Method for high selectively preparing aldehyde by using olefin

A high-selectivity, olefin technology, applied in the fields of carbon monoxide reaction preparation, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem that catalyst activity and stability need to be improved, supporting ionic liquid Reduce the activity of phase catalysts, complex catalyst preparation process, etc., to achieve significant stereo effect, improve regioselectivity, and good stereoselectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

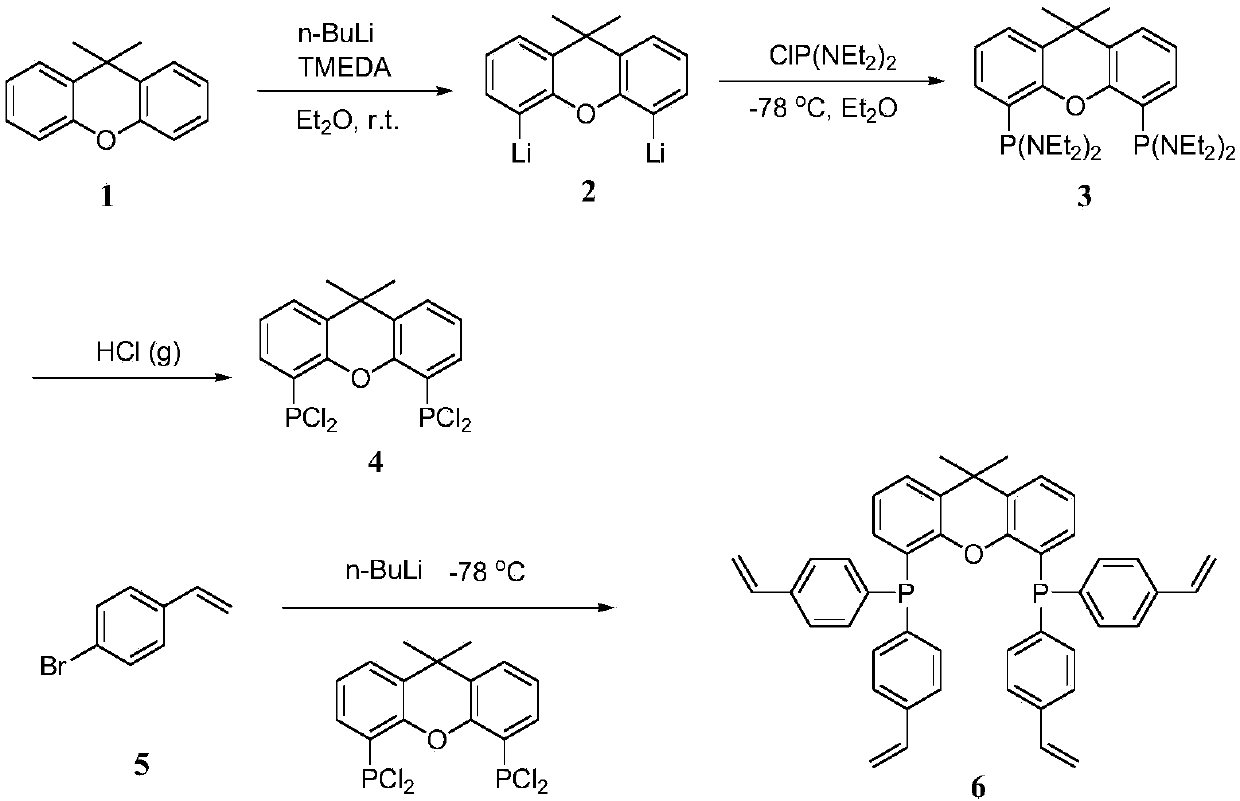

Embodiment 1

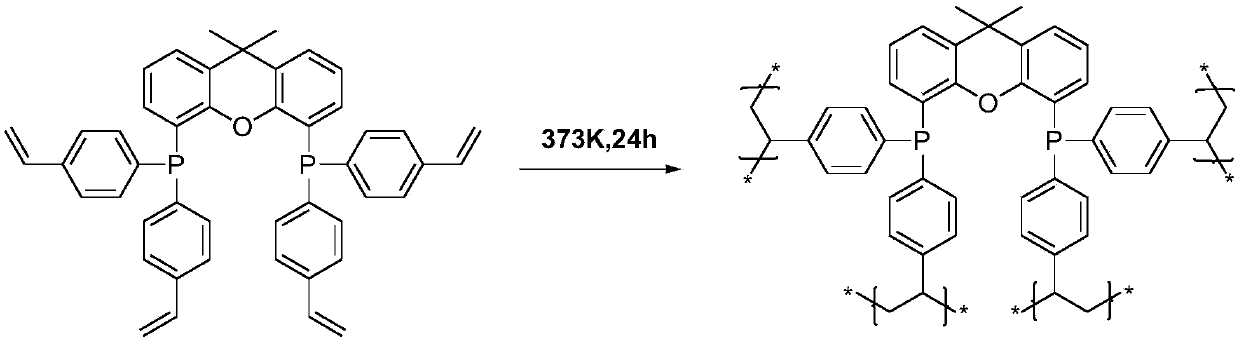

[0050] Preparation of the diphosphine ligand Vinyl Xantphos: The synthesis of the 4v-Xantphos ligand adopts a one-pot method (the route is as attached figure 1 shown). Since 9,9-dimethylxanthene (with figure 1 Compound No. 1) has heteroatom O at the 4- and 5-position β positions, so it is easier to undergo deprotonated lithiation to generate dilithium reagent 2. Compound 3 can be generated by reacting 2 with bis(diethylamino)chlorophosphine. Concentrated sulfuric acid reacts with concentrated hydrochloric acid to prepare HCl (g) into 3, which can convert compound 3 into compound 4. The Li reagent was prepared by p-bromostyrene and n-BuLi, and then the No. 4 compound prepared above was added dropwise to finally obtain the vinyl-functionalized 4v-Xantphos ligand. The total yield of the four steps is about 10%, and there is no need for any purification and separation steps in the intermediate preparation process.

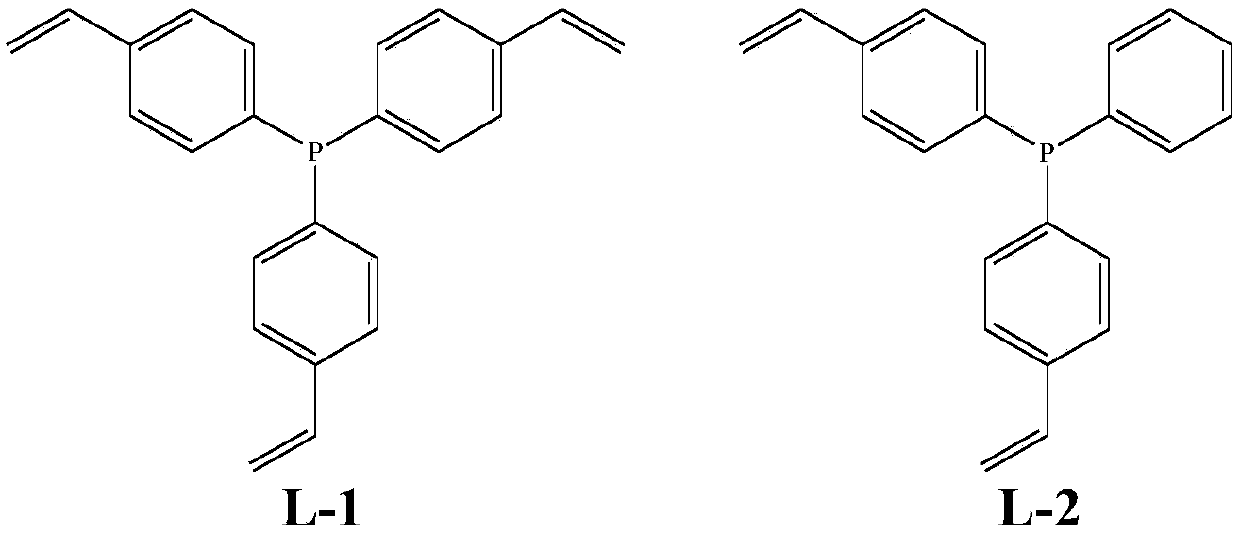

[0051] Preparation of phosphine-containing organic copolymer c...

Embodiment 2

[0054] In Example 2, except taking 10.0 grams of comonomer tris (4-vinylphenyl) phosphine (L1), replacing 2.5 grams of comonomer tris (4-vinylphenyl) phosphine, the rest of the catalyst synthesis process Same as Example 1.

Embodiment 3

[0056] In Example 3, except that 0.1 gram of free radical initiator azobisisobutyronitrile was weighed instead of 1.0 gram of free radical initiator azobisisobutyronitrile, the rest of the catalyst preparation process was the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com