Organic wastewater treatment system

A technology for organic wastewater treatment and pretreatment, which is applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc. The effect of wastewater treatment efficiency, high treatment efficiency and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

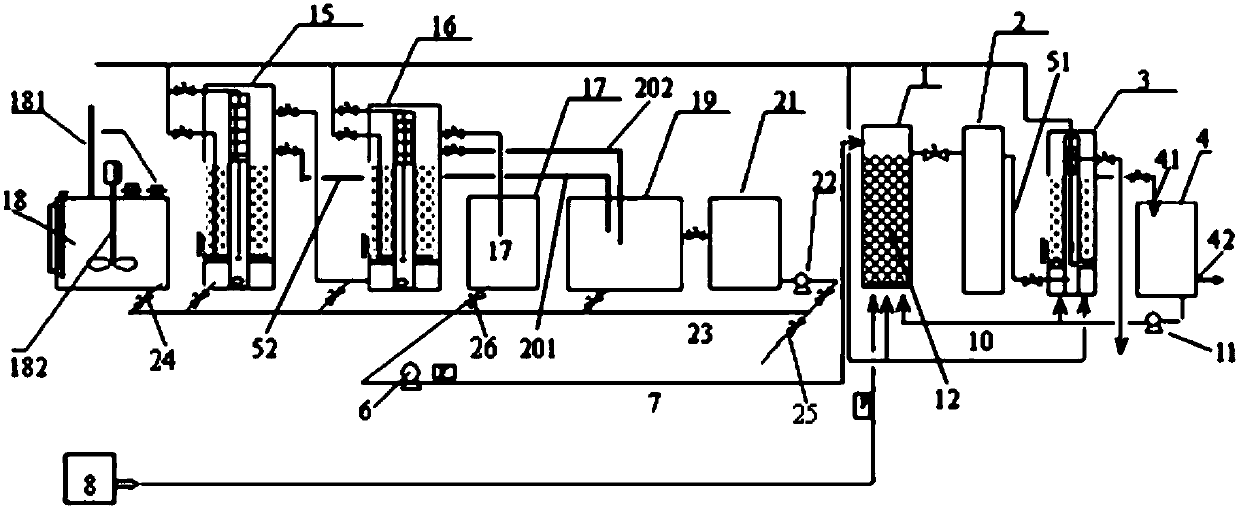

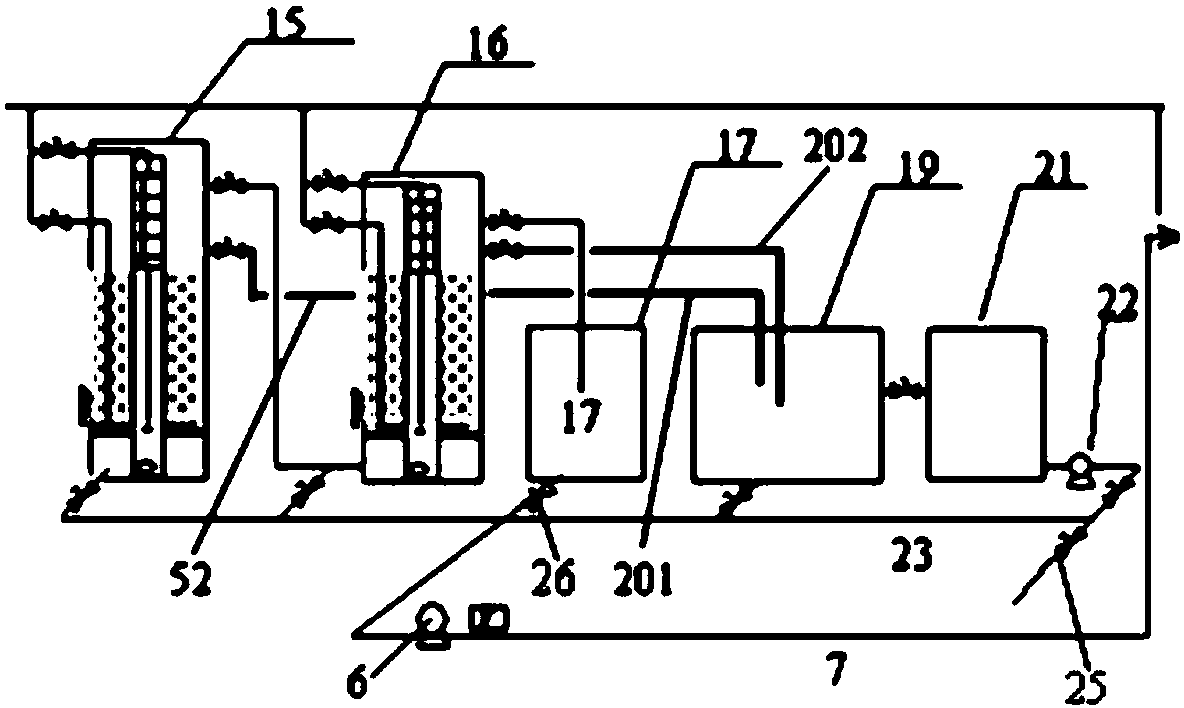

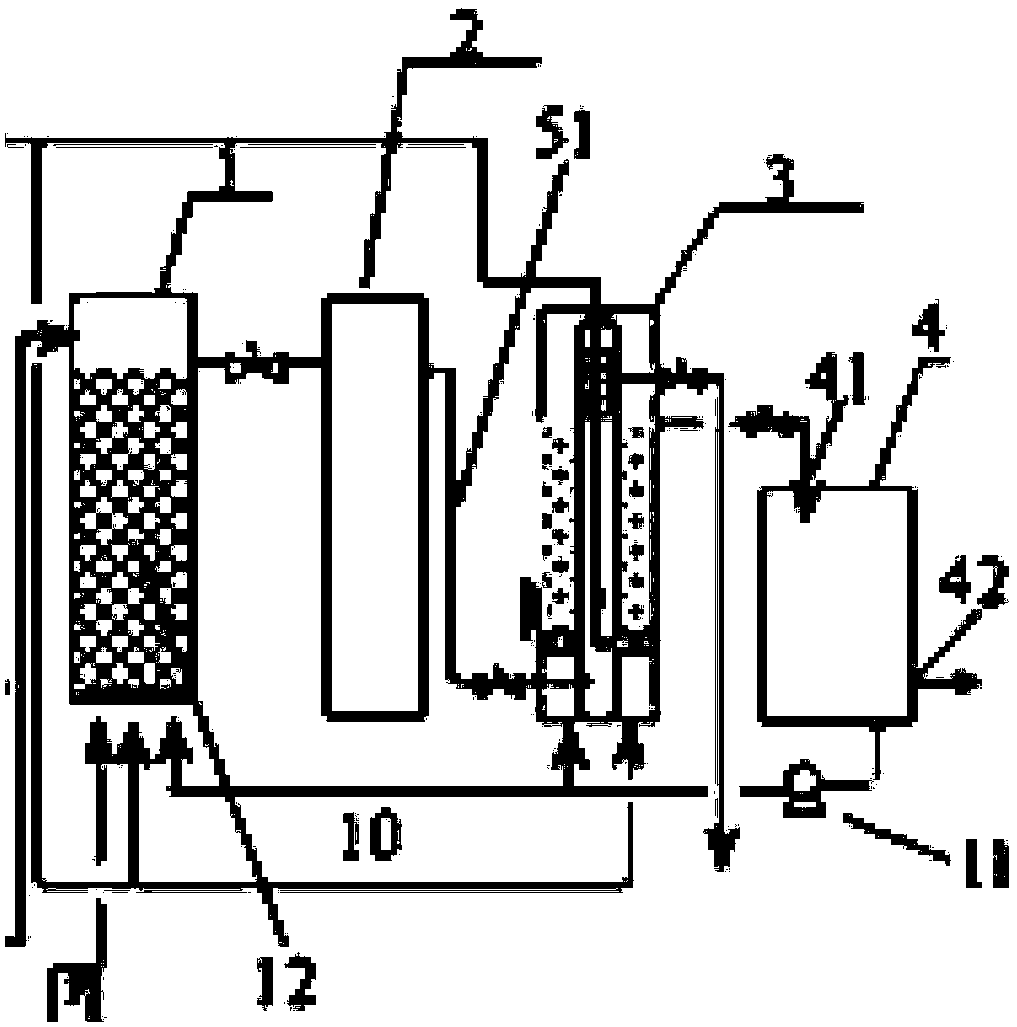

[0041] Embodiment 1~4: A kind of organic waste water treatment system, comprises catalytic oxidation tank 1, oxidation stabilization tank 2, post-biochemical BAF tank 3, clear water tank 4, dilution comprehensive tank 18, pretreatment primary BAF tank 15, pretreatment two Level BAF pool 16 and effluent pool 17, described dilution comprehensive tank 18, pretreatment primary BAF pool 15, pretreatment secondary BAF pool 16 and effluent pool 17 are connected through front section transmission pipeline 51 successively,

[0042] The catalytic oxidation pool 1, the oxidation stabilization pool 2, the post-biochemical BAF pool 3 and the clean water pool 4 are sequentially connected through the rear section transmission pipeline 52, and the outlet pool 17 and the catalytic oxidation pool 1 are connected to the catalytic oxidation pool 1 through the water inlet pipeline 7. inside pool 1,

[0043]An ozone generator 8 is connected to the inside of the catalytic oxidation tank 1 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com