A self-layered gradient fluorine-silicon-based superhydrophobic coating and its preparation process

A super-hydrophobic coating and self-layering technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficult maintenance, high cross-linking and curing temperature of coatings, complicated preparation process, etc., and achieve simple and easy preparation process Good durability, good hardness and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

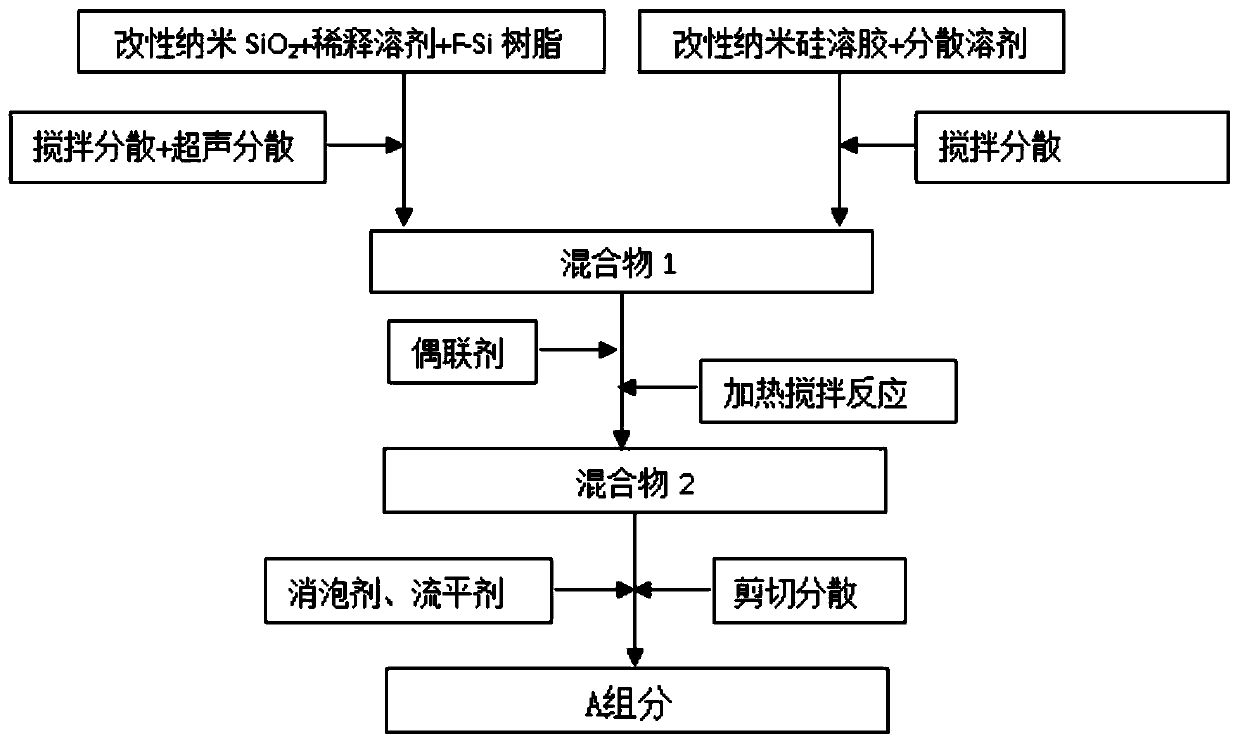

[0055] In order to obtain a better self-layered gradient fluorine-silicon-based superhydrophobic coating, the present application has optimized a method for preparing a self-layered gradient fluorine-silicon-based superhydrophobic coating, including the following steps:

[0056] (1) Nano SiO 2 Modification of powder: Add a certain amount of deionized water (w=5%) into absolute ethanol, mix well and add a certain amount of silane coupling agent or organosilicon compound, ultrasonically disperse for 3 minutes to 5 minutes, and the nano SiO 2 Add the powder into the solution, heat and stir, the temperature is 50°C-70°C, the reaction time is 6h-8h, aged at 80°C for 12-18h, ultrasonically cleaned with ethanol, centrifuged, repeated three times, and then dried at 80°C for 3h ~6h, prepared modified nano-SiO 2 Powder;

[0057] (2) Modification of nano-silica sol: add a certain amount of deionized water (w=5%) into absolute ethanol, adjust the pH value to 4±0.5 with acetic acid afte...

Embodiment 1

[0066] A self-layered gradient fluorosilicone-based superhydrophobic coating, including two components with the following mass percentages of A and B, and component A is composed of the following substances in weight percentages: 50% fluorosilicone resin, 30% diluting solvent, and dispersing solvent 10%, modified nano-SiO 2 Powder 3%, modified nano silica sol 6%, coupling agent 0.5%, defoamer 0.2%, leveling agent 0.3%. Component B: Aliphatic polyisocyanate. The mass ratio of A and B components is 25:1.

[0067] The dilution solvent is a mixture of butyl acetate, xylene and propylene glycol methyl ether acetate, and the weight ratio is 1:1:1. Butyl acetate, xylene, and propylene glycol methyl ether acetate have good solubility for fluorosilicone resins. However, due to the relatively fast volatilization rate of butyl acetate, xylene and propylene glycol methyl ether acetate can reduce the volatilization of diluent solvents. Speed, in order to adjust the volatilization rate a...

Embodiment 2

[0080] The present embodiment raw material is identical with the raw material of embodiment 1.

[0081] The preparation method of the self-layered gradient fluorine-silicon-based superhydrophobic coating of this embodiment comprises the following steps:

[0082] (1) Nano SiO 2 Modification of powder: Add a certain amount of deionized water (w=5%) into absolute ethanol, add KH550 after mixing, ultrasonically disperse for 3 minutes, and mix nano-SiO 2 The powder is added to the solution, heated and stirred, the temperature is 50°C, the reaction time is 6h, aged at 80°C for 12h, ultrasonically cleaned with ethanol, centrifuged, repeated three times, and then dried at 80°C for 3h to obtain modified nano-SiO 2 Powder;

[0083] (2) Modification of nano-silica sol: add a certain amount of deionized water (w=5%) in absolute ethanol, adjust the pH value to about 4 with acetic acid after mixing, add a certain amount of dodecafluoroheptyl Propyltrimethoxysilane, ultrasonically dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com