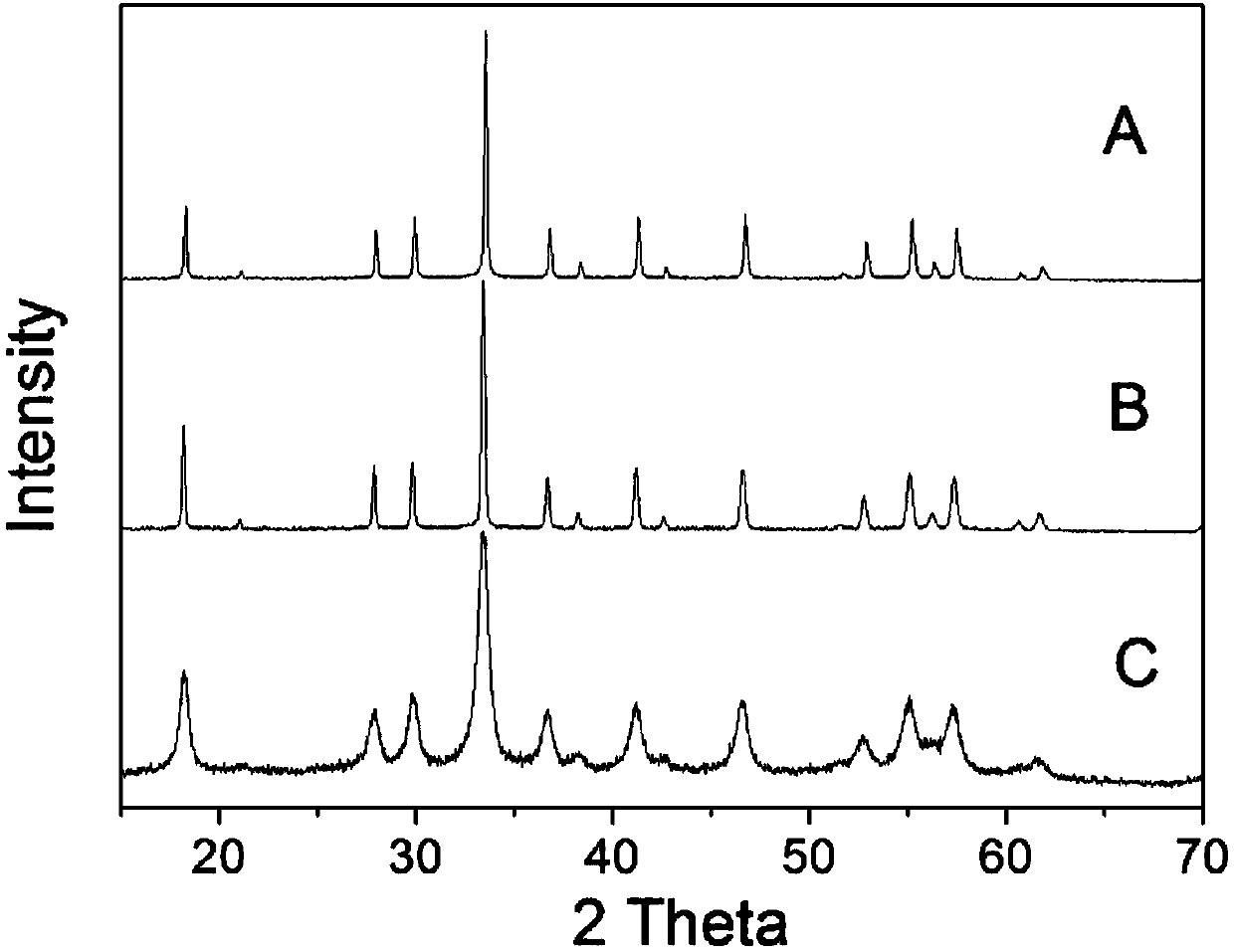

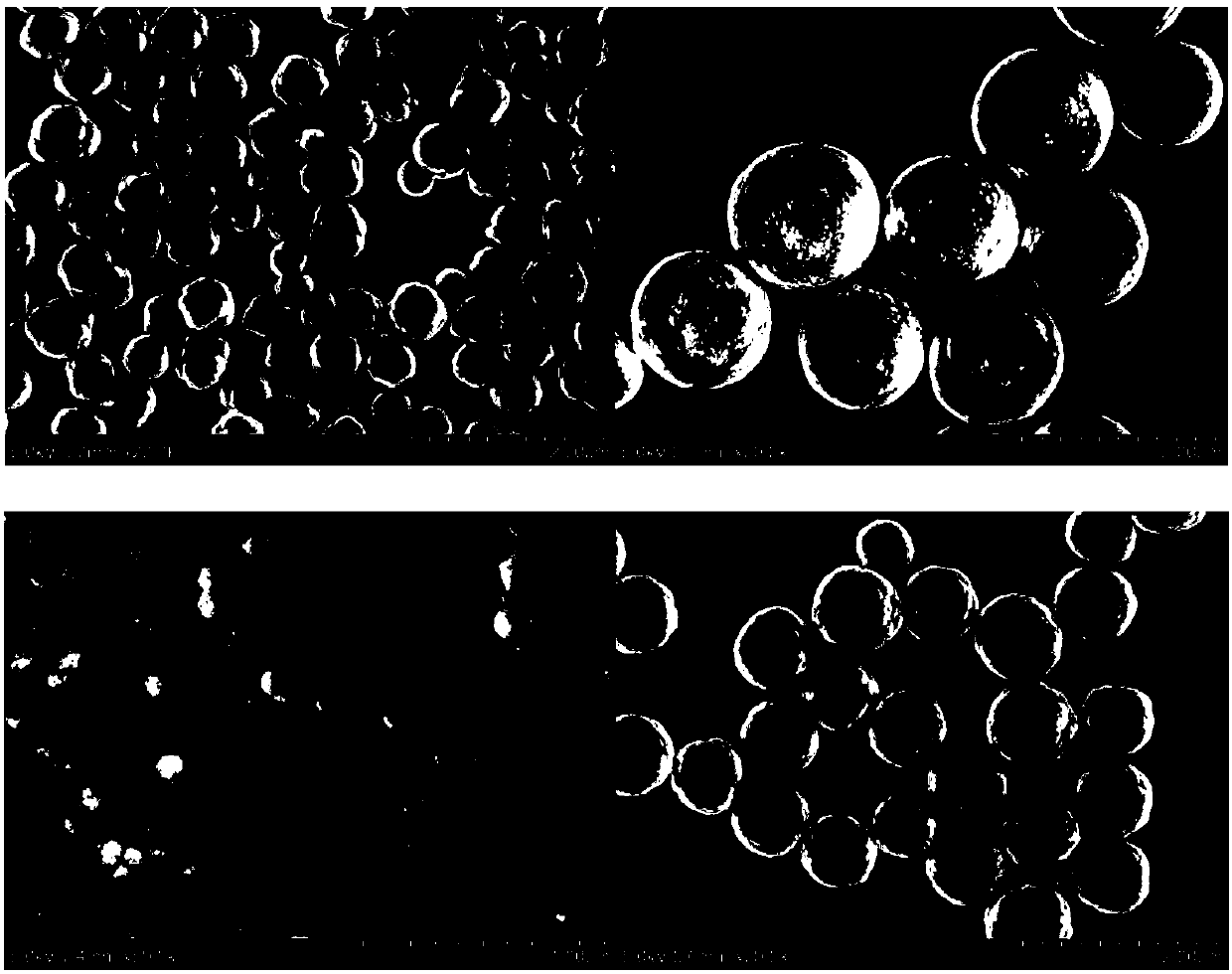

Preparation method of cerium-doped yttrium aluminum garnet spherical fluorescent powder

A technology of yttrium aluminum garnet and fluorescent powder, which is applied in the field of preparation of functional nanomaterials, can solve the problems of large particle size, uneven distribution of powder components, irregular agglomeration shapes, etc., and achieves good repeatability and wide and easy access to reagents , the effect of easily controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the cerium-doped yttrium aluminum garnet spherical phosphor body provided by the present invention specifically comprises the following steps:

[0059] (1) Configure the precursor reaction solution

[0060] Step 1-1: According to chemical formula Y 3-x Ce x al 5 o 12 , 03+ Concentration of 0.025 ~ 0.5mol / L mixed mother solution, NH 4 HCO 3 Soluble in ethanol-water mixed solvent, the volume ratio of ethanol to water is 0.2:1~1.5:1, to prepare NH 4 HCO 3 The concentration is 0.5~2.2mol / L precipitant solution;

[0061] Or step 1-2: according to chemical formula Y 3 al 5 o12 Metering ratio, that is, weigh the yttrium salt and the aluminum salt according to the molar ratio of Y and Al as 3:5, dissolve the yttrium salt and the aluminum salt in deionized water, and prepare the Al 3+ Concentration of 0.025 ~ 0.5mol / L mixed mother solution, NH 4 HCO 3 Soluble in ethanol-water mixed solvent, the volume ratio of ethanol to water is 0.2:1~1.5:1...

Embodiment 1

[0075] 0.0441mol Y (NO 3 ) 3 , 0.0009mol Ce(NO 3 ) 3 and 0.0765mol Al(NO 3 ) 3 Dissolved in 180mL deionized water, configured as Al 3+ Concentration is 0.425mol / L mixed salt solution, prepare 1500mL of NH with a concentration of 0.5mol / L with ethanol-water composite solvent with a volume ratio of ethanol and water of 3:2 4 HCO 3 The solution was stirred continuously during the titration. After the titration, it was aged at normal pressure and 20°C for 24 hours; the aged precipitation solution was centrifuged to obtain a milky white precipitate, and then the milky white precipitate was washed 3 times with deionized water to remove impurity ions. Wash twice with water and ethanol to remove water; put the washed white precipitate in an oven, and dry at normal pressure and 60°C for 24 hours to obtain Y 2.94 Ce 0.06 al 5 o 12 Precursor. weighing Y 2.94 Ce 0.06 al 5 o 12 0.40 g of the precursor was dispersed into 60 mL of ethylenediamine by stirring and ultrasonicati...

Embodiment 2

[0077] 0.0297mol YCl 3 , 0.0003mol Ce(NO 3 ) 3 and 0.05mol Al(NO 3 ) 3 Dissolved in 600mL deionized water, configured as Al 3+ Concentration is 0.083mol / L mixed salt solution, prepare 2000mL of NH with a concentration of 0.5mol / L with ethanol-water composite solvent with a volume ratio of ethanol and water of 1:1 4 HCO 3 The solution was stirred continuously during the titration. After the titration, age at normal pressure and 15°C for 8 hours; centrifuge the aged precipitate solution to obtain a milky white precipitate, then wash the precipitate with deionized water 3 times to remove impurity ions, and then use anhydrous Wash with ethanol twice to remove water; put the washed white precipitate in an oven, and dry at normal pressure and 60°C for 24 hours to obtain Y 2.97 Ce 0.03 al 5 o 12 Precursor. weighing Y 2.97 Ce 0.03 al 5 o 12 4.5g of the precursor was dispersed into a mixed solution of 72mL of ethylenediamine and 8mL of ethanol by stirring and ultrasonica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com