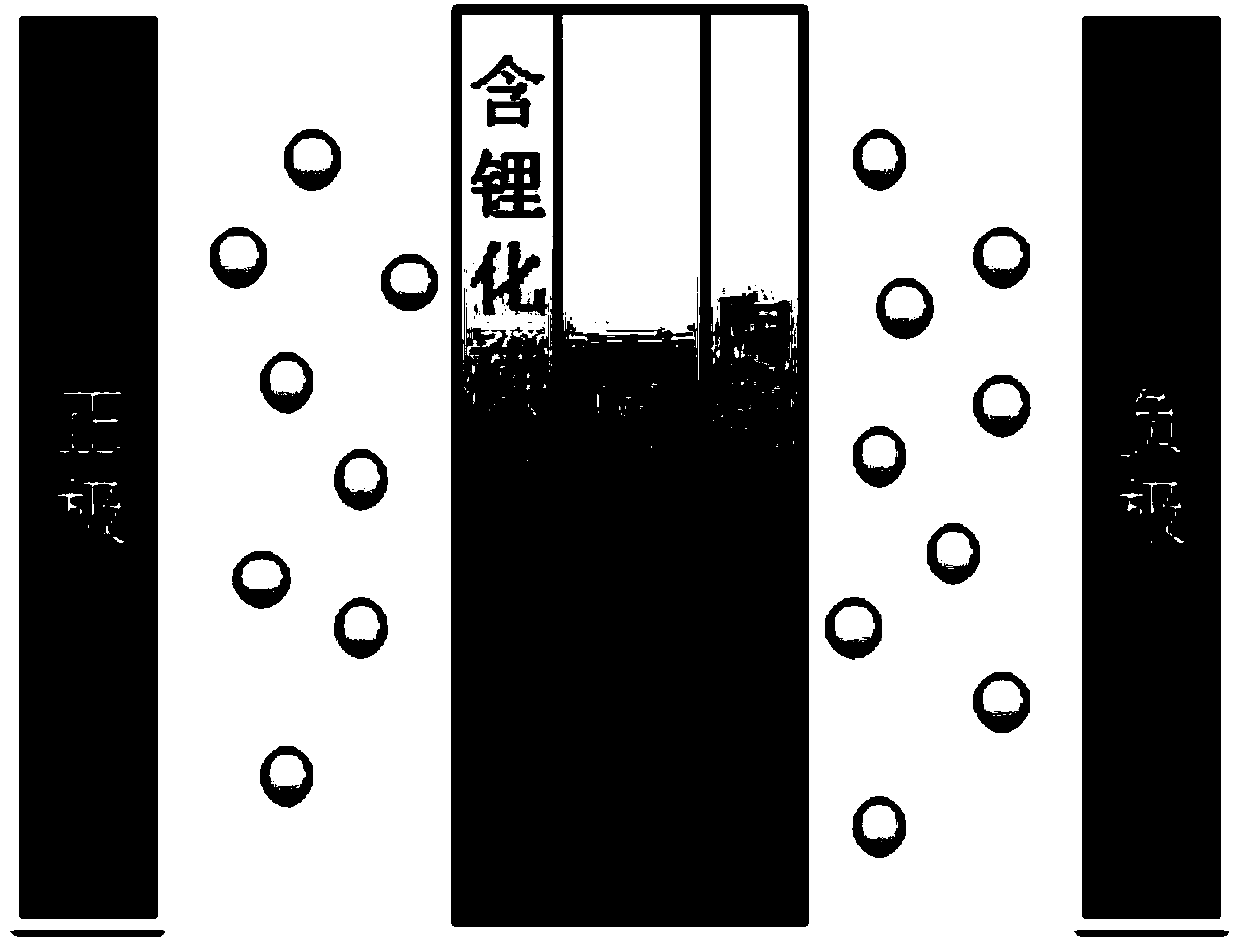

Composite coated diaphragm for high-nickel ternary lithium-ion battery and preparation method thereof

A lithium-ion battery and separator technology, applied in the field of composite coating separator and its preparation, can solve the problems of decreased material/electrolyte interface stability, increase of battery internal pressure and temperature, affecting material cycle stability, etc. Large-scale application, inhibition of decomposition, and the effect of facilitating the promotion and application of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add nanometer α-alumina powder and LA133 with a mass ratio of 80:20 to a certain amount of water for stirring and dispersion to obtain a mixed slurry with a solid content of 61%, and then coat the slurry on the PP / PE composite diaphragm base On one side of the material, the coating thickness was measured after drying and rolling. Then take artificial graphite containing lithiated sulfonic acid groups, carbon nanotubes, and polyvinylidene fluoride with a mass ratio of 90:5:5, and add them to a certain amount of N-methylpyrrolidone to stir and mix the slurry to obtain a solid content of 52%. The mixed slurry is uniformly coated on the other side of the diaphragm, dried and rolled to obtain the desired composite coated diaphragm.

Embodiment 2

[0027] Add nano α-alumina powder and gelatin with a mass ratio of 75:25 to a certain amount of water for stirring and dispersion to obtain a mixed slurry with a solid content of 64%, and then coat the slurry on one side of the PP diaphragm substrate On, coating thickness was measured after drying and rolling. Add activated carbon containing lithiated sulfonic acid groups, Super P, and polytetrafluoroethylene with a mass ratio of 82:8:10 to a certain amount of N-methylpyrrolidone and stir to make a slurry to obtain a positive electrode with a solid content of 58%. Slurry, the slurry is evenly coated on the other side of the separator, dried and rolled to obtain the desired composite coated separator.

Embodiment 3

[0029] Add nano α-alumina powder and sodium alginate with a mass ratio of 90:10 to a certain amount of water for stirring and dispersion to obtain a mixed slurry with a solid content of 59%, and then coat the slurry on the PE diaphragm substrate On one side, the coating thickness was measured after drying and rolling. Then take the microporous carbon containing lithiated sulfonic acid groups, Ketjen black, and sodium carboxymethyl cellulose with a mass ratio of 95:3:2 and add them to a certain amount of water for stirring and slurrying to obtain a solid content of 65%. Positive electrode slurry, the slurry is evenly coated on the other side of the diaphragm, dried and rolled to obtain the required composite coating diaphragm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com