Preparation method of ZnIn2S4/TiO2 nanotube composite membrane photoanode for photocathodic protection

A technology of photogenerated cathodic protection and znin2s4, which is applied in the direction of superimposed layer plating, liquid chemical plating, electrolytic coating, etc., can solve problems such as difficulty in maintaining good photogenerated cathodic protection effect, low photoelectric efficiency, and reduction of metal corrosion potential, etc., to achieve Good cathodic protection effect, lower corrosion potential, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

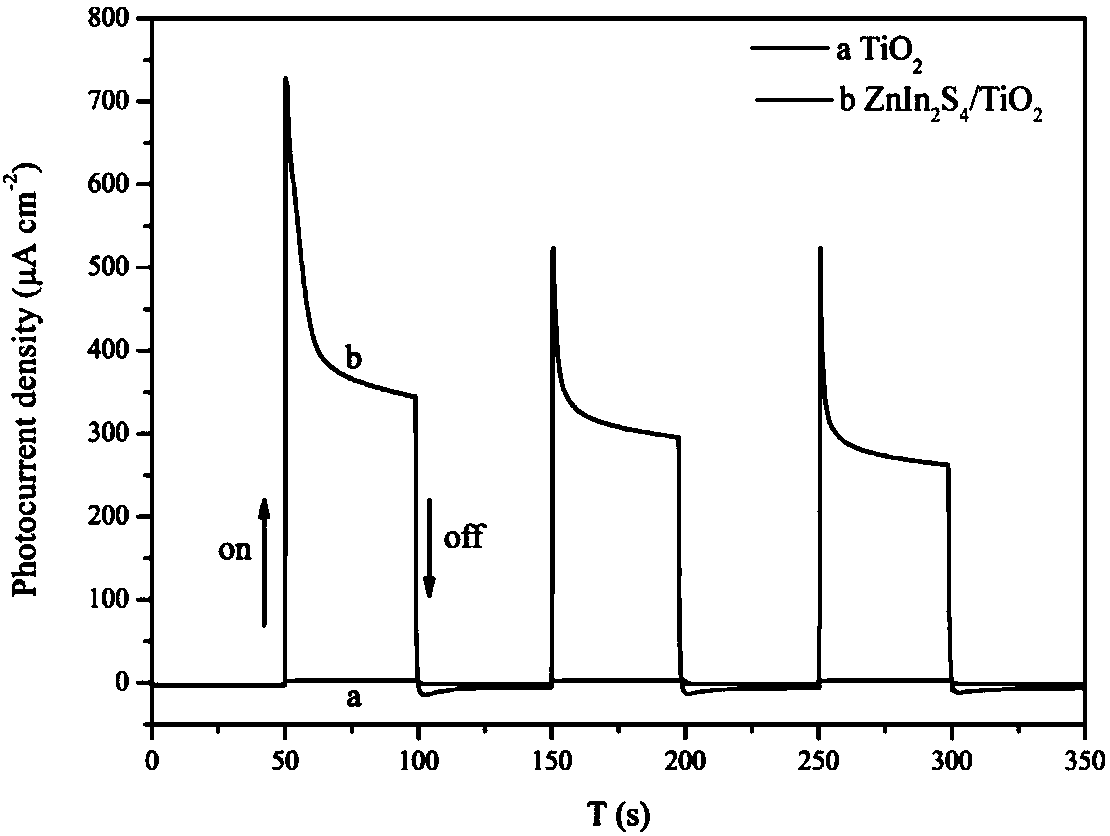

[0041] According to above-mentioned technical scheme (concrete steps), prepare ZnIn 2 S 4 / TiO 2 Nanotube composite film, and test the cathodic protection effect of composite film as photoanode on carbon steel.

[0042] Take a rectangular pure titanium foil with a thickness of 0.1 mm as a sample, its length is 15 mm, and its width is 15 mm. First, the titanium foil is polished with a chemical polishing agent, wherein the polishing agent is 0.45g NH 4 F, 2.5mL H 2 O, 6mL HNO 3 and 6mL H 2 o 2 mixed solution. Then use deionized water, acetone, and absolute ethanol to clean ultrasonically and then dry it for use.

[0043] TiO 2 Preparation of nanotube array film: Weigh 0.45g NH 4 F, dissolved in 8 mL of deionized water, added 80 mL of ethylene glycol and mixed to obtain a mixed solution, to obtain a mixed solution. At room temperature, with the cleaned titanium foil substrate as the anode and the foil as the cathode, anodize at 30V for 2h in the above mixed solution. ...

Embodiment 2

[0051] According to above-mentioned technical scheme (concrete steps), prepare ZnIn 2 S 4 / TiO 2 Nanotube composite film, and test the cathodic protection effect of composite film as photoanode on carbon steel.

[0052] Take a rectangular pure titanium foil with a thickness of 0.1 mm as a sample, its length is 15 mm, and its width is 15 mm. First, the titanium foil is polished with a chemical polishing agent, wherein the polishing agent is 0.45g NH 4 F, 2.5mL H 2 O, 6mL HNO 3 and 6mL H 2 o 2 mixed solution. Then use deionized water, acetone, and absolute ethanol to clean ultrasonically and then dry it for use.

[0053] TiO 2 Preparation of nanotube array film: Weigh 0.45g NH 4 F, dissolved in 8 mL of deionized water, added 80 mL of ethylene glycol and mixed to obtain a mixed solution, to obtain a mixed solution. At room temperature, with the cleaned titanium foil substrate as the anode and the foil as the cathode, anodize at 30V for 2h in the above mixed solution. ...

Embodiment 3

[0062] According to above-mentioned technical scheme (concrete steps), prepare ZnIn 2 S 4 / TiO 2 Nanotube composite film, and test the cathodic protection effect of composite film as photoanode on carbon steel.

[0063] Take a rectangular pure titanium foil with a thickness of 0.1 mm as a sample, its length is 25 mm, and its width is 10 mm. First, the titanium foil is polished with a chemical polishing agent, wherein the polishing agent is 0.45g NH 4 F, 2.5mL H 2 O, 6mL HNO 3 and 6mL H 2 o 2 mixed solution. Then use deionized water, acetone, and absolute ethanol to clean ultrasonically and then dry it for use.

[0064] TiO 2 Preparation of nanotube array film: Weigh 0.45g NH 4F, dissolved in 8 mL of deionized water, added 80 mL of ethylene glycol and mixed to obtain a mixed solution, to obtain a mixed solution. At room temperature, with the cleaned titanium foil substrate as the anode and the foil as the cathode, anodize at 25V for 4h in the above mixed solution. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com