Flexibilizer in breeding net main braid rope stretching preparation

A preparation process and a technology for weaving ropes, applied in the field of toughening agents, can solve the problems of short practical life and non-wear resistance, achieve good service life, improve mechanical properties, and improve fiber toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0025] The toughening agent added during the stretching preparation process of the main braided rope of the breeding net is prepared from the following components: 30 parts of acrylate polymer, 50 parts of styrene-based elastomer grafted with acrylate, and 10 parts of antioxidant , 25 parts of p-aminobenzoic acid, 4 parts of sodium hydroxide, 250 parts of water, 10 parts of zinc oxide, 6 parts of surfactant, 3 parts of sodium metasilicate, 1 part of sodium carbonate, 10 parts of ammonia water, 16 parts of corn oil, 5 parts of thermoplastic polyolefin elastomer graft, 4 parts of polyolefin, 1 part of nylon.

[0026] Parts are parts by weight.

[0027] The surfactant is stearic acid or sodium dodecylbenzenesulfonate or fatty acid glycerides.

[0028] The toughening agent preparation method comprises the following steps:

[0029] Add acrylate polymer, acrylate-grafted styrene elastomer, antioxidant, and water into the reaction kettle, stir at 90°C for 4 hours, cool down to 75°C...

Embodiment 2

[0036] Example 2: The toughening agent added during the stretching preparation of the main braided rope of the breeding net is prepared from the following components: 50 parts of acrylate polymer, 70 parts of styrene-based elastomer grafted with acrylate, anti- 30 parts of oxygen agent, 100 parts of p-aminobenzoic acid, 16 parts of sodium hydroxide, 260 parts of water, 12 parts of zinc oxide, 9 parts of surfactant, 6 parts of sodium metasilicate, 2 parts of sodium carbonate, 12 parts of ammonia water, corn 24 parts of oil, 8 parts of thermoplastic polyolefin elastomer graft, 5 parts of polyolefin, 10 parts of nylon.

[0037] Parts are parts by weight.

[0038] The surfactant is stearic acid or sodium dodecylbenzenesulfonate or fatty acid glycerides.

[0039] The toughening agent preparation method comprises the following steps:

[0040] Add acrylate polymer, acrylate-grafted styrene elastomer, antioxidant, and water into the reaction kettle, stir at 90°C for 4 hours, cool do...

Embodiment 3

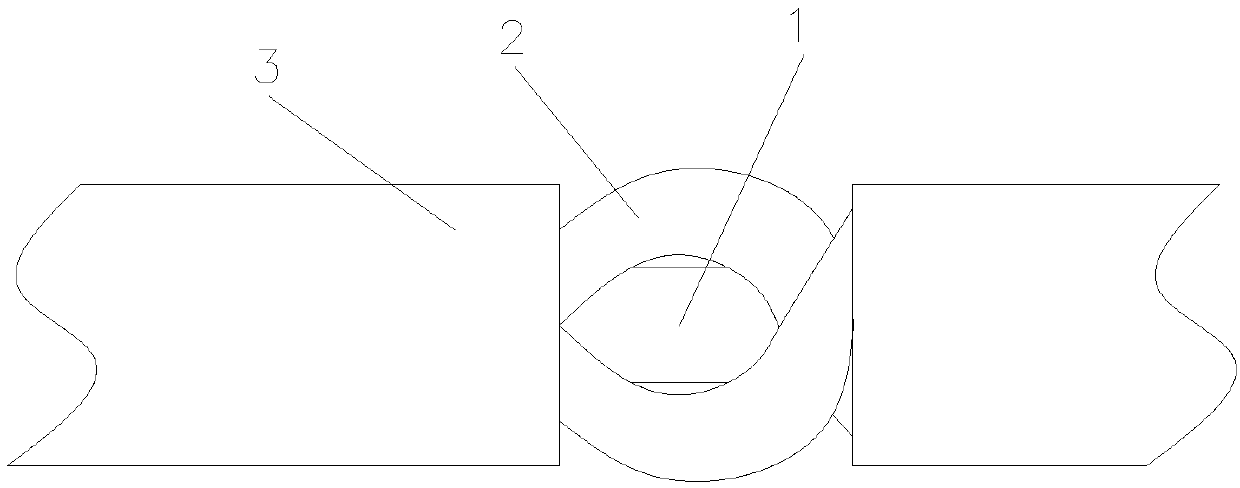

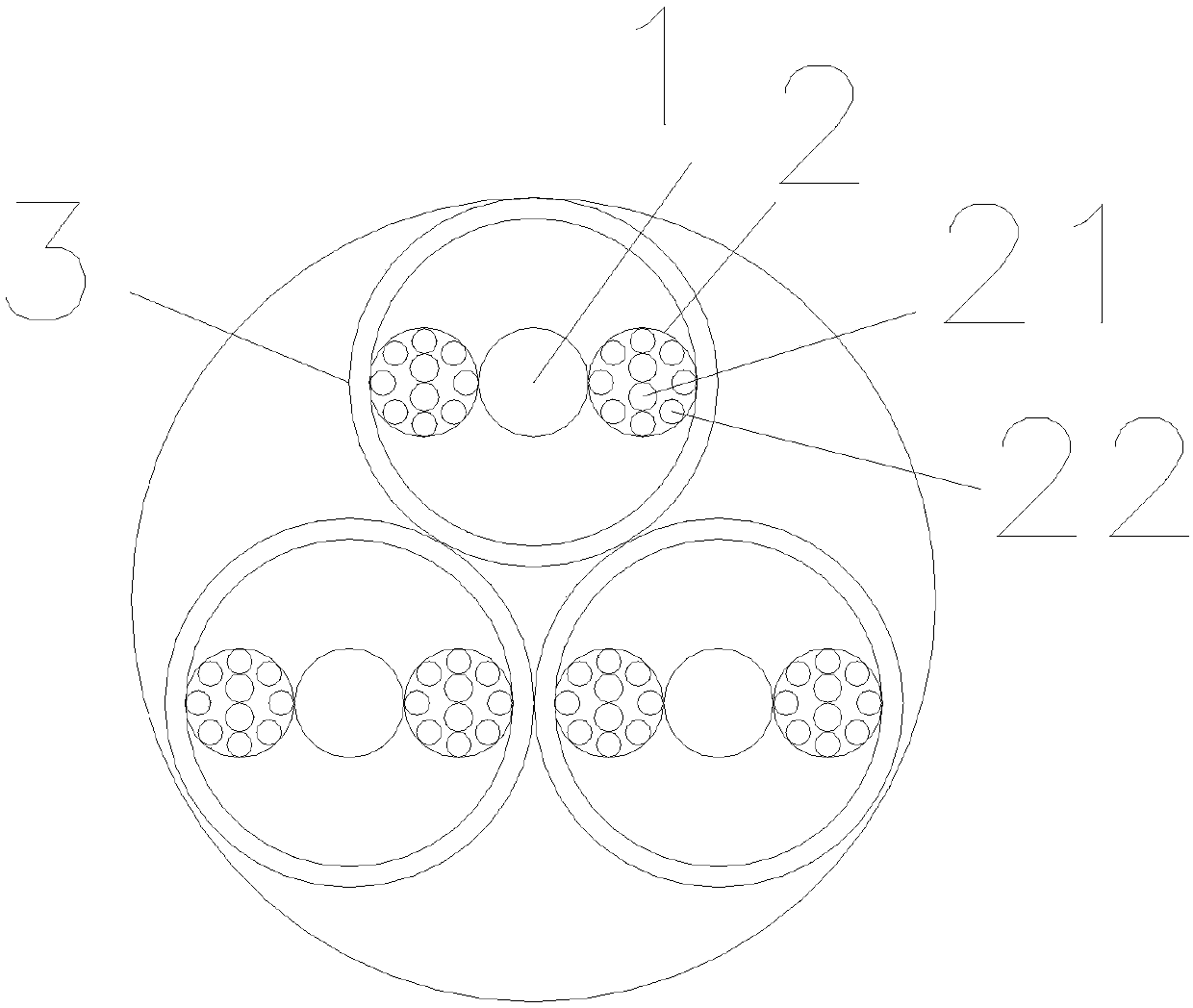

[0047] Embodiment 3: The main braided net after stretching is used on the aquaculture net. The cross-section profile of the aquaculture net is circular, with a diameter of 1 to 30 mm. It consists of three main braided ropes 1 and six secondary braided ropes 2. It is braided in a spiral shape, with two secondary braided ropes wrapped around each main braided rope.

[0048] Each secondary braided rope includes two nylon threads 21 and eight fiber filaments 22, and the fiber filaments are wound on the nylon threads.

[0049] The two secondary braided ropes wound on the main braided rope are wound in a knot every 20 centimeters, and put on the rubber sheath 3.

[0050]The diameter of the nylon thread in each secondary braided rope is 0.35mm-0.8mm, and the diameter of the fiber filament is 0.25mm-0.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com