Preparation method for temperature compensation attenuator

A technology of temperature compensation and attenuator, applied in waveguide devices, electrical components, circuits, etc., can solve the problem of process and performance controllability, low repeatability and consistency, and insufficient precision of thickness and graphic line width/line distance , Parasitic capacitive reactance affects the high-frequency performance of the device, etc., to achieve the effect of shortening the response time constant, excellent consistency and repeatability, and facilitating miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In order to overcome the limitations of the existing thick-film process for preparing temperature-compensated attenuators and improve the performance of temperature-compensated attenuators, the present invention provides a method for preparing temperature-compensated attenuators, which includes the following steps:

[0046] (1a) Depositing PTC thermistors on the substrate by thin film technology, patterning the PTC thermistors, retaining the required parts of the design, and performing heat treatment on the PTC thermistors;

[0047] (2a) Depositing NTC thermistors on the substrate by thin film technology, patterning the NTC thermistors, retaining the required parts of the design, and performing heat treatment on the NTC thermistors;

[0048] (3a) Depositing metal electrodes on the substrate by a thin film process, and patterning the metal electrodes to obtain a temperature compensation attenuator; or

[0049] (1b) Deposit PTC thermistors on the substrate by thin film te...

Embodiment 1

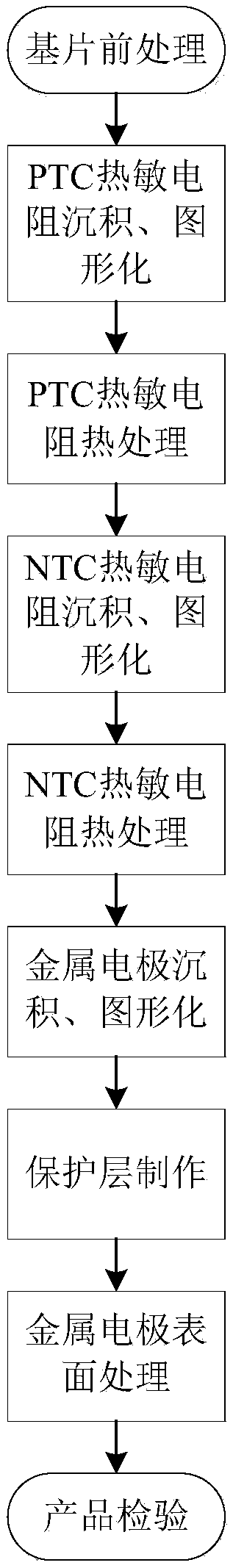

[0073] An embodiment of the preparation method of the temperature compensation attenuator of the present invention, the preparation process of the temperature compensation attenuator described in this embodiment is as follows figure 1 As shown, the specific method is as follows:

[0074] (1) First, pre-treat the substrate: according to the requirements of power, frequency and device size, alumina, aluminum nitride, and beryllium oxide ceramics can be selected. For general applications, 99.6% alumina ceramic substrates are the first choice; sequentially use Ultrasonic cleaning of the substrate with acetone, absolute ethanol, and deionized water for 5 minutes each, and drying with nitrogen for later use; for occasions with higher requirements, a step of plasma cleaning can be added to improve the cleanliness of the substrate surface;

[0075] (2) The PTC thermistor is deposited on the substrate by thin film technology, the PTC thermistor is patterned, the required part of the d...

Embodiment 2

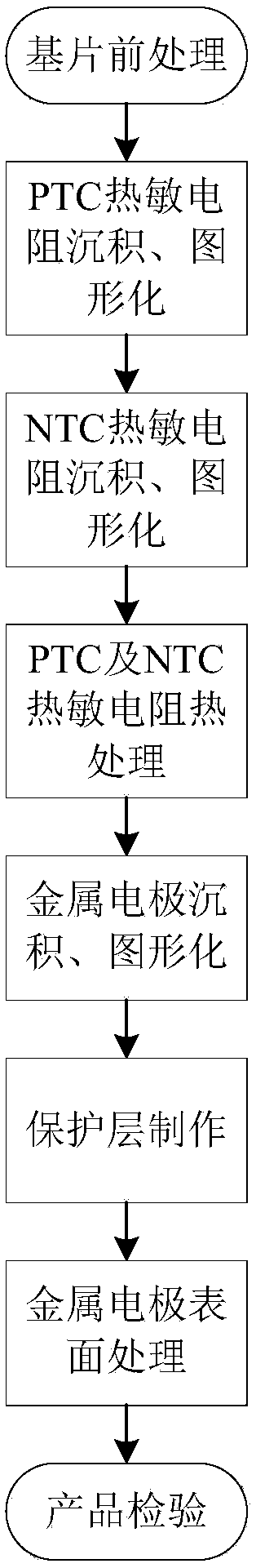

[0082] An embodiment of the preparation method of the temperature compensation attenuator of the present invention, the preparation method of the temperature compensation attenuator described in this embodiment is to combine the heat treatment of the PTC thermistor and the NTC thermistor in embodiment 1 to simplify the process, Reduce costs while avoiding the impact of secondary heat treatment on thermistor performance. The preparation process of the temperature compensation attenuator described in this embodiment is as follows figure 2 As shown, the specific method is as follows:

[0083] (1) First, pre-treat the substrate: according to the requirements of power, frequency and device size, alumina, aluminum nitride, and beryllium oxide ceramics can be selected. For general applications, 99.6% alumina ceramic substrates are the first choice; sequentially use Ultrasonic cleaning of the substrate with acetone, absolute ethanol, and deionized water for 5 minutes each, and dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com