Trench gate charge storage-type IGBT and manufacturing method thereof

A charge storage and charge storage layer technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as oscillation and EMI, and achieve the effects of reducing noise impact, improving switching speed, and reducing gate capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

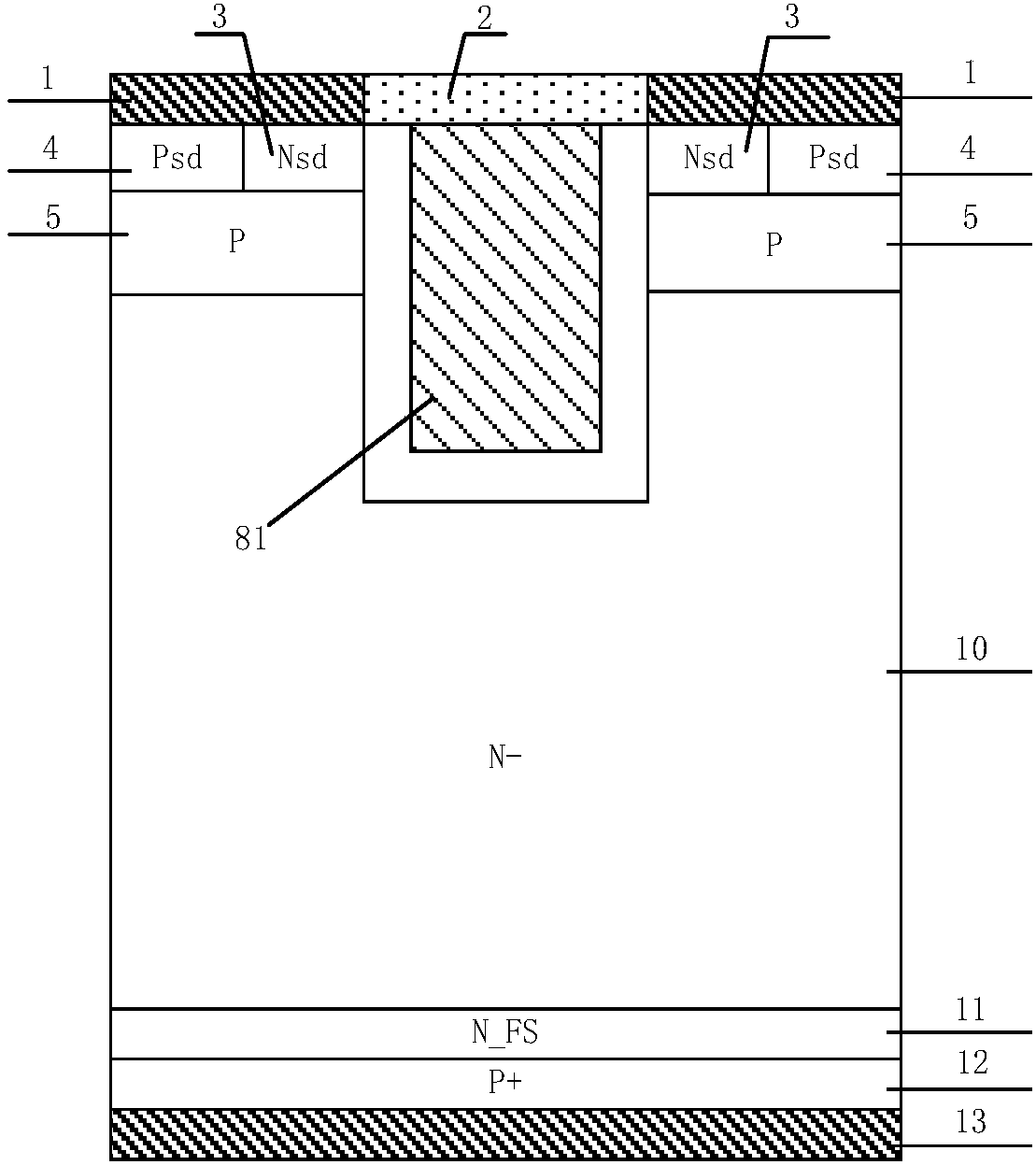

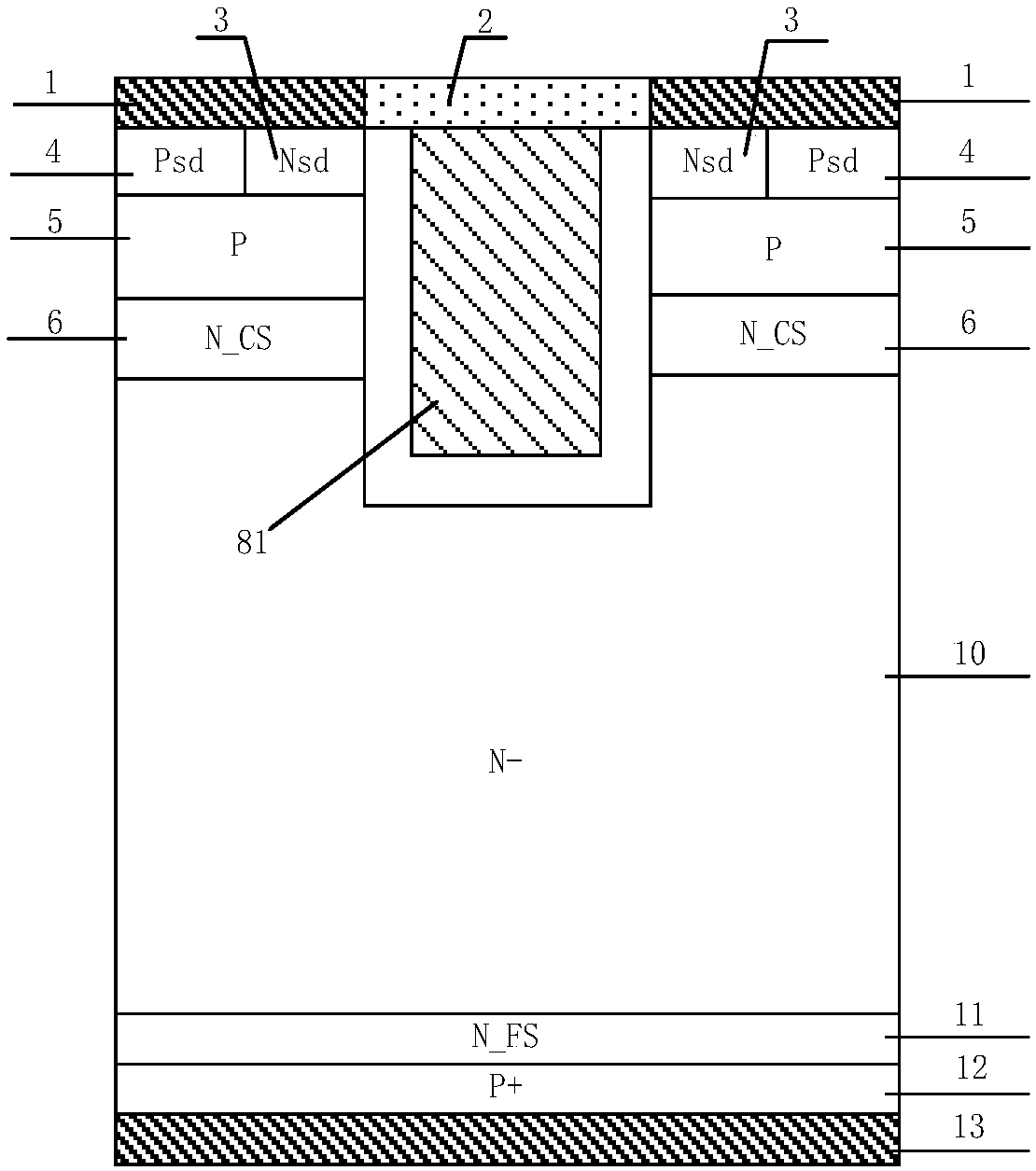

[0085] This embodiment provides a trench gate charge storage type IGBT, the cell structure of which is as follows image 3As shown, the collector metal 13, the P-type collector region 12, the N-type electric field stop layer 11, the N-type drift region 10 and the emitter metal 1 are stacked sequentially from bottom to top; it is characterized in that: the N-type drift The region 10 has an Nsd region 3, a Psd region 4, a P-type base region 5, an N-type charge storage layer 6 and a split trench gate structure; the Nsd region 3 and the Psd region 4 are in contact with each other and are located side by side under the emitter metal 1 and It is connected to the emitter metal 1; the P-type base region 5 is located below the Nsd region 3 and the Psd region 4 and connected to them, and the N-type charge storage layer 6 is located between the P-type base region 5 and the N-type drift region 10; The split trench gate structure includes: gate electrode 81, first gate dielectric layer 82,...

Embodiment 2

[0087] This embodiment provides a trench gate charge storage type IGBT, the cell structure of which is as follows Figure 4 As shown, the difference from Example 1 is that a part of the lower right corner of the split electrode is etched away to form a ladder-shaped electrode structure, thereby increasing the thickness of the dielectric layer in the lower right corner of the split gate trench structure, thereby obtaining a higher impact breakdown voltage and better reliability.

Embodiment 3

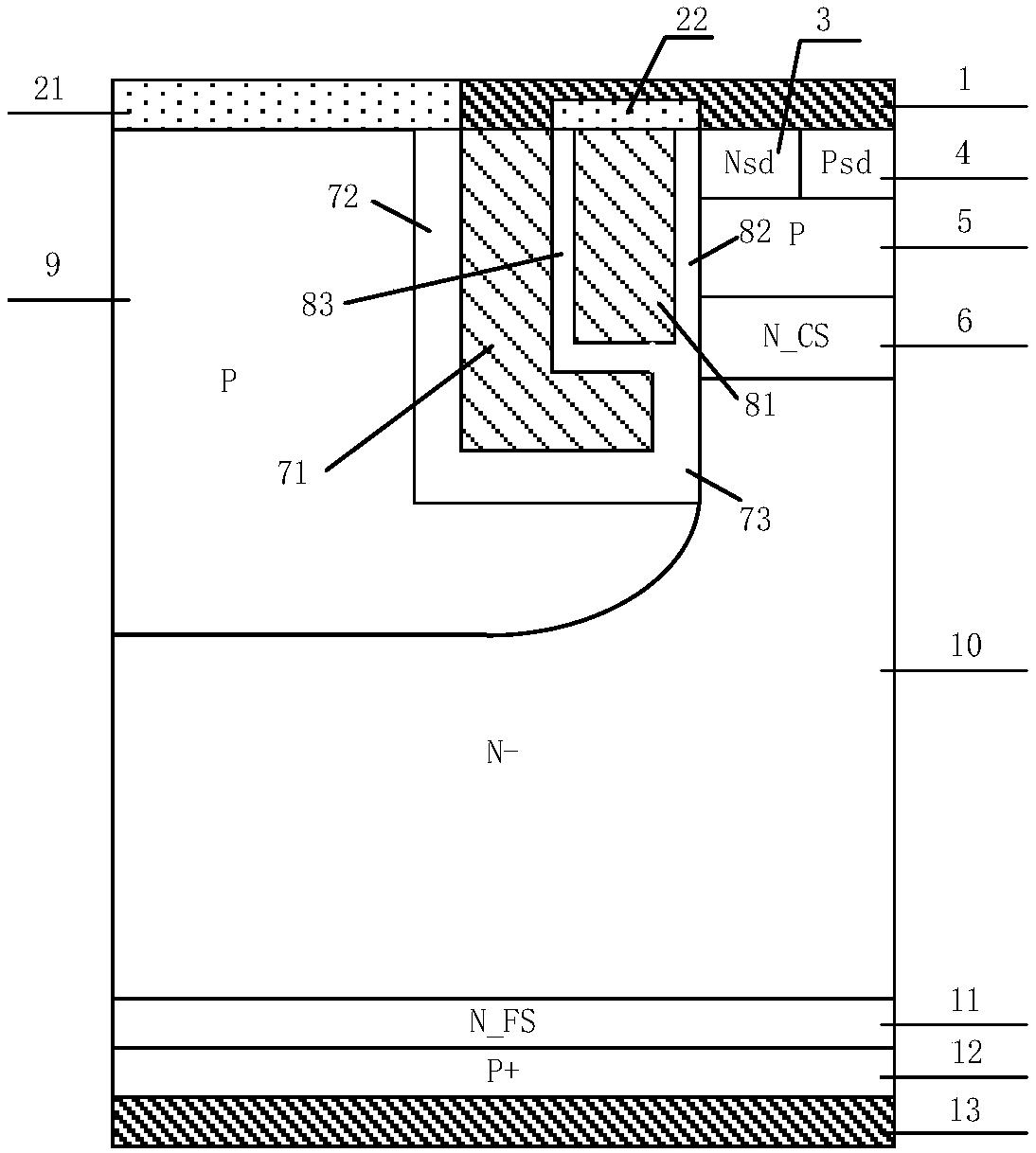

[0089] This embodiment provides a trench gate charge storage type IGBT, the cell structure of which is as follows Figure 5 As shown, the difference from Example 1 is that the split electrodes adopt N-type heavily doped, N-type lightly doped, and P-type doped polysilicon materials sequentially from top to bottom, and the polysilicon is depleted in the blocking state, which will reduce the Collector-emitter capacitance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com