Biological slow-release fertilizer for passion fruit

A slow-release fertilizer and passion fruit technology, which is applied in the field of passion fruit biological slow-release fertilizer, can solve problems such as affecting the growth of passion fruit, changing soil fertilizer rate, and lack of microorganisms, and achieves rich microbial flora, high nutrient content, and dissolution. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

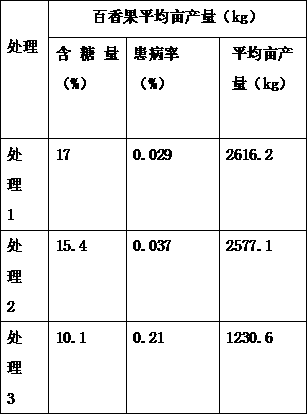

Image

Examples

Embodiment 1

[0035] Described passion fruit biological slow-release fertilizer comprises the raw material of following parts by weight:

[0036] 35 parts of urea; 30 parts of potassium polyphosphate; 45 parts of roast bone meal; 0.1 part of magnesium sulfate; 0.3 part of calcium chloride; 1 part of trace elements; 10 parts of fermented fertilizer; 2 parts of tea saponin; 8 parts of vegetable oil bran cake; 10 parts; 10 parts of bentonite.

[0037] The preparation method of described potassium polyphosphate comprises the following steps:

[0038] ① Put yellow phosphorus in a combustion furnace and burn it at 450°C to get P 2 o 5 gas;

[0039] ②Use a blower to blow P 2 o 5 The gas is pumped into the polymerization tower, and water is continuously sprinkled to make P 2 o 5 The gas dissolves in water, to the P in the solution 2 o 5 The weight concentration of reaches 70%, obtains solution;

[0040] 3. in the solution obtained, according to hydrogen sulfide gas: solution is 1:1000 we...

Embodiment 2

[0048] Described passion fruit biological slow-release fertilizer comprises the raw material of following parts by weight:

[0049] 45 parts of urea; 35 parts of potassium polyphosphate; 50 parts of roasted bone meal; 0.2 parts of magnesium sulfate; 0.4 parts of calcium chloride; 1 part of trace elements; 18 parts of fermented fertilizer; 4 parts of tea saponin; 12 parts of vegetable oil bran cake; 13 parts; bentonite 11 parts.

[0050] The preparation method of described potassium polyphosphate comprises the following steps:

[0051] ① Put yellow phosphorus in a combustion furnace and burn it at 550°C to get P 2 o 5 gas;

[0052] ②Use a blower to blow P 2 o 5 The gas is pumped into the polymerization tower, and water is continuously sprinkled to make P 2 o 5 The gas dissolves in water, to the P in the solution 2 o 5 The weight concentration of reaches 80%, obtains solution;

[0053] 3. in the solution that obtains, according to hydrogen sulfide gas: solution is 1:1...

Embodiment 3

[0061] Described passion fruit biological slow-release fertilizer comprises the raw material of following parts by weight:

[0062] 50 parts of urea; 38 parts of potassium polyphosphate; 55 parts of roast bone meal; 0.3 parts of magnesium sulfate; 0.5 parts of calcium chloride; 1.5 parts of trace elements; 25 parts of fermented fertilizer; 5 parts of tea saponin; 15 parts of vegetable oil bran cake; 15 parts; 15 parts of bentonite.

[0063] The preparation method of described potassium polyphosphate comprises the following steps:

[0064] ① Put yellow phosphorus in a combustion furnace and burn it at 600°C to get P 2 o 5 gas;

[0065] ②Use a blower to blow P 2 o 5 The gas is pumped into the polymerization tower, and water is continuously sprinkled to make P 2 o 5 The gas dissolves in water, to the P in the solution 2 o 5 The weight concentration of reaches 90%, obtains solution;

[0066] 3. in the solution that obtains, according to hydrogen sulfide gas: solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com