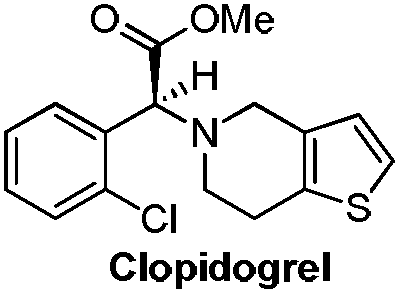

Deuterated thienopyridine derivative, and preparation method and application thereof

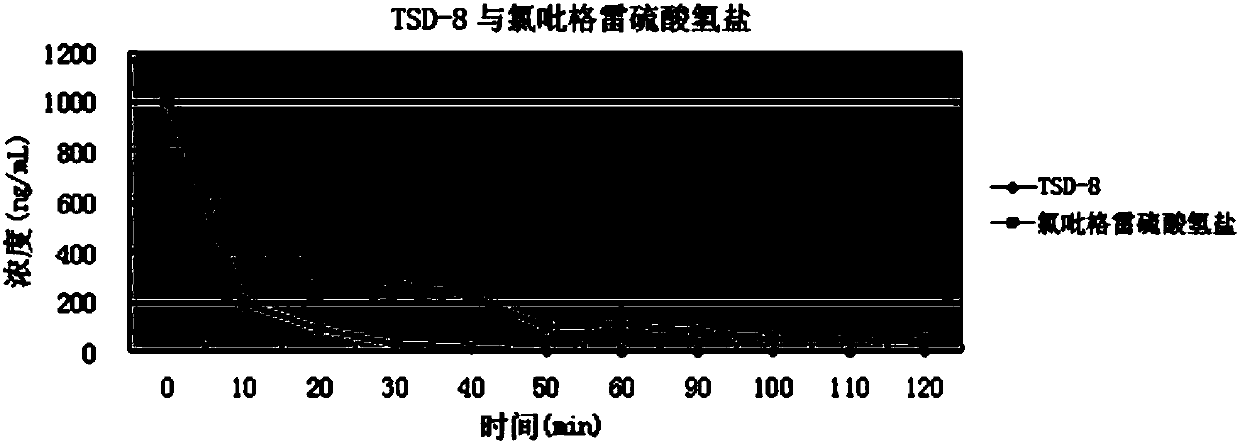

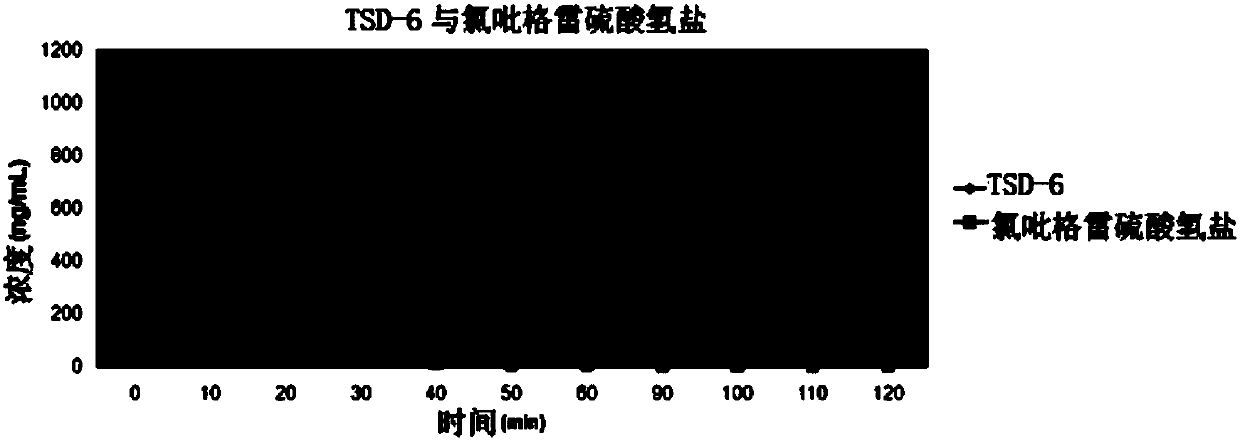

A technology of phenopiperidine and phenopiperidine phosphate, which is applied in the application field of deuterated thienopiperidine derivatives and the preparation of drugs for the treatment and prevention of cardiovascular and cerebrovascular diseases, can solve the problem of fast hydrolysis rate, inhibition of platelet aggregation low rate issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (R)-Deuterated methyl o-chloromandelic acid

[0045]

[0046] Dissolve 9.4 g of (R)-o-chloromandelic acid in 36 mL of deuterated methanol, add 1 mL of 4M hydrogen chloride / dioxane solution, and heat to reflux for 5 hours. After cooling, the solvent is evaporated under reduced pressure, and the remainder is dissolved in dichloromethane , Washed with 5% potassium carbonate aqueous solution and water in turn, dried the dichloromethane solution with anhydrous sodium sulfate, filtered to remove the desiccant and evaporated to dryness to obtain a colorless transparent oily substance (R)-deuterated methyl o-chloromandelic acid 9.2g , The yield was 89.7%.

Embodiment 2

[0048] (R)-2-(2-Chlorophenyl)-2-(4-nitrobenzenesulfonyloxy)-acetic acid deuterated methyl ester (Ⅱ-1)

[0049]

[0050] Dissolve 10.2g of (R)-o-chloromandelic acid deuterated methyl ester in 50mL of anhydrous dichloromethane, add 65.6g of triethylamine and catalytic amount of DMAP, stir, cool to 0℃, and add 12.2g dropwise at the same temperature A solution of p-nitrobenzenesulfonyl chloride in 50 mL of anhydrous dichloromethane was then incubated and reacted for 4 hours. Add 100 mL of water to the reaction solution, stir, let stand, and separate. The aqueous phase was extracted three times with 150 mL of dichloromethane. The organic phases were combined and dried over anhydrous sodium sulfate. After filtering to remove the desiccant, the dichloromethane was evaporated under reduced pressure. 20.9 g of dark red oily crude product was obtained, and 15.8 g of solid product (II-1) was obtained by methanol recrystallization, with a yield of 81.3%.

Embodiment 3

[0052] (2S)-2-(2-chlorophenyl)-2-(2-oxo-7,7a-dihydrothieno[3,2-c]pyridine-5(2H,4H,6H)-yl) -Deuterated methyl acetate (V-1)

[0053]

[0054] (R)-2-(2-chlorophenyl)-2-(4-nitrobenzenesulfonyloxy)-acetic acid deuterated methyl ester (II-1) 58.1g (0.15mol), 5,6, 7,7a-Tetrahydrothieno[3.2-c]pyridine-2(4H)-one hydrochloride (Ⅳ-1) 32.3g (0.17mol) and 37.8g (0.38mol) potassium bicarbonate were added to 500mL acetonitrile The reaction system was protected with nitrogen and stirred at room temperature for 26 hours. After the reaction solution is allowed to stand, the insoluble matter is filtered to obtain a dark red mother liquor. The solvent was evaporated to dryness under reduced pressure, and 35.4 g of oily product was obtained by flash column chromatography (petroleum ether: ethyl acetate=4:1) with a yield of 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com