Method for making inorganic synthetic paper

A manufacturing method and technology for synthetic paper, applied in the field of paper manufacturing, can solve the problems of large difference in transverse and longitudinal tensile strength, uneven light shielding, poor surface smoothness, etc., achieve uniform density and shielding rate, promote industrial upgrading, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

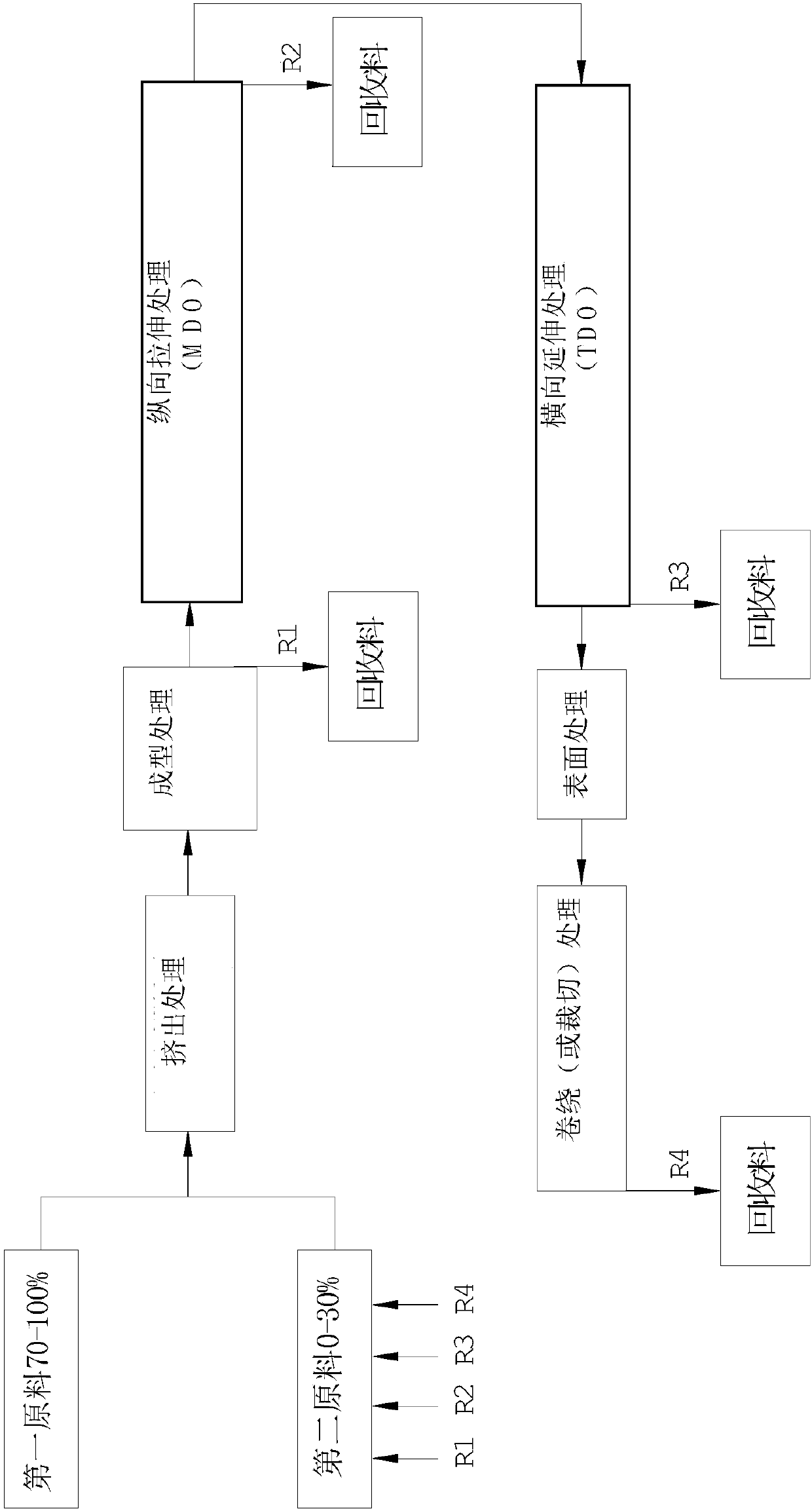

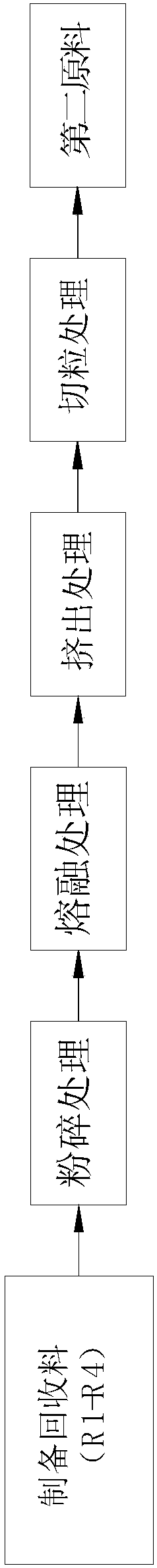

Method used

Image

Examples

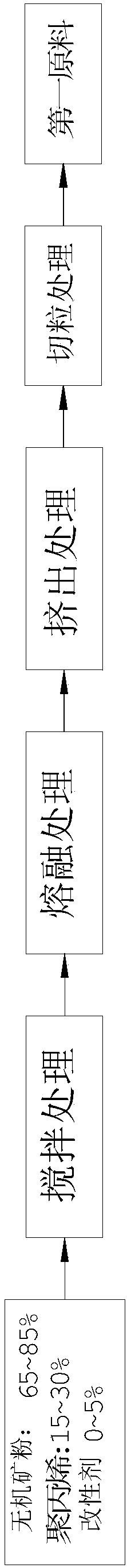

Embodiment 1

[0052] This embodiment accounts for 65% calcium carbonate by weight, 30% polypropylene (PP) (flow index (MFI) is between 2.5~3g / 10min, and tensile strength is more than 300kg / c㎡ (or 4500psi) homogeneous Monomer), 2.5% isopropyl triisostearyl titanate coupling agent (coupling agent), 1.5% ethoxy lauramide antistatic agent and 1% monoglyceride stearate lubricant as raw materials, after The large-scale continuous high-speed mixer continuously mixes and stirs, and then heats the raw materials to a temperature of 120-170°C to melt the raw materials, and then continues to heat the melted raw materials to 180-190°C to make the raw materials reach a uniform fusion state, and then mix the raw materials The first raw material obtained by extruding and pelletizing by a high-speed shearing machine. Next, feed the first raw material into the extruder for heating and melting at 200-250°C, then use a slit former (T-die) to form a soft thick sheet with a single-layer or three-layer structure,...

Embodiment 2

[0054] This embodiment accounts for 75% calcium carbonate by weight, 20% polypropylene (PP) (flow index (MFI) is between 2.5~3g / 10min, and tensile strength is more than 300kg / c㎡ (or 4500psi) homogeneous Monomer), 2.5% isopropyl triisostearyl titanate coupling agent (coupling agent), 1.5% ethoxylated lauryl amide antistatic agent and 1% monoglyceride stearate lubricant raw materials, through and The physical property test data of the inorganic synthetic paper with a thickness of 35 microns (μm) and 70 microns (μm) obtained by the same method as in Example 1 are shown in Table 1:

[0055] According to Table 1, Example 1 and Example 2, the inorganic synthetic paper has uniform thickness, density and shading rate, high whiteness index and gloss, low difference in transverse and longitudinal tensile strength, and transverse and longitudinal fracture. Uniform dot elongation, low coefficient of friction (smooth surface) and other advantages of excellent physical strength; therefore, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com