doped with rare earth elements is used to dope indium sulfide with rare earth elements Yb and Tm.

[0051] In this embodiment, the mass content of Yb in the indium sulfide material co-doped with rare earth elements is 7.3%, and the mass content of Tm is 0.71%.

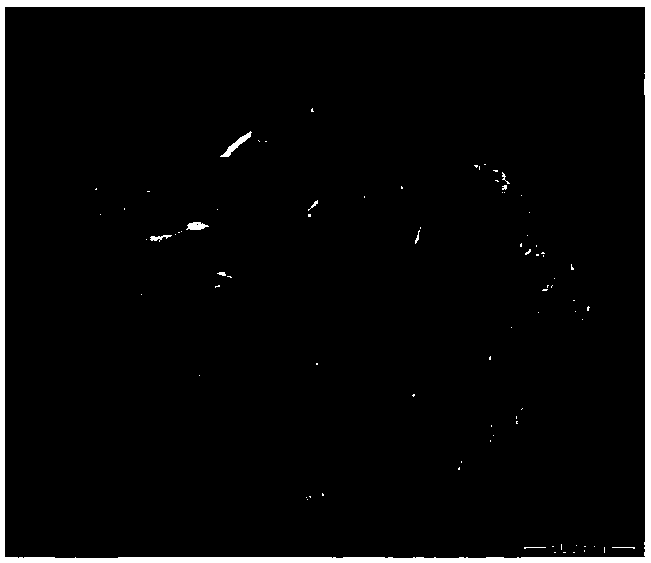

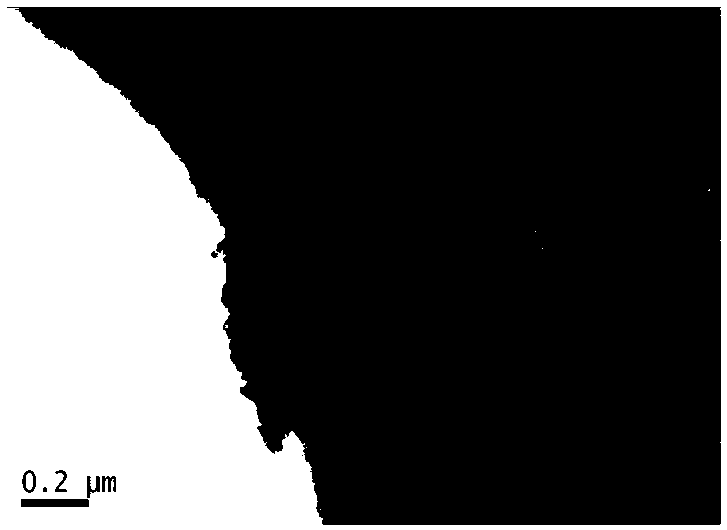

[0052] In this embodiment, the indium sulfide material co-doped with rare earth elements is flower-shaped microspheres, which are self-assembled by interweaving two-dimensional nanosheets, and have a three-dimensional network-like petal structure, wherein the flower-shaped microspheres The diameter is 200nm ~ 2000nm.

[0053] In this embodiment, the indium sulfide material co-doped with rare earth elements contains sulfur holes.

[0054] In this embodiment, the indium sulfide material co-doped with rare earth elements has a forbidden band width of 1.78 eV, and can up-convert near-infrared light into light of 270 nm to 800 nm.

[0055] A method for preparing the indium sulfide mate...

Embodiment 2

[0059] A rare earth element co-doped indium sulfide material, which is basically the same as the rare earth element co-doped indium sulfide material in Example 1, the difference is: (1) The rare earth element co-doped indium sulfide in Example 2 The mass content of Yb in the material is 14.3%, and the mass content of Tm is 0.69%. (2) The band gap of the indium sulfide material co-doped with rare earth elements in Example 2 is 1.79 eV.

[0060] A preparation method of the indium sulfide material co-doped with rare earth elements in the above-mentioned present embodiment is basically the same as the preparation method of the indium sulfide material co-doped with rare earth elements in Example 1, the difference is: the method of Example 2 In step (1) In 3 + , Yb 3+ and Tm 3+ The molar ratio is 179:20:1.

[0061] The rare earth element co-doped indium sulfide material (being Yb 3+ and Tm 3+ Co-doped In 2 S 3 ), labeled YTIS-2.

Embodiment 3

[0063] A rare earth element co-doped indium sulfide material, which is basically the same as the rare earth element co-doped indium sulfide material in Example 1, the difference is: (1) The rare earth element co-doped indium sulfide in Example 3 The mass content of Yb in the material is 20.9%, and the mass content of Tm is 0.68%. (2) The band gap of the indium sulfide material co-doped with rare earth elements in Example 2 is 1.79 eV.

[0064] A preparation method of the indium sulfide material co-doped with rare earth elements in the above-mentioned present embodiment is basically the same as the preparation method of the indium sulfide material co-doped with rare earth elements in Example 1, the difference is: the method of Example 3 In step (1) In 3 + , Yb 3+ and Tm 3+ The molar ratio is 169:30:1.

[0065] The rare earth element co-doped indium sulfide material (being Yb 3+ and Tm 3+ Co-doped In 2 S 3 ), labeled YTIS-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com