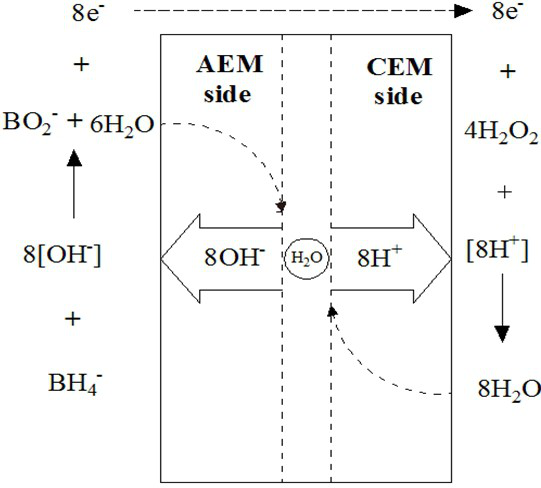

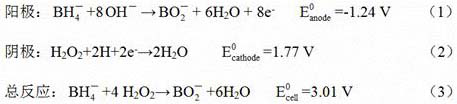

A Bipolar Membrane Direct Borohydride Fuel Cell

A borohydride and fuel cell technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve problems such as borohydride leakage and lack of stability, reduce polarization loss, eliminate mixed potential, The effect of improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A bipolar membrane-type direct borohydride fuel cell, the preparation process of the bipolar membrane used: 2 mmmol polyvinylpyrrolidone is dissolved in water, and the aqueous solution of polyvinylpyrrolidone having a concentration of 2 mmol / L is fabricated, and then 20 Moistrate nickel nickel nickel is added to a water solution of polyvinylpyrrolidone, and stir evenly, the intermediate interface layer membrane is obtained. Take a piece of anion exchange membrane (JAM-II-07, Beijing Jie Rui), uniformly coated on the surface of the anion exchange membrane, and after drying for 2 minutes, the Nafion 212 ion exchange film (Dupont) On it, it was hot for 2 minutes at 0.5 MPa 60 ° C, and the bipolar film was obtained, and the prepared bipolar membrane was stored in ultrapure water.

[0039] With the obtained bipolar film as a diaphragm, the battery performance evaluation is performed at room temperature, the battery performance evaluation is performed. The open circuit voltage ...

Embodiment 2

[0041] A bipolar membrane type direct borohydride fuel cell, the electrolytic liquid separator is a bipolar film, and the preparation process of the bipolar membrane used is: 2 mmmmol polyvinylpyrrolidone is dissolved in water, and the concentration is 2 mmol / L. Polyvinylpyrrolidone aqueous solution, then 20 mmorate cobalt glycobalt is added to a water solution of polyvinylpyrrolidone, and the intermediate interface layer membrane is produced even after stirring. Take a piece of anion exchange membrane (Twedai, Shandong Tianwei), evenly coated with an intermediate interface layer membrane solution on the surface of the anion exchange membrane, after drying for 2 minutes, pressing the Nafion 115 ion exchange membrane on it, at 0.5 MPa At 60 ° C for 2 minutes, a bipolar film was obtained, and the prepared bipolar membrane was stored in ultrapure water.

[0042] With the obtained bipolar film as a diaphragm, the battery performance evaluation is performed at room temperature, and t...

Embodiment 3

[0044] A bipolar membrane type direct borohydride fuel cell, the electrolytic liquid separator is a bipolar film, and the preparation process of the bipolar membrane used is: 2 mmmmol polyvinylpyrrolidone is dissolved in water, and the concentration is 2 mmol / L. Polyvinylpyrrolidone aqueous solution, and then add 20 mmolitrate iron to aqueous solution of polyvinylpyrrolidone, stir well and uniformly produce an intermediate interface layer membrane. Take a piece of anion exchange membrane (HAM concentrate, Yi Chen Technology), uniformly coated on the surface of the anion exchange membrane, and after drying for 2 minutes, press the Nafion 117 ion exchange film (Dupont) On it, it was 2 minutes at 0.5 MPa 60 ° C, and the bipolar film was obtained, and the prepared bipolar membrane was stored in ultrapure water.

[0045] With the obtained bipolar film as a diaphragm, the battery performance evaluation is performed at room temperature, and the battery performance evaluation is perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com