n,n,o-tridentate mg/li bimetallic catalyst and its preparation method and application

A bimetallic catalyst, a technology for catalyzing aldehydes, used in physical/chemical process catalysts, catalytic reactions, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of insufficient catalyst activity, complex catalyst structure, and long reaction time. and other problems, to achieve the effect of short catalytic reaction time, high yield and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

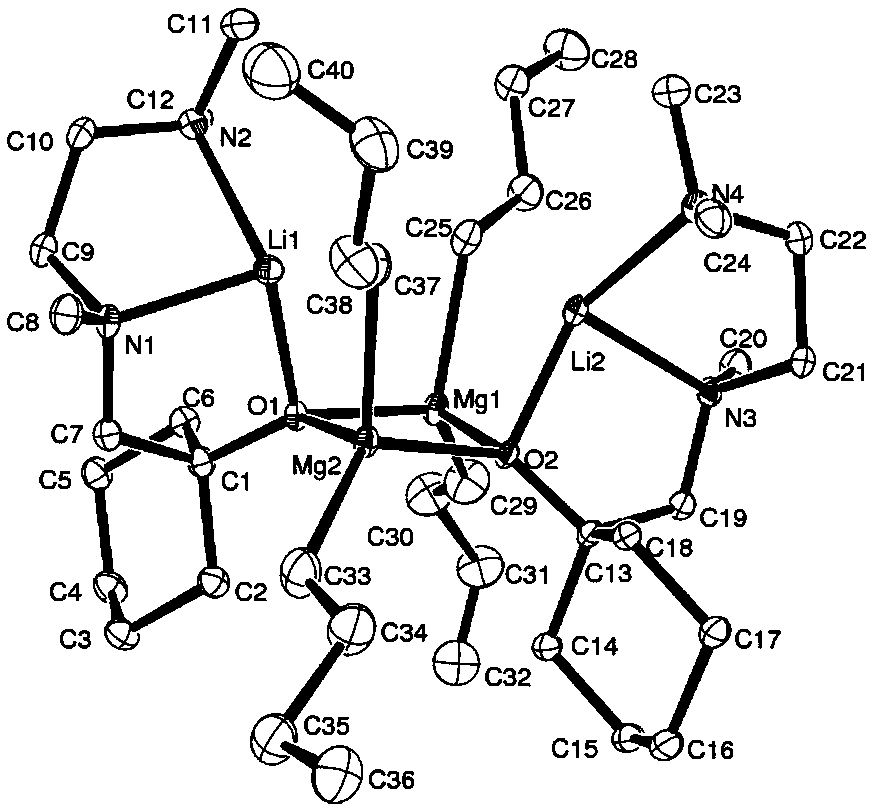

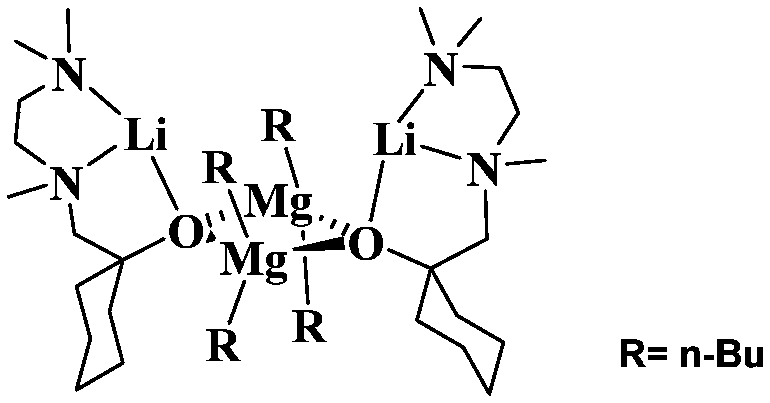

[0016] Embodiment 1N, N, the preparation of O-tridentate Mg / Li bimetallic catalyst

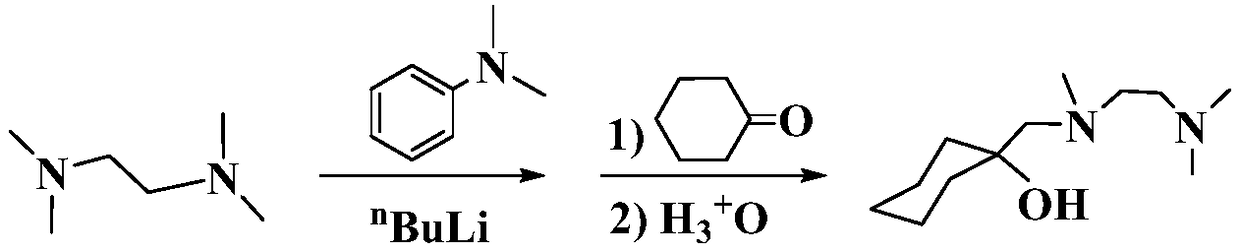

[0017] Slowly drop n-butyllithium (29.20 mL, 2.5 M, n-hexane solution) into the ether solution of TMEDA (11.02 g, 73 mmol) at 0°C, return to room temperature and react for 2 hours, then add cyclohexanone (7.54 mL, 73mmol) was dropped into the above-mentioned reaction solution to continue the reaction for 2 hours, then hydrolyzed under acidic conditions, and the aqueous phase obtained after liquid separation was neutralized to weak alkalinity with 5% aqueous sodium hydroxide solution, then extracted three times with anhydrous ether, organic The phase was dried with anhydrous magnesium sulfate and distilled under reduced pressure, and the colorless fraction at 78°C was collected to obtain the N,N,O-tridentate aminoalcohol ligand with a yield of 84%;

[0018] Under the protection of an inert gas, the N,N,O-tridentate aminoalcohol ligand (2.0mmol, 0.43g) was dissolved in 10mL of ether solvent, and...

Embodiment 2

[0022] (1) the preparation of catalyst is the same as embodiment 1

[0023] Catalytic reduction of benzaldehyde to benzyl alcohol (MPV): under nitrogen protection at room temperature, benzaldehyde (0.42g, 4.0mmol) and isopropanol (0.37mL, 4.8mmol) were added to N,N,O-tridentate In the Mg / Li bimetallic catalyst (1.06g, 0.2mmol), after reflux stirring reaction for 1 hour, then terminate the reaction with water, extract with ether, dry, and after rotary evaporation, separate by column chromatography (mobile phase is 7:3 n-hexane and ethyl acetate mixed solvent), benzyl alcohol after concentration. Yield 96%. 1 HNMR (300MHz, CDCl 3 ): δ(ppm)3.62(s,1H,OH),4.55(s,2H,CH 2 ),6.86-7.39(m,5H,C 6 h 5 ).

Embodiment 3

[0025] (1) the preparation of catalyst is the same as embodiment 1

[0026] (2) Catalytic reduction of acetophenone to 1-phenylethanol (MPV): under nitrogen protection at room temperature, acetophenone (0.48g, 4.0mmol) and isopropanol (0.37mL, 4.8mmol) were added to N , N, O-tridentate Mg / Li bimetallic catalyst (1.06g, 0.2mmol), after reflux and stirring for 1 hour, then stop the reaction with water, extract with ether, dry, and after rotary evaporation, separate by column chromatography (The mobile phase is a 7:3 mixed solvent of n-hexane and ethyl acetate), and after concentration, it becomes 1-phenylethanol with a yield of 93%. 1 H NMR (300MHz, CDCl 3 ): δ(ppm)1.48(d,3H,CH3),3.62(s,1H,OH),4.65(s,H,CH),7.13-7.45(m,5H,C 6 h 5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com