Resistive pressure sensor and preparation method thereof

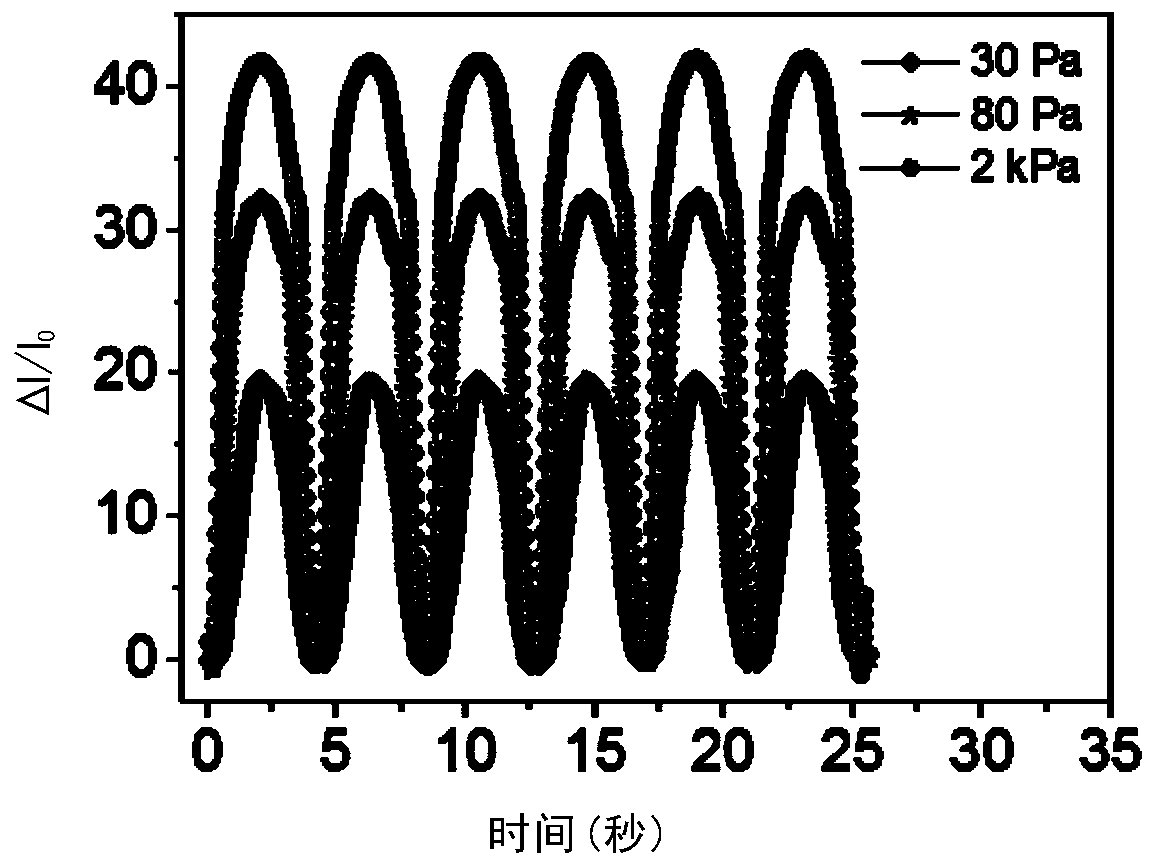

A resistive pressure and sensor technology, applied in the direction of sensors, instruments, measuring force, etc., can solve the problems of large volume, rough pulse detection results, inability to realize real-time monitoring and early warning, etc., and achieve the effect of wide sensing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

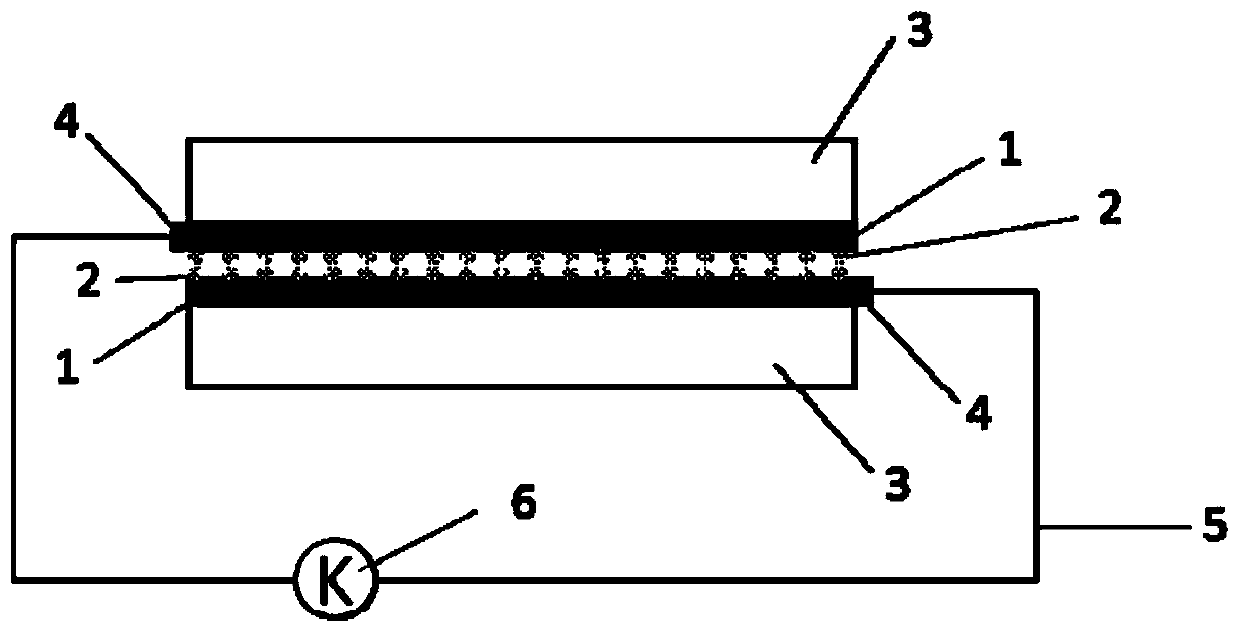

Method used

Image

Examples

Embodiment 1

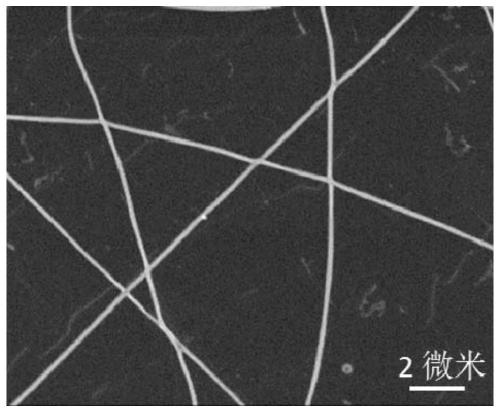

[0040] Put a copper foil with a thickness of 25 μm and a clean surface in a casing with a magnetic control device, then place the casing in a tube furnace, and raise the temperature of the furnace body to 1000 ° C under a hydrogen atmosphere with a flow rate of 300 sccm. The pressure of the system is 350 Pa, keep it for 30 minutes; keep the temperature of the furnace body at 1000°C, feed the hydrogen gas with the flow rate of 200 sccm and the methane gas with the flow rate of 1 sccm, keep it for 1 hour; single-layer graphene film.

[0041] The graphene film grown on the back side of the copper foil substrate was etched with 90W air plasma on the back side of the copper foil substrate for 5 minutes, and only the graphene film on the front side of the copper foil substrate remained. Put the copper foil with the graphene side facing upwards, place the electrospinning anode nozzle 25 cm above the copper foil / graphene, and the raw material for spinning is dimethyl formamide of PAN ...

Embodiment 2

[0051] Place the copper foil with a thickness of 25 μm and a clean surface in a casing with a magnetic control device, then place the casing in a tube furnace, and raise the temperature of the furnace body to 1000 ° C under a hydrogen atmosphere with a flow rate of 100 sccm. The pressure of the system is 120Pa, keep it for 30 minutes; keep the temperature of the furnace body at 1020°C, feed in hydrogen gas with a flow rate of 100 sccm and methane gas with a flow rate of 5 sccm, keep it for 30 minutes; the temperature drops rapidly to room temperature, ends the growth of graphene, and forms copper A single-layer graphene film full of layers on the foil.

[0052]The graphene film grown on the back of the copper foil substrate was etched with 90W air plasma on the back of the copper foil substrate for 3 minutes, and only the graphene film on the front of the copper foil substrate remained. Copper foil has graphene face up, the anode nozzle of electrospinning is placed 25 centimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com