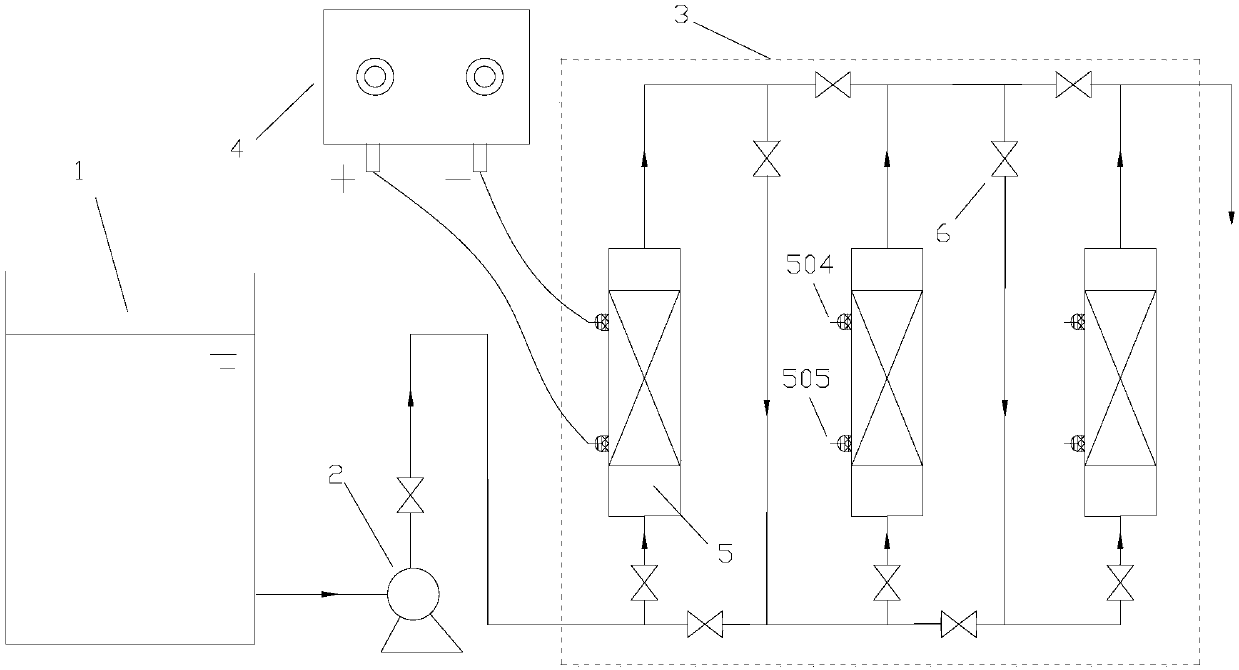

Electrochemical reinforced zero-valent iron waste water pretreatment system and method

A treatment system and technology of zero-valent iron, applied in electrochemical water/sewage treatment, chemical instruments and methods, magnetic/electric field water/sewage treatment, etc. It can improve the sludge activity and sedimentation, promote aggregation and sedimentation, and facilitate flexible operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The amount of pharmaceutical wastewater produced by a pharmaceutical company in Zhejiang Province is about 80m3 / h, the COD of wastewater is 808-1031mg / L, and the NH 4 + -N is 50~60mg / L, the company's raw sewage treatment system is anaerobic hydrolytic acidification +A 2 / O process, but the operation stability of the device is poor, and the effluent water quality fluctuates greatly; the analysis shows that the BOD of the raw wastewater is between 180 and 243 mg / L, and the B / C is less than 0.25, that is, the biodegradability of the wastewater is poor, and Wastewater contains a large amount of refractory substances and toxic and harmful substances, such as chlorinated hydrocarbons, chlorinated aromatics and organic chlorine fungicides, etc., resulting in low sludge activity and poor settleability. Currently, the process effluent COD is 123-230mg / L, BOD is 22-41mg / L, NH 4 + -N is 23~38mg / L, SS is 53~91mg / L, the company plans to upgrade the existing process to meet the ac...

Embodiment 2

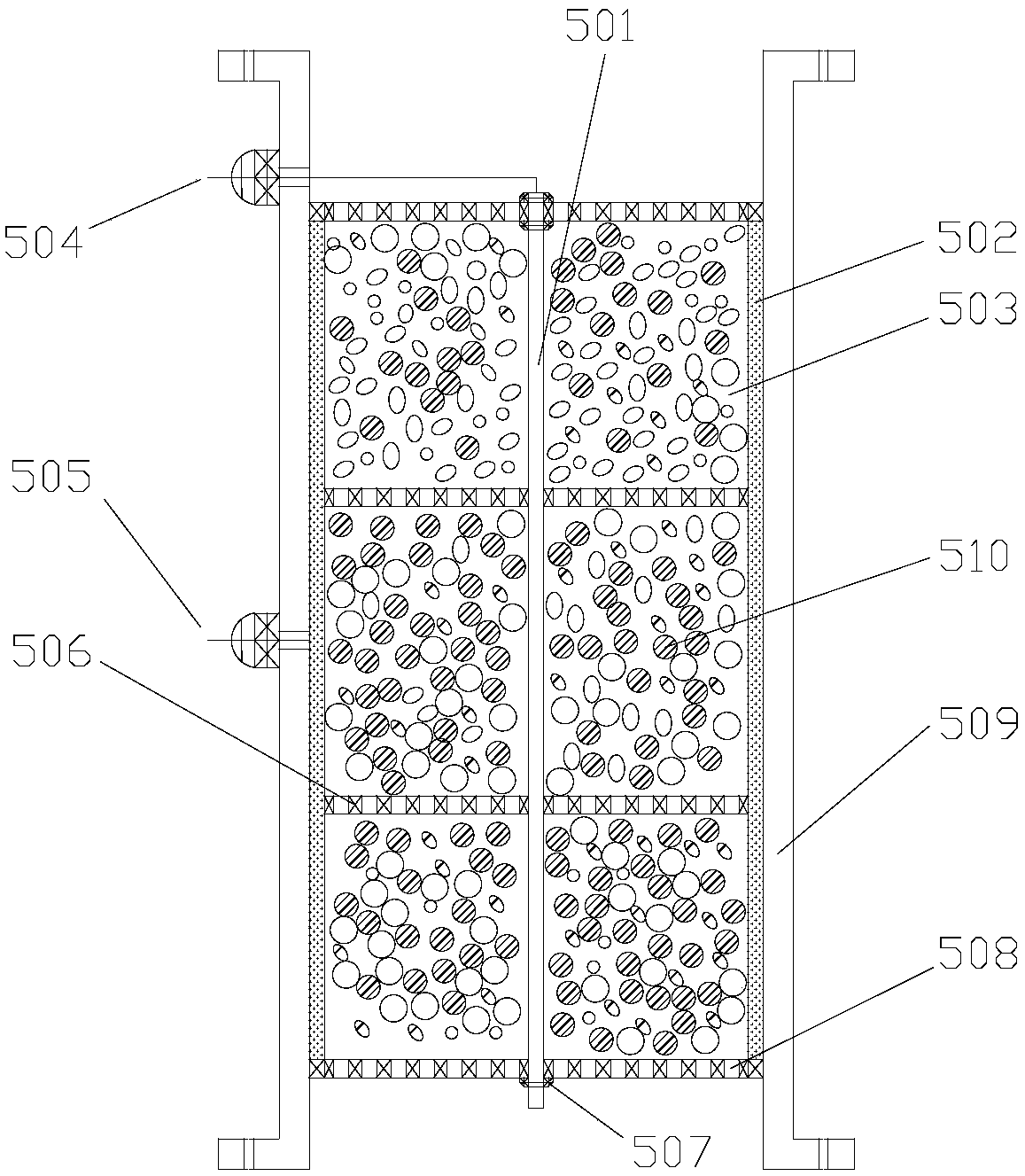

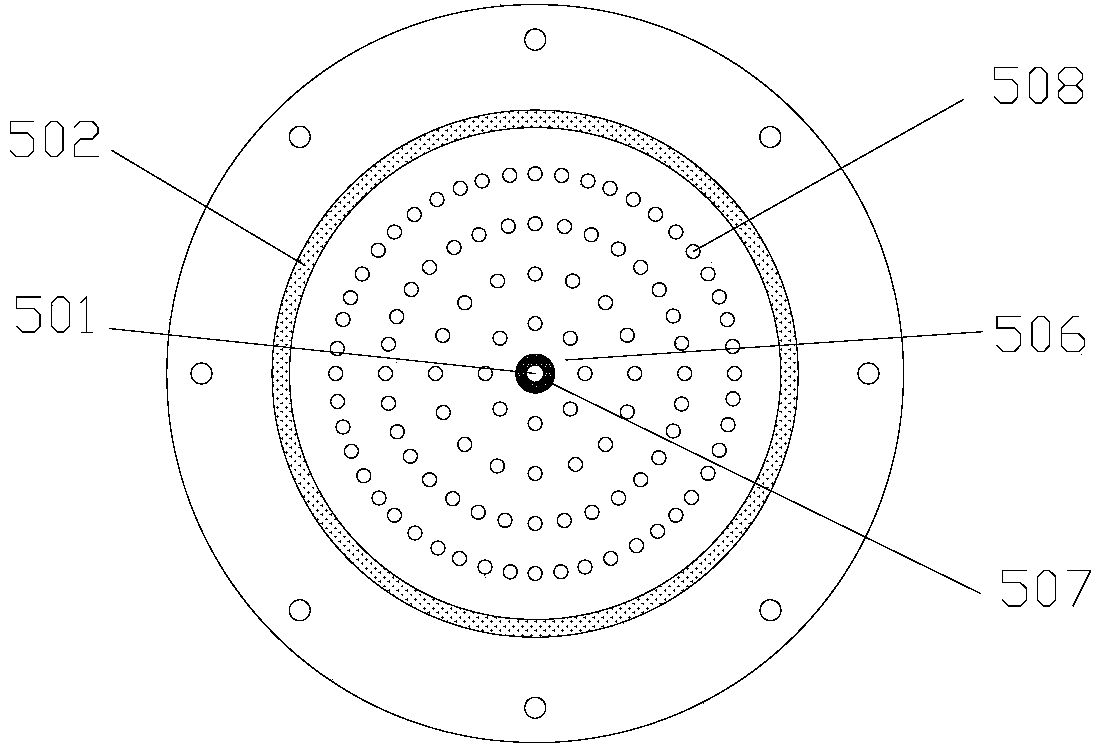

[0030] The wastewater volume of a coking plant in Inner Mongolia is about 200m 3 / h, at present, the anaerobic hydrolysis acidification + oxidation ditch treatment process is used for wastewater treatment, but because the wastewater contains a large amount of refractory and toxic and harmful substances such as phenols and benzene, the biodegradability of the wastewater is poor, and the process treatment is unstable , The effluent water quality fluctuates greatly, and the company plans to upgrade the process to improve system stability. Using the electrochemically enhanced zero-valent iron wastewater pretreatment system of the present invention to carry out a small-scale test on the coking plant wastewater, the treatment capacity of the small-scale test device is about 20L / h, wherein the columnar The distance between the graphite cathode 501 and the cylindrical titanium anode 502 is 30 cm, the particle size of the active zero-valent iron particles 510 is about 2.2 cm, the layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com