Method of separating rhenium and/or osmium from crude oil

A crude oil and element technology, applied in the field of separating rhenium and/or osmium elements, can solve the problems of affecting accuracy, affecting the accuracy of determining geological age, affecting the accuracy of geological age, etc., and achieving the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

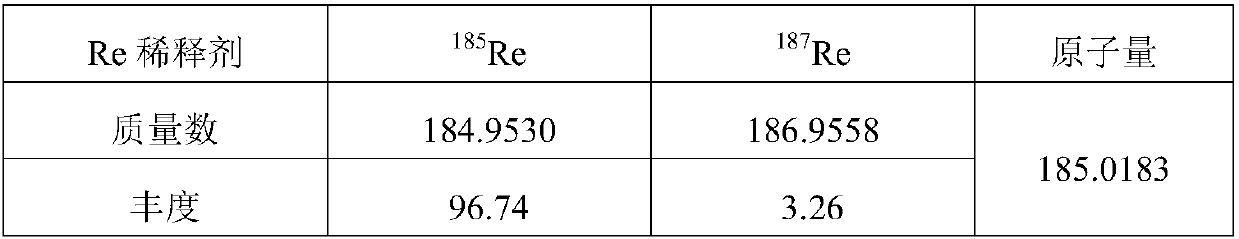

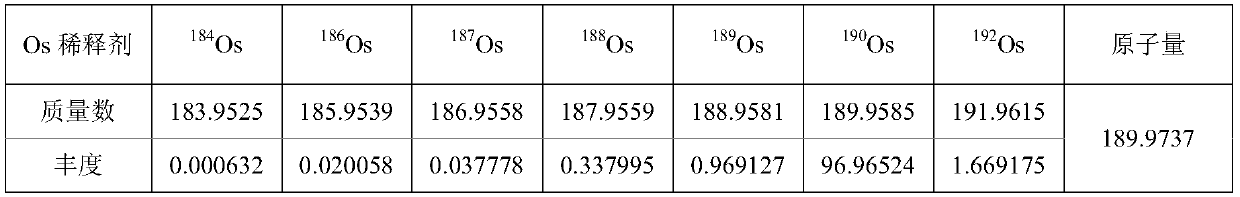

[0029] Add 5 times the volume of ultrapure water to a certain amount of crude oil sample, extract and separate at room temperature for 4 hours, then centrifuge for 60 minutes in a centrifuge, filter with filter paper to separate and remove the aqueous solution and possible inorganic minerals. Weigh the separated oil sample, add n-pentane in a volume ratio of 1:4, and dissolve in ultrasonic for 4 hours to precipitate asphaltenes. Centrifuge on a centrifuge for 15 minutes (2000 rpm) to separate the asphaltenes. After the solvent evaporates and dry, weigh about 0.2 g of the asphaltene sample into the Carlos tube, freeze with ethanol + liquid nitrogen, and add an accurate weighing Take the Re-Os mixed diluent, add 2mL concentrated HCl, 5mL concentrated HNO 3 , 2mL H 2 O 2 (Mass fraction 30%), then put the sealed Carlos tube with a steel sleeve and put it in the oven, and use the temperature program to digest the sample. The temperature will be increased from room temperature to 120℃...

Embodiment 2

[0036] Accurately weigh approximately 0.2g of the crushed solid asphalt sample (accurate to 0.00001g), transfer it into the Carlos tube through a glass long-necked funnel, freeze the Carlos tube with ethanol + liquid nitrogen, add the accurately weighed Re-Os to mix and dilute Use 2mL HC1 to completely flush the mixed diluent to the bottom of the Carlos tube in two times, add liquid nitrogen to the insulation barrel to ensure that the solution in the Carlos tube is frozen, then add 5mL HNO 3 And pay attention to the use of HNO 3 Rinse the sample powder that may remain on the mouth of the funnel; wait for HNO to be added 3 After freezing, add 2mL H 2 O 2 . During this process, observe the solution in the Carlos tube at any time, replenish the liquid nitrogen, keep it frozen, and seal the tube with a LPG-oxygen flame.

[0037] After the solution in the lower part is thawed, put the steel jacket on and put it in the oven, use the temperature program to digest the sample, increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com