Nanometer Ag3PO4-modified and TiO2 heterojunction photo-catalytic membrane material and preparing method thereof

A photocatalytic film, heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, coatings, etc., can solve the problem of reduced photocatalytic efficiency, large forbidden band width, and high electron-hole pair recombination efficiency. The problem is that the method is simple, the absorption of light is improved, and the photocatalytic degradation efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

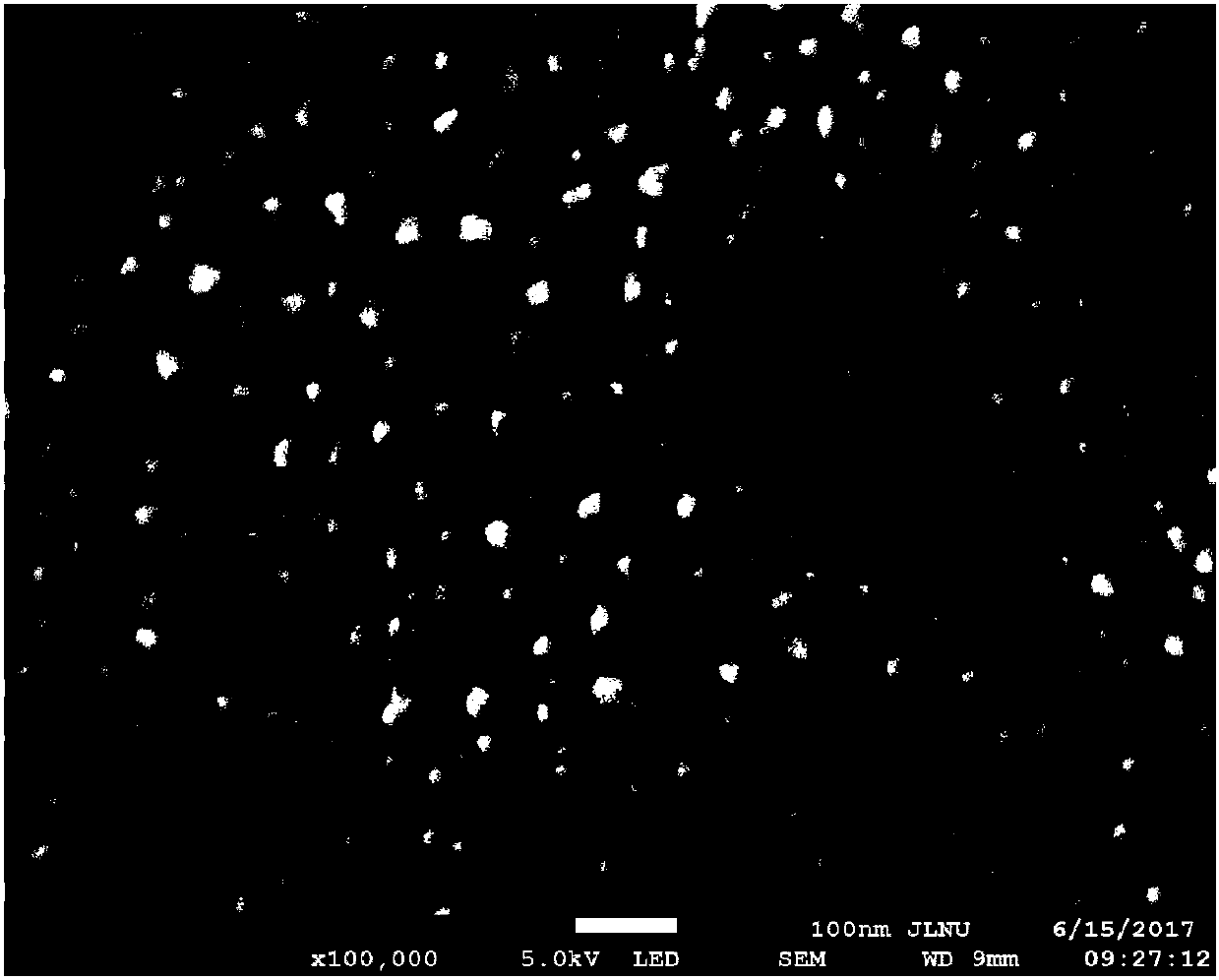

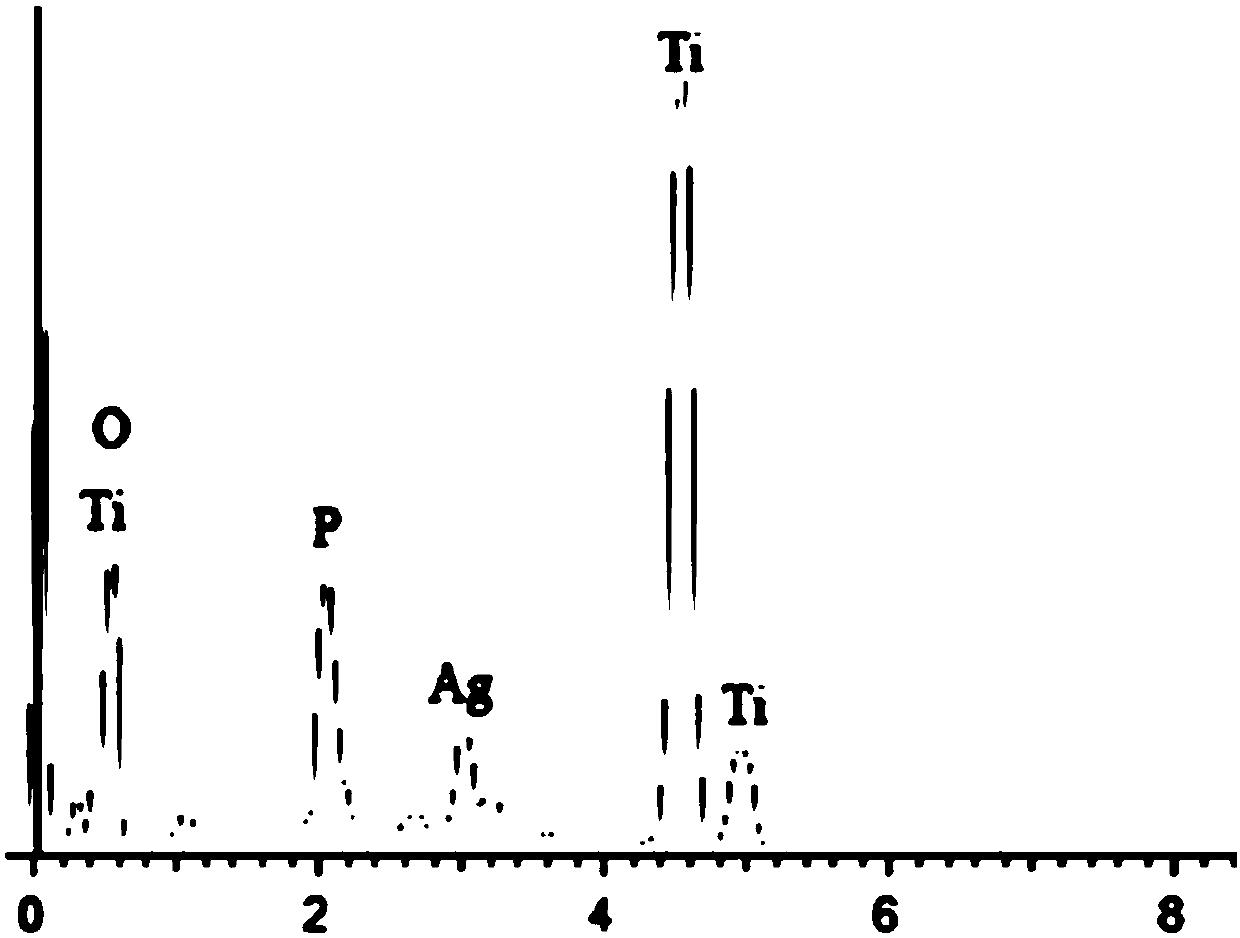

[0034] A kind of nano-Ag in the present embodiment 3 PO 4 Modified TiO 2 A method for preparing a heterojunction photocatalytic film layer material, comprising the steps of:

[0035] S1, put 2cm 2 The pure titanium sample was treated with acid solution to remove oil and scale, and then ultrasonically cleaned in ethanol and deionized water for 5 minutes;

[0036] S2, using a bidirectional pulse power supply, using a pure titanium sample as an anode, a stainless steel electrolytic cell as a cathode, and a solution containing trisodium phosphate, ethylenediaminetetraacetic acid disodium salt, potassium hydroxide and silver nitrate as an electrolyte, under stirring conditions The micro-arc oxidation treatment is carried out under the following conditions; the configuration scheme of the electrolyte is to dissolve 8g of trisodium phosphate, 2g of ethylenediaminetetraacetic acid disodium salt and 1g of potassium hydroxide in 0.5L of deionized water to configure A solution, and 0....

Embodiment 2

[0040] S1, put 2cm 2 The pure titanium sample was treated with acid solution to remove oil and scale, and then ultrasonically cleaned in ethanol and deionized water for 5 minutes;

[0041] S2, using a bidirectional pulse power supply, using a TC4 titanium alloy sample as an anode, a stainless steel electrolytic cell as a cathode, and a solution containing trisodium phosphate, ethylenediaminetetraacetic acid disodium salt, potassium hydroxide and silver nitrate as an electrolyte, in The micro-arc oxidation deposition process was carried out under stirring conditions; the configuration of the electrolyte solution was to dissolve 8g of trisodium phosphate, 4g of ethylenediaminetetraacetic acid disodium salt and 2g of potassium hydroxide in 0.5L of deionized water to prepare A solution, and 1g Dissolve silver nitrate in 0.5L deionized water to prepare solution B. Slowly add solution B to solution A to obtain a clear electrolyte. The power supply mode adopts the constant voltage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com