Method for quantitatively detecting glutathione by using labeling-free copper-indium-sulfur fluorescent probe synchronous fluorescence method

A glutathione and fluorescent probe technology, applied in the field of quantitative detection of biological thiol glutathione, can solve problems such as poor symmetry, low accuracy and sensitivity, incompleteness, etc., and achieve simplified synthesis steps, improved sensitivity, Resolve the effect of incomplete peak shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

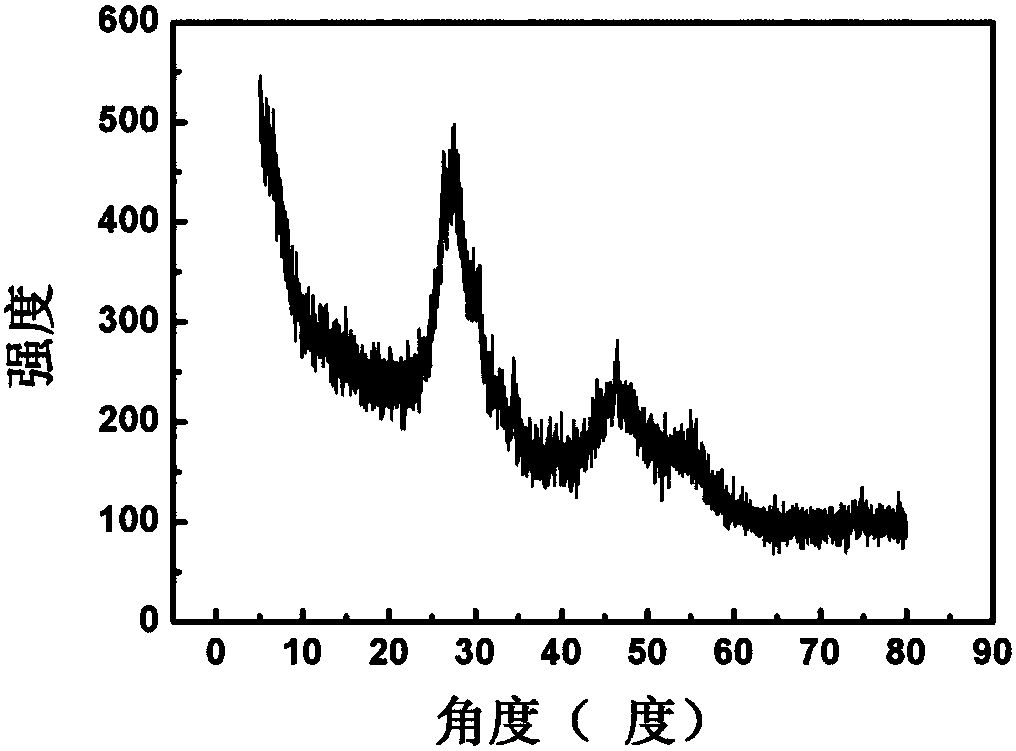

[0028] Example 1: Synthesis of copper indium sulfur quantum dots

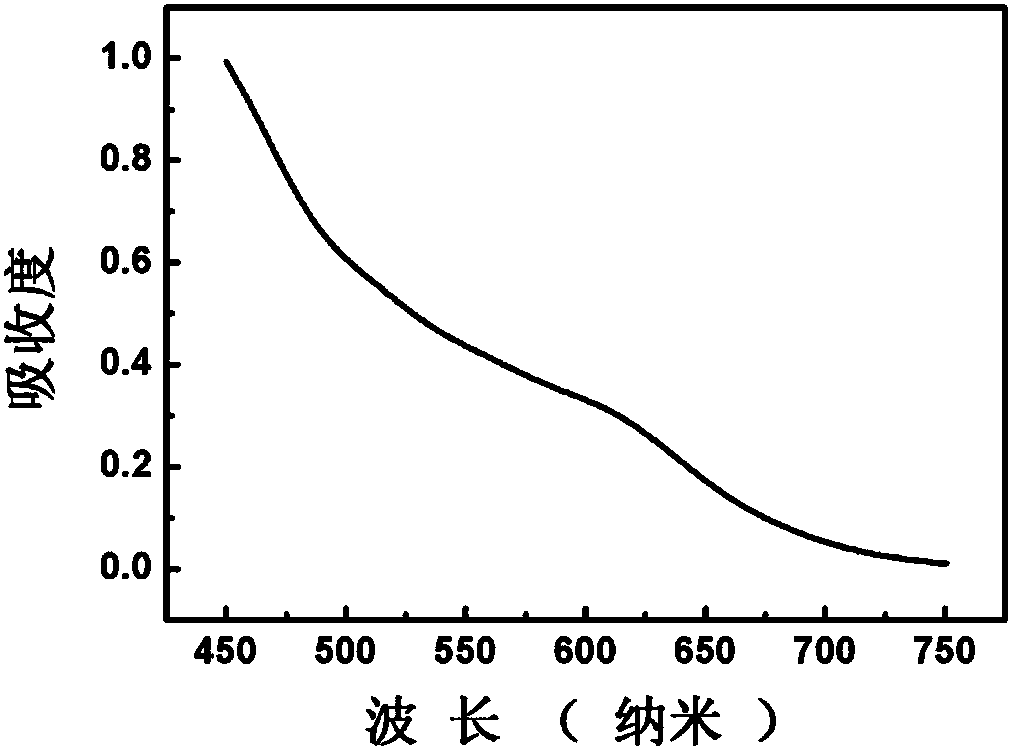

[0029] Weigh 0.0256g CuCl respectively 2 ·2H 2 O and 0.0573g In(NO 3 ) 3 ·5H 2 O was dissolved in 10.5 mL of high-purity water. After being fully dissolved, 157 μL of 3-mercaptopropionic acid was added dropwise to the system with a pipette. At this time, the solution changed from a colorless, clear and transparent state to a light yellow precipitate. Then use 2mol / L NaOH solution to adjust pH=11.3. In the process of adjusting the pH, it is obvious that the precipitation gradually disappears until it returns to a colorless and clear solution state. After the magnet is stirred for 10 minutes, add 0.0228 g of thiourea and continue stirring until it is completely dissolved. Transfer the synthetic solution to a polytetrafluoroethylene reactor and place it in an oven at 150°C for 21 hours and allow it to cool to room temperature naturally. A light yellow clear solution can be obtained, indicating that the copper indiu...

Embodiment 2

[0032] Example 2: Solution configuration

[0033] (1) Preparation of copper indium sulfur quantum dot mother liquor: accurately weigh 0.0190g of purified copper indium sulfur quantum dot powder, dissolve it in 10 mL of high-purity water, and shake it up for use;

[0034] (2) Configuration of 0.2mol / L, 25℃, pH=7.4 PBS buffer solution:

[0035] ①0.2mol / L Na 2 HPO 4 Solution: Weigh 0.716g Na 2 HPO 4 ·12H 2 O is dissolved in 10mL high purity water; ②0.2mol / L NaH 2 PO 4 Solution: weigh 0.312g NaH 2 PO 4 ·2H 2 O is dissolved in 10mL high-purity water; ③take 1.9mL NaH 2 PO 4 Solution and 8.1mL Na 2 HPO 4 Solution, dilute to 20mL, store in the refrigerator for later use;

[0036] (3) The configuration of different concentrations of copper chloride solution:

[0037] Accurately weigh 0.8541g of copper chloride and dissolve it in 5mL of high-purity water to prepare CuCl with a concentration of 1M 2 Solution; respectively take 25μL, 50μL, 75μL, 100μL, 125μL, 150μL, etc. (1M) CuCl 2 The solution is...

Embodiment 3

[0040] Example 3: The synchronous fluorescence method is used as the detection method, and the copper indium sulfur quantum dots are used for specific detection of glutathione to determine the detection time (using a fluorometer for Agilent)

[0041] (1) Add 180μL copper indium sulfur quantum dot mother liquor to the centrifuge tube, 200μL (0.02mol / L) PBS solution and mix well, then add 40μL a series of gradient concentration (0.1mM-1M) copper ion solution (chlorine As the fluorescence quencher, add high-purity water to make the volume to 4 mL. After shaking well and standing for different time, adjust the fluorescence spectrophotometer to the detection mode of synchronous fluorescence method, and set the displacement difference to 60nm for detection.

[0042] (2) Add 180μL of copper indium sulfur quantum dot mother liquor to the centrifuge tube, 200μL (0.02mol / L) PBS solution and mix well, then add 40μL (1mM) copper ion solution as the fluorescence quencher, shake well Let it sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com