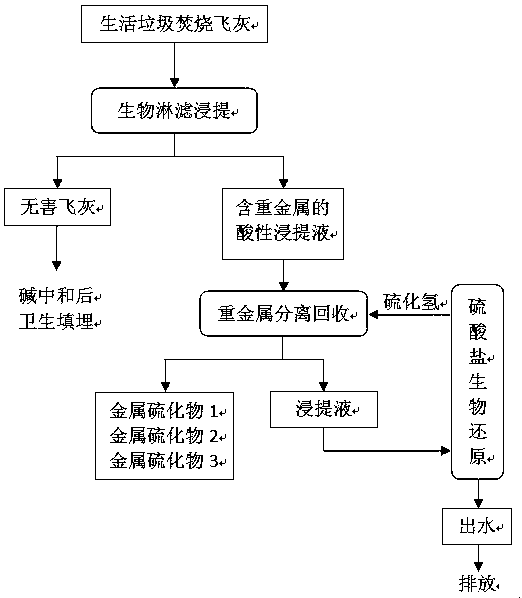

Garbage incineration fly ash hazard-free treatment and heavy metal recycling method

A waste incineration fly ash and heavy metal technology, which is applied in the field of environmental engineering, can solve the problems of unfavorable resource utilization of heavy metals, and achieve the effects of high resource utilization performance, simple process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0023] Domestic waste incineration fly ash was taken from a waste incineration power plant in Shandong. The main heavy metal contents were: Zn 31.3 g / kg, Cu4.83g / kg, Pb 4.04g / kg, Cr 4.01g / kg, Cd 298 mg / kg, Ni 215 mg / kg.

[0024] The specific processing steps are as follows:

[0025] (1) Preparation of recyclable sulfur and bioleaching of domestic waste incineration fly ash

[0026] Commercially available sulfur powder was heated to 120°C on an electric furnace and kept for 20 min. The obtained molten sulfur was poured into distilled water at 20°C while stirring continuously. The molten sulfur formed sulfur balls with a diameter of about 3.0 mm. The sulfur balls are separated from the water and dried at room temperature to obtain recyclable sulfur.

[0027] The biological leaching bacteria are mixed acidophilic sulfur oxidizing bacteria, and the source of the bacteria is the soil around a copper mine in Henan; the composition of the medium is (g / L): KH 2 PO 4 3.0, CaCl 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com