A kind of rare earth ion pair co-doped k 3 y(po 4 ) 2 Up-conversion luminescent material and preparation method thereof

A technology of rare earth ions and luminescent materials, applied in the field of preparation of rare earth doped luminescent materials, can solve the problems of inability to realize temperature measurement, cell temperature detection and temperature measurement, unstable physical and chemical properties of fluoride, and oxygen surface contact sensitivity, etc., and can be widely used. Prospect, low production cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

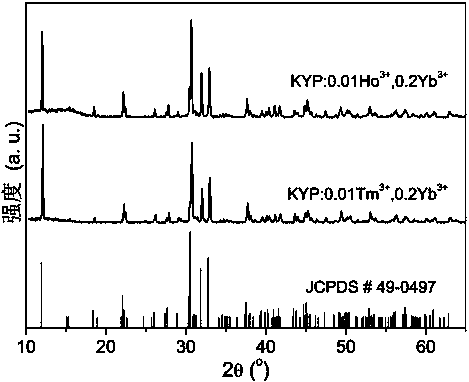

[0035] (1) Weigh 0.2165g K respectively 2 CO 3 , 0.7937g (NH 4 ) 2 HPO 4 , 0.2649gY 2 O 3 , 0.1161gYb 2 O 3 and 0.0057gTm 2 O 3 Put it in an agate mortar, add 6 mL of ethanol to grind the raw material to a thin mud, and mix it evenly;

[0036] (2) Put the ground raw materials in a corundum crucible, place it in a tube furnace, and burn it at 1000 °C for 4 hours in an air atmosphere. After the tube furnace is cooled, take out the crucible and pour the agglomerated sample into K is obtained by grinding into powder in a porcelain mortar 3 Y(PO 4 ) 2 :0.01Tm 3+ -0.2Yb 3+ 1g.

Embodiment 2

[0038] (1) Weigh 0.433gK respectively 2 CO 3 , 1.5874g (NH 4 ) 2 HPO 4 , 0.5298gY 2 O 3 , 0.2322gYb 2 O 3 and 0.0114gTm 2 O 3 Put it in an agate mortar, add 10 mL of ethanol to grind the raw materials to a thin mud, and mix them evenly;

[0039] (2) Put the ground raw materials in a corundum crucible, place it in a chamber furnace, and burn it at 1100 °C for 5 hours under a nitrogen atmosphere. After the tube furnace is cooled, take out the crucible and pour the agglomerated sample into K is obtained by grinding into powder in a porcelain mortar 3 Y(PO 4 ) 2 :0.01Tm 3+ -0.2Yb 3+ 2g.

Embodiment 3

[0041] (1) Weigh 0.2165gK respectively 2 CO 3 , 0.7937g (NH 4 ) 2 HPO 4 , 0.2649gY 2 O 3 , 0.1161gYb 2 O 3 and 0.0057gHo 2 O 3 Put it in an agate mortar, add 6 mL of ethanol to grind the raw material to a thin mud, and mix it evenly;

[0042] (2) Put the ground raw materials in a corundum crucible, place it in a tube furnace, and burn it at 1000 °C for 4 hours in an air atmosphere. After the tube furnace is cooled, take out the crucible and pour the agglomerated sample into K is obtained by grinding into powder in a porcelain mortar 3 Y(PO 4 ) 2 :0.01Ho 3+ -0.2Yb 3+ 1g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com