Mildewproof preservative film and preparation method thereof

A fresh-keeping film and anti-mildew technology, applied in coatings, starch derivative coatings, chitin polysaccharide coatings, etc., can solve the problems of insignificant anti-mildew effect, difficult recycling, loss of original value, etc., and achieve less pores. , The effect of preventing growth and reproduction and preventing mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

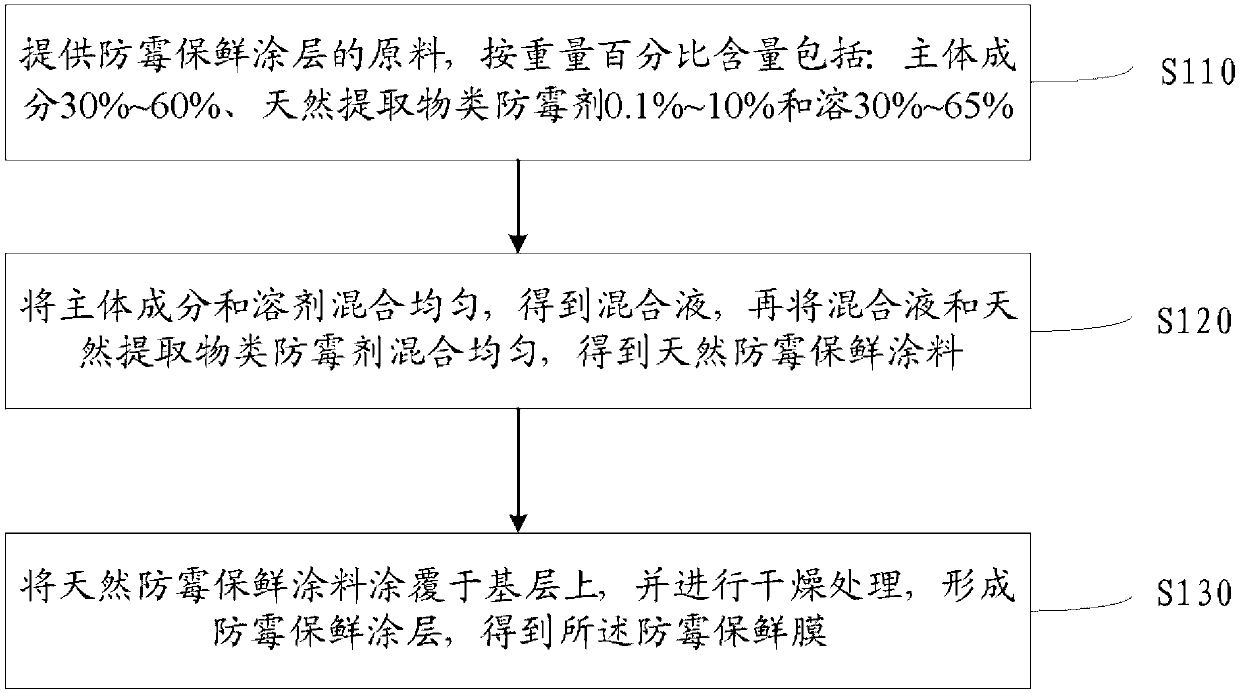

[0040] Please refer to image 3 , the present application also provides a method for preparing an anti-mold plastic wrap in an embodiment, including the following steps S110-S130.

[0041] S110: Provide raw materials for the anti-mold and fresh-keeping coating, including: 30%-60% of the main component, 0.1%-10% of the natural extract anti-fungal agent and 30%-65% of the solvent.

[0042] Specifically, the main component is selected from at least one of modified starch, water-soluble chitosan, modified agar, modified rosin and rosin derivatives, and the solvent is water or / and ethanol.

[0043] S120: uniformly mix the main component and the solvent to obtain a mixed liquid, and then uniformly mix the mixed liquid with a natural extract antifungal agent to obtain an antifungal and fresh-keeping coating.

[0044] It can be understood that in order to accelerate the dissolution, heating, stirring or ultrasonic treatment can be used during the mixing process.

[0045] Specificall...

Embodiment 1

[0054] The raw materials are provided, and the content by weight percentage includes: 30% of water-soluble chitosan, 9% of capsaicin, 0.5% of catechin, 0.3% of allicin, 0.2% of xanthanin and 60% of water.

[0055] Add the water-soluble chitosan and water into the reaction kettle, stir and mix evenly to obtain the mixed solution.

[0056] At a stirring speed of 800r / min, add capsaicin, catechin, allicin and xanthoxylin into the mixture successively dropwise. After the dropwise addition, continue to stir for 6 hours and mix evenly to obtain the anti-mildew and fresh-keeping coating.

[0057] After the anti-mildew fresh-keeping coating is ultrasonically oscillated for 20 minutes, press 6g / m 2 The amount is coated on one side of the PLA film by coating, and then treated at 85°C, 95°C, 120°C, 100°C, and 80°C for 1.5s respectively to obtain a mildew-resistant plastic wrap.

Embodiment 2

[0059] The raw materials are provided, and the content by weight percentage includes: 40% of water-soluble chitosan, 3% of capsaicin, 0.4% of catechin, 0.3% of gingerol, 0.2% of xanthanin, 0.1% of allicin and 56% of water.

[0060] Add the water-soluble chitosan and water into the reaction kettle, stir and mix evenly to obtain the mixed solution.

[0061] At a stirring speed of 1000r / min, add capsaicin, catechin, gingerol, allicin and xanthoxylin into the mixture successively. After the addition, continue to stir for 4 hours and mix evenly to obtain the anti-mold Preservative coating.

[0062] After the anti-mildew fresh-keeping coating is ultrasonically oscillated for 30 minutes, press 3g / m 2 The amount is coated on the upper surface of the PLA film by coating, and treated at 80°C, 90°C, 110°C, 95°C, and 80°C for 1s respectively; then press 3g / m 2 The amount is coated on the lower surface of the PLA film in the form of coating, and treated at 80°C, 90°C, 110°C, 95°C, and 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com