Ytterbium, sodium, calcium, lithium and niobium doped garnet crystal as well as preparation method and application thereof

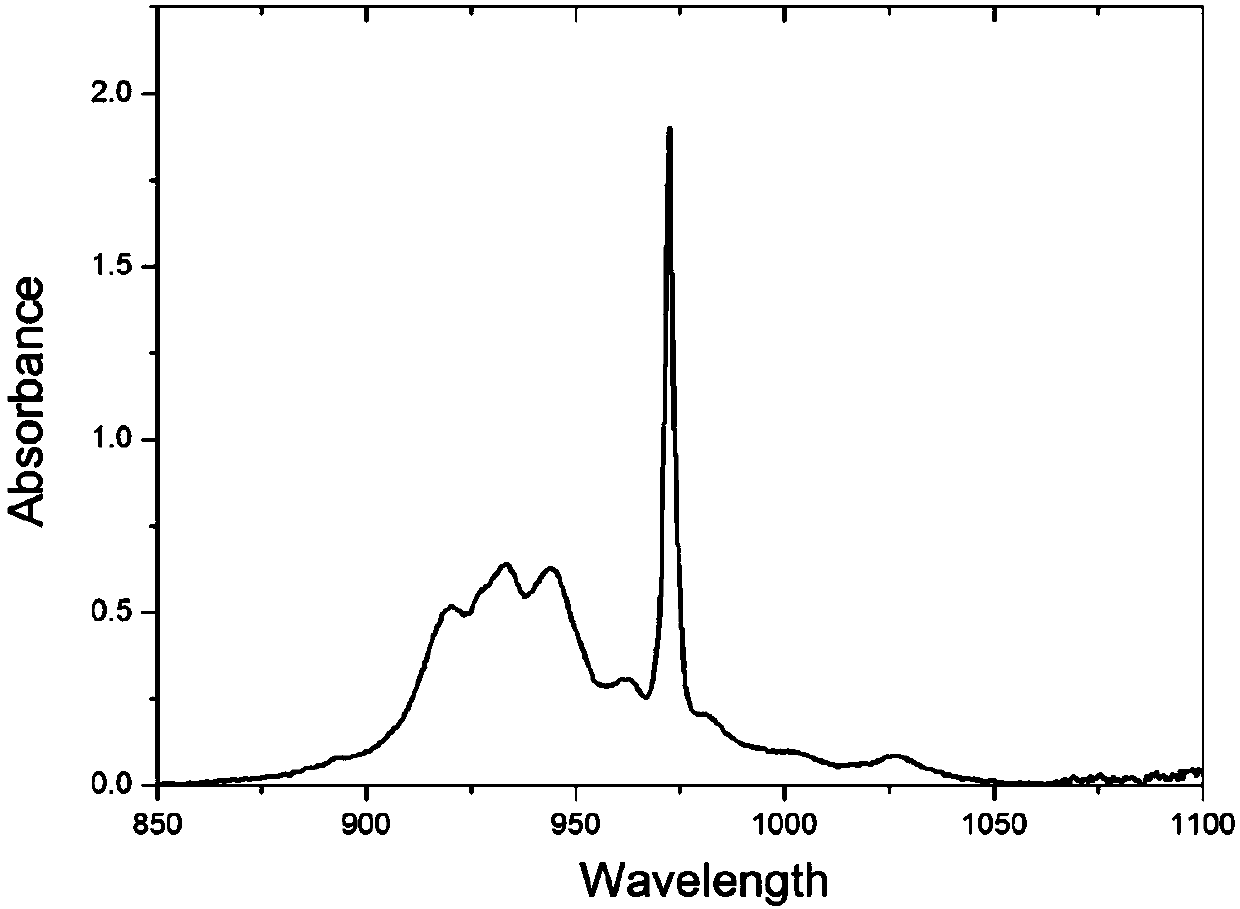

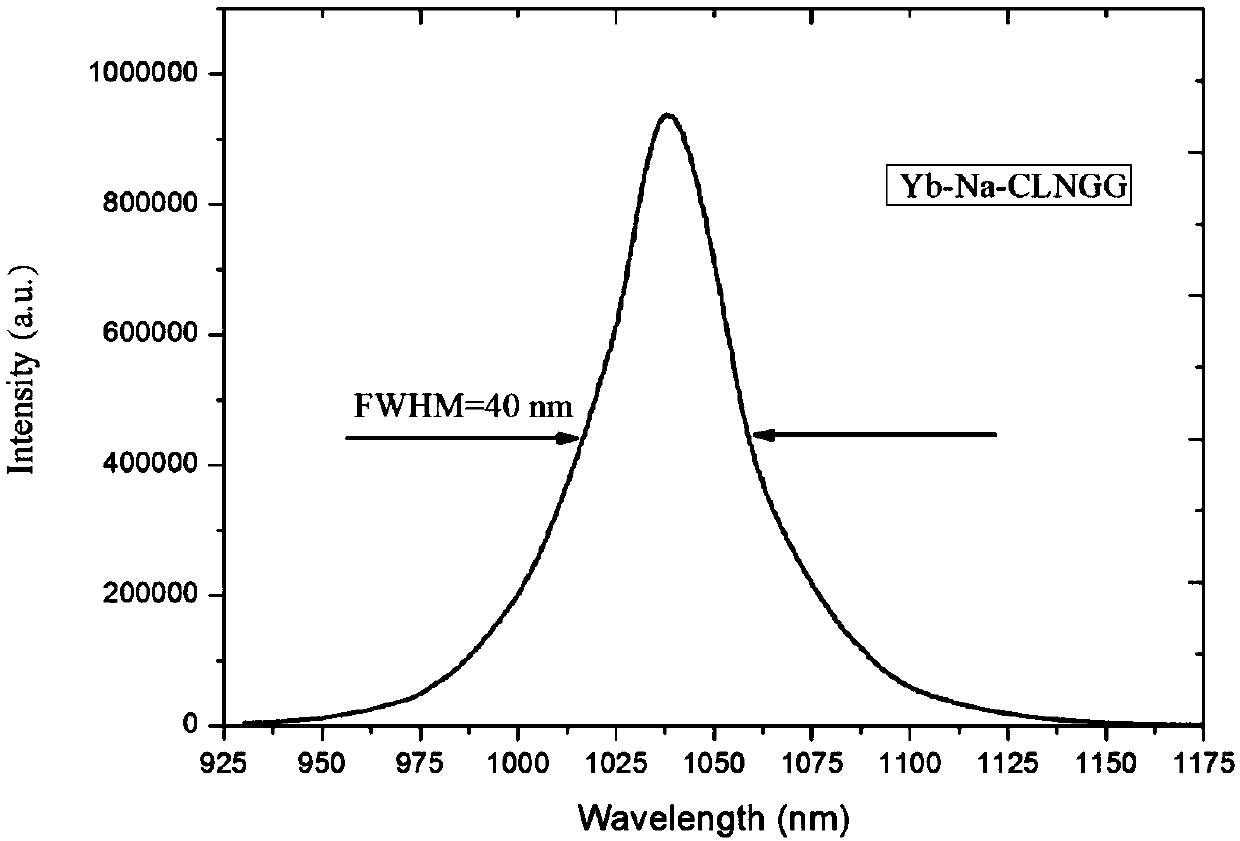

A technology of doping ytterbium sodium calcium lithium and garnet, applied in the field of laser crystal materials, can solve the problems of limited crystal application, narrow emission spectral bandwidth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

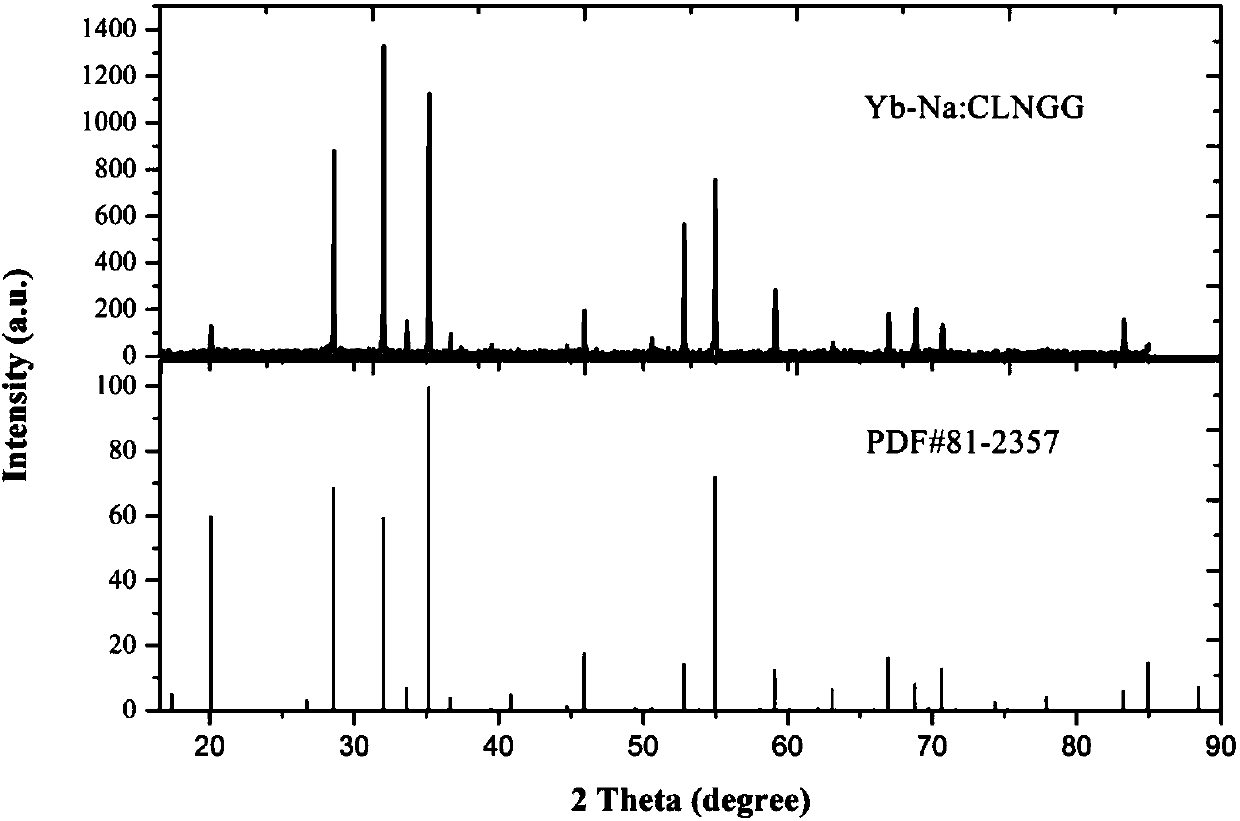

Embodiment 1

[0026] According to the following chemical formula:

[0027] X=0.15, y=0.275 according to the following chemical formula:

[0028] Weigh the compound CaCO 3 、Na 2 CO 3 , Nb 2 o 5 、Gd 2 o 3 , Yb 2 o 3 , Li 2 CO 3 After mixing, carry out solid phase reaction in muffle furnace at 1050°C for 24 hours; take it out and regrind into powder, mix and tablet, then carry out solid state reaction in muffle furnace at 1150°C for 30 hours and take it out Prepare polycrystalline material for later use.

[0029] The polycrystalline material is prepared by single crystal furnace pulling method. Put the polycrystalline material into the iridium gold crucible, in order to prevent the iridium gold crucible from being oxidized, first vacuumize and then rush into nitrogen as a protective gas. Set the intermediate frequency power of the heating program of the single crystal furnace to 4000w to completely melt the polycrystalline material. Afterwards, the seed crystal is used for pu...

Embodiment 2

[0032] It is basically the same as Example 1, except that x=0.24 and y=0.275. According to the chemical reaction formula:

[0033]

[0034] Weigh the compound CaCO 3 、Na 2 CO 3 , Nb 2 o 5 、Gd 2 o 3 , Yb 2 o 3 , Li 2 CO 3 After mixing, carry out solid phase reaction in muffle furnace at 1050°C for 24 hours; take it out and regrind into powder, mix and tablet, then carry out solid state reaction in muffle furnace at 1150°C for 30 hours and take it out Prepare polycrystalline material for later use.

[0035]The polycrystalline material is prepared by single crystal furnace pulling method. Put the polycrystalline material into the iridium gold crucible, in order to prevent the iridium gold crucible from being oxidized, first vacuumize and then rush into nitrogen as a protective gas. Set the intermediate frequency power of the heating program of the single crystal furnace to 4000w to completely melt the polycrystalline material. Afterwards, the seed crystal is used...

Embodiment 3

[0038] It is basically the same as Embodiment 1, except that x=0.3 and y=0.275. According to the chemical reaction formula:

[0039]

[0040] Weigh the compound CaCO 3 、Na 2 CO 3 , Nb 2 o 5 、Gd 2 o 3 , Yb 2 o 3 , Li 2 CO 3 After mixing, carry out solid phase reaction in muffle furnace at 1050°C for 24 hours; take it out and regrind into powder, mix and tablet, then carry out solid state reaction in muffle furnace at 1150°C for 30 hours and take it out Prepare polycrystalline material for later use.

[0041] The polycrystalline material is prepared by single crystal furnace pulling method. Put the polycrystalline material into the iridium gold crucible, in order to prevent the iridium gold crucible from being oxidized, first vacuumize and then rush into nitrogen as a protective gas. Set the intermediate frequency power of the heating program of the single crystal furnace to 4000w to completely melt the polycrystalline material. Afterwards, the seed crystal is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com