Preparation method of cuprous oxide nanocrystals

A technology of cuprous oxide and nanocrystals, applied in the direction of copper oxide/copper hydroxide, etc., to achieve the effects of mild and controllable conditions, cheap and easy-to-obtain raw materials, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 1 mL of aqueous copper sulfate solution with a concentration of 0.01 mol / L in a mixed solution of 10 mL of water and 0.5 mL of oleic acid, stir well and add 1 mL of aqueous sodium hydroxide solution with a concentration of 0.1 mol / L, then heat the reaction solution to 50 ℃. After the temperature stabilized, 1 mL of a 0.01 mol / L sodium ascorbate aqueous solution was added, followed by continuous stirring for 1 hour. After the reaction, the reaction solution was centrifuged at 8000 rpm, and the separated solid was washed with a mixed solvent of ethanol and cyclohexane, and the washing process was repeated three times. Finally, the solid obtained by centrifugation was vacuum-dried at room temperature to obtain orange oxide Cuprous powder.

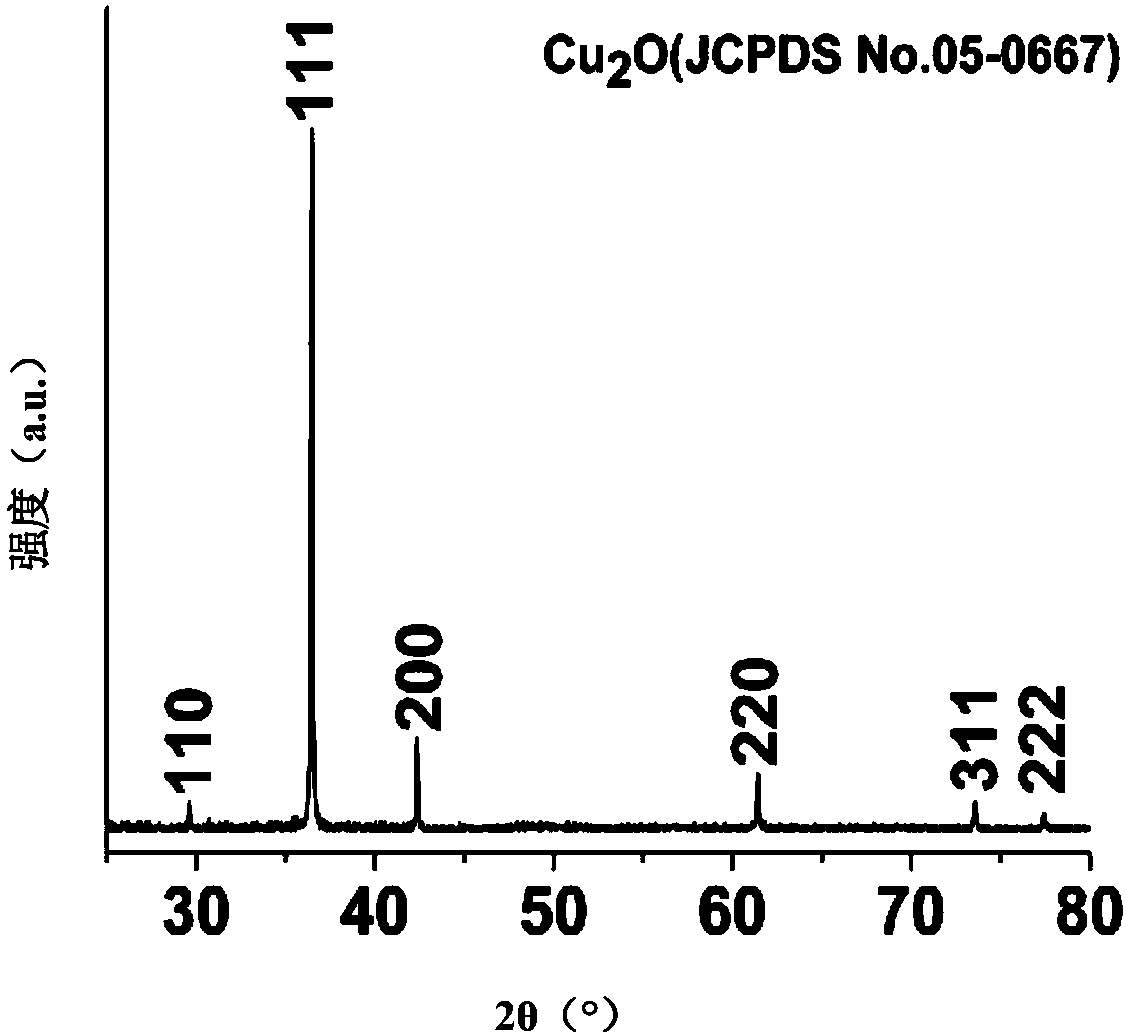

[0026] figure 1 It is the XRD pattern of the cuprous oxide grains obtained in Example 1, which is consistent with the standard XRD pattern of cuprous oxide, proving that the obtained in Example 1 is cuprous oxide.

[0027] ...

Embodiment 2

[0029] Dissolve 1 mL of copper acetate aqueous solution with a concentration of 0.1 mol / L in a mixed solution of 10 mL of water and 0.5 mL of oleic acid, stir well, add 1 mL of aqueous potassium hydroxide solution with a concentration of 1 mol / L, and then heat the reaction solution to 60°C . After the temperature stabilized, 1 mL of 0.1 mol / L ascorbic acid aqueous solution was added, followed by continuous stirring for 2 hours. After the reaction, the reaction solution was centrifuged at 8000 rpm, and the separated solid was washed with a mixed solvent of ethanol and cyclohexane, and the washing process was repeated three times. Finally, the solid obtained by centrifugation was vacuum-dried at room temperature to obtain orange oxide Cuprous powder.

[0030] The obtained orange cuprous oxide was characterized by XRD and XRD, and the characterization result was similar to that of Example 1.

Embodiment 3

[0032] Dissolve 1 mL of a mixed aqueous solution of copper acetate and copper sulfate with a concentration of 0.5 mol / L in a mixed solution of 10 mL of water and 0.5 mL of oleic acid, stir well and add 1 mL of potassium hydroxide and sodium hydroxide with a concentration of 0.5 mol / L to mix aqueous solution, and then the reaction solution was heated to 56°C. After the temperature stabilized, 1 mL of a mixed aqueous solution of 0.6 mol / L ascorbic acid and sodium ascorbate was added, followed by continuous stirring for 1.5 hours. After the reaction, the reaction solution was centrifuged at 8000 rpm, and the separated solid was washed with a mixed solvent of ethanol and cyclohexane, and the washing process was repeated three times. Finally, the solid obtained by centrifugation was vacuum-dried at room temperature to obtain orange oxide Cuprous powder.

[0033] The obtained orange cuprous oxide was characterized by XRD and XRD, and the characterization result was similar to that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com