Ultraviolet-blocking type photoluminescence PDMS composite material and preparation method thereof

A composite material and photoluminescence technology, which is applied in the field of photoluminescence PDMS composite materials and their preparation, can solve the problems of shortening the service life of composite materials and shortening the service life of functional composite materials, and achieves long service life and excellent ultraviolet blocking performance. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of ultraviolet blocking type photoluminescence PDMS composite material, is made of the raw material of following parts by weight:

[0051] Vinyl-terminated polysiloxane (vinyl content: 0.01mol / 100g, weight average molecular weight: 62000g / mol) 100 parts;

[0052] 0.1 parts of hydrogen-terminated silicon nanocrystals;

[0053] 0.02 parts of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex catalyst;

[0054] 0.004 parts of 3-methyl-1-butyn-3-ol

[0055] 3 parts of hydrogen-containing silicone oil with a hydrogen content of 0.5% and a viscosity of 10 cSt at room temperature;

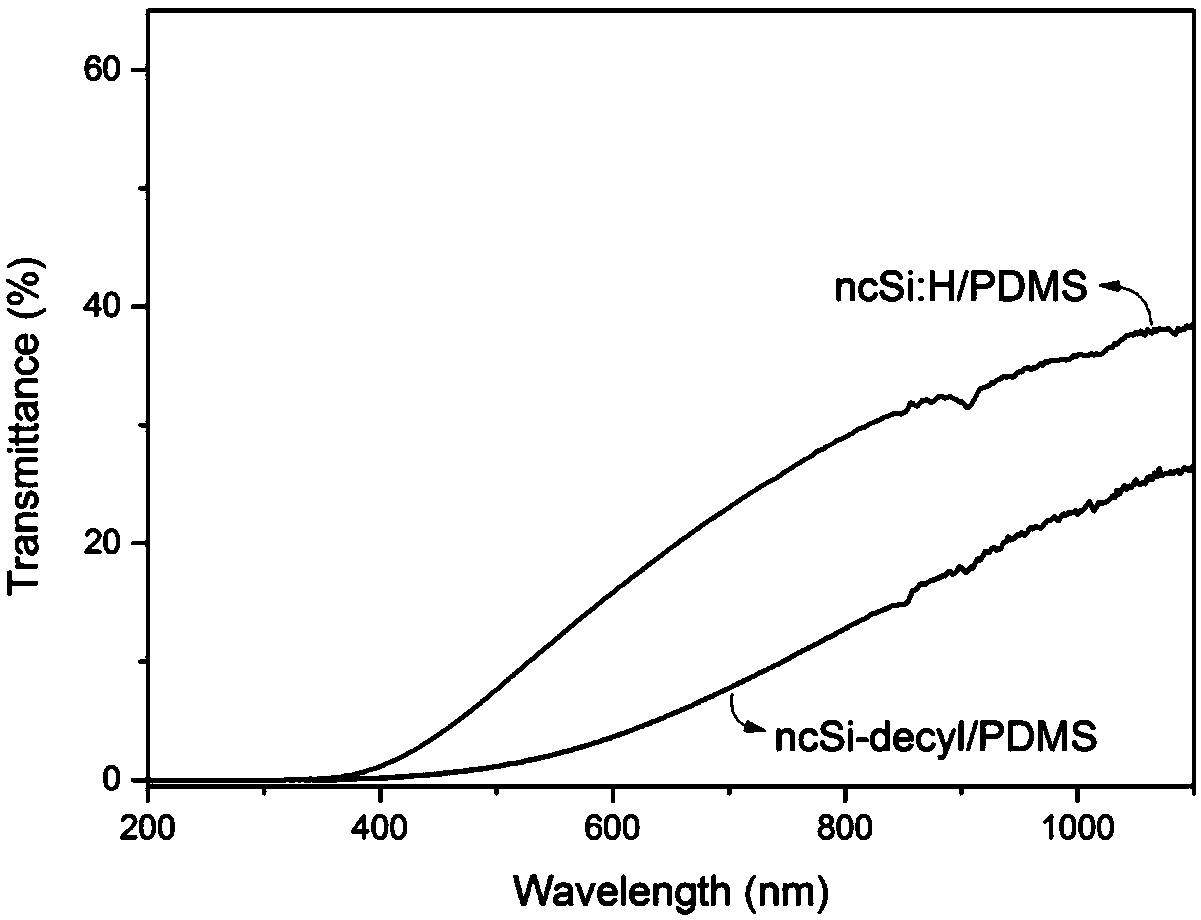

[0056] Mix the above-mentioned raw materials uniformly in a vacuum kneader, put them into a mold, remove air bubbles, and cure at 120°C for 0.1h to obtain a high-elastic (ncSi:H) / PDMS composite material with UV blocking, and replace the above silicon nanocrystals with After decyl-passivated silicon nanocrystals (ncSi-decyl), the same method was used to prepare (ncSi-decyl) / PDMS co...

Embodiment 2

[0058] A kind of ultraviolet blocking type photoluminescence PDMS composite material, is made of the raw material of following parts by weight:

[0059] Vinyl-terminated polysiloxane (vinyl content: 0.01mol / 100g, weight average molecular weight: 62000g / mol) 100 parts;

[0060] 0.1 part of silicon nanocrystal;

[0061] 10 parts of nano silica sol;

[0062] 0.02 parts of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex catalyst;

[0063] 0.004 parts of 3-methyl-1-butyn-3-ol

[0064] 3 parts of hydrogen-containing silicone oil with a hydrogen content of 0.5% and a viscosity of 10 cSt at room temperature;

[0065] Mix the above raw materials uniformly in a vacuum kneader, put them into a mold, remove air bubbles, and cure at 120 ° C for 0.1 h to obtain a highly elastic PDMS composite material with UV blocking, which can maintain high transparency similar to pure PDMS. It is detected that the ultraviolet protection factor (UPF) of the high elastic PDMS composite mater...

Embodiment 3

[0067] A kind of ultraviolet blocking type photoluminescence PDMS composite material, is made of the raw material of following parts by weight:

[0068] Vinyl-terminated polysiloxane (vinyl content: 0.01mol / 100g, weight average molecular weight: 62000g / mol) 100 parts;

[0069] 0.1 part of silicon nanocrystal;

[0070] 10 parts of MQ silicone resin with a viscosity of 10cSt at room temperature;

[0071] 0.02 parts of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex catalyst;

[0072] 0.004 parts of 3-methyl-1-butyn-3-ol

[0073] 3 parts of hydrogen-containing silicone oil with a hydrogen content of 0.5% and a viscosity of 10 cSt at room temperature;

[0074] Mix the above raw materials uniformly in a vacuum kneader, put them into a mold, remove air bubbles, and cure at 120 ° C for 0.1 h to obtain a highly elastic PDMS composite material with UV blocking, which can maintain high transparency similar to pure PDMS. It is detected that the ultraviolet protection facto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com