Beneficiation reagent and of separating and recycling precious metal from cooper anode mud using method thereof

A copper anode slime, separation and recovery technology, used in solid separation, flotation and other directions, can solve the problems of high content of precious metals in tailings, immature research, and high content of impurities, so as to reduce lead pollution and smoke pollution, improve labor Conditions and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

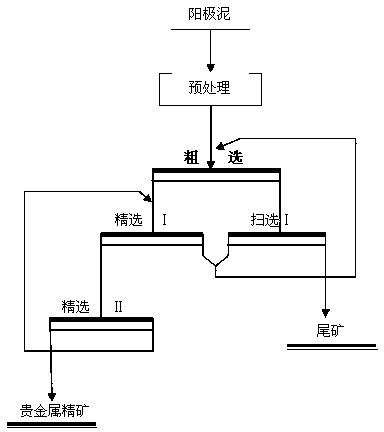

Method used

Image

Examples

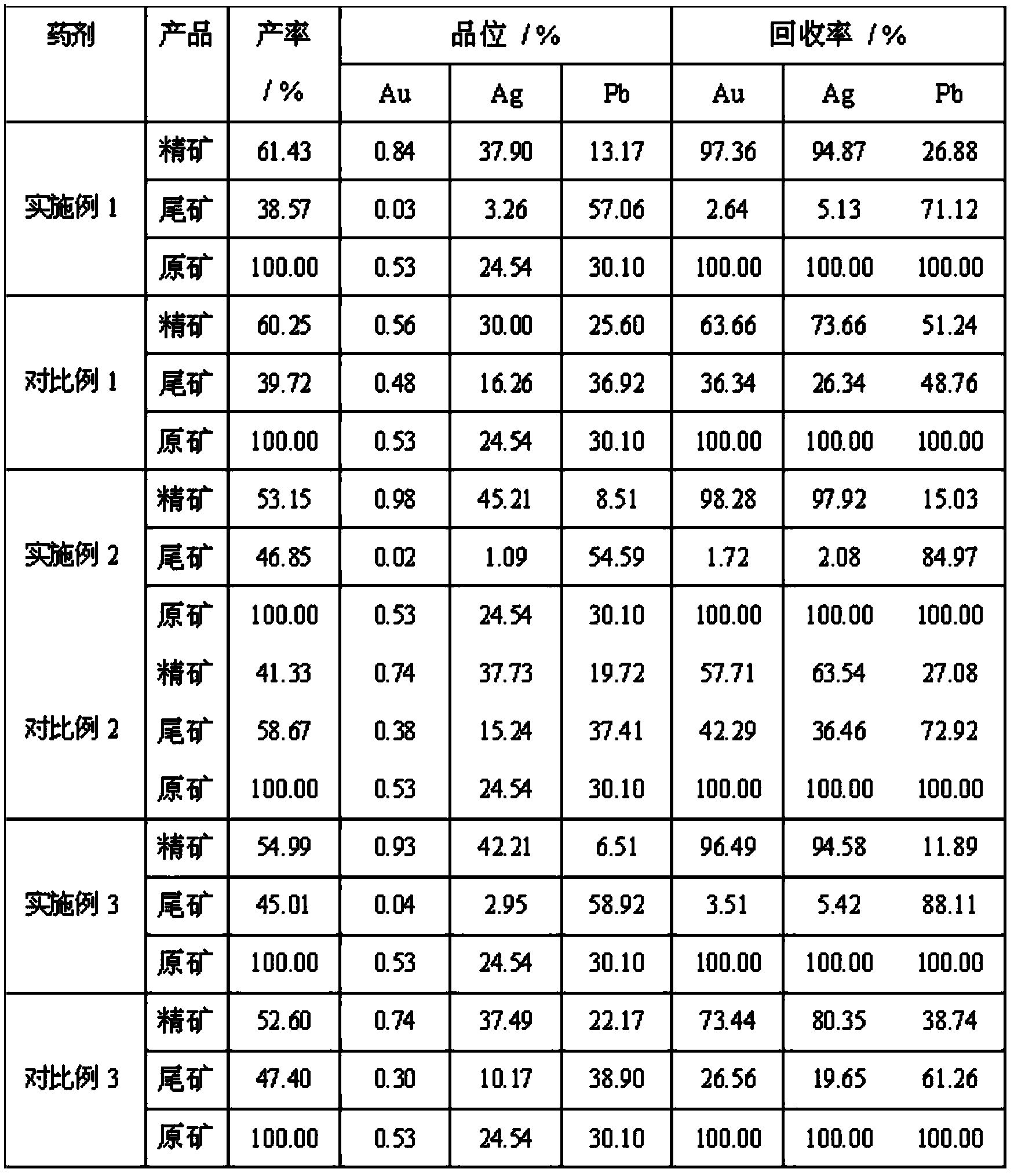

Embodiment 1

[0021] An ore dressing agent for separating and recovering precious metals from copper anode slime, comprising 3 parts by weight of a collector, 10 parts by weight of an inhibitor and 10 parts by weight of a foaming agent, wherein the collector is pinitol Xanthate and pinitol black medicine, the molar ratio of pinitol xanthate and pinitol black medicine is 2:1, the inhibitor is sodium hexametaphosphate, and the foaming agent is pinitol oil.

[0022] The preparation method of the pinitol xanthate is as follows: massaging pinitol oil: sodium hydroxide: carbon disulfide=1:1:1.2, reacting at 15° C. for 3 hours to obtain pinitol xanthate.

[0023] The preparation method of the pinitol black medicine is as follows: according to the molar ratio of pinitol oil: phosphorus pentasulfide: sodium hydroxide = 4:1:2, react at 80° C. for 1 hour to obtain the pinitol black medicine.

[0024] The method for separating and recovering precious metals from copper anode slime by using the above-me...

Embodiment 2

[0038] An ore dressing agent for separating and recovering precious metals from copper anode slime, comprising 10 parts by weight of a collector, 1 part by weight of an inhibitor and 1 part by weight of a foaming agent according to the weight ratio, wherein the collector is pinitol Xanthate and pinitol black medicine, the molar ratio of pinitol xanthate and pinitol black medicine is 100:1, the inhibitor is sodium hexametaphosphate, and the foaming agent is pinitol oil.

[0039] The preparation method of the pinitol xanthate is as follows: massaging pinitol oil: sodium hydroxide: carbon disulfide=1:1:1.2, reacting at 40° C. for 1 hour to obtain pinitol xanthate.

[0040] The preparation method of the pinitol black medicine is as follows: according to the molar ratio of pinitol oil: phosphorus pentasulfide: sodium hydroxide = 4:1:2, react at 20° C. for 3 hours to obtain the pinitol black medicine.

[0041] The method for separating and recovering precious metals from copper anod...

Embodiment 3

[0055] A beneficiation agent for separating and recovering precious metals from copper anode slime, comprising 1 part by weight of collector, 5 parts by weight of inhibitor and 5 parts by weight of foaming agent according to the weight ratio, wherein the collector is pinitol Xanthate and pinitol black medicine, the molar ratio of pinitol xanthate and pinitol black medicine is 1:25, the inhibitor is sodium hexametaphosphate, and the foaming agent is pinitol oil.

[0056] The preparation method of the pinitol xanthate is as follows: massaging pinitol xanthate oil: sodium hydroxide: carbon disulfide=1:1:1.2, reacting at 30°C for 1.5h to obtain pinitol xanthate.

[0057] The preparation method of the pinitol black drug is as follows: according to the molar ratio of pinitol oil: phosphorus pentasulfide: sodium hydroxide = 4:1:2, react at 60° C. for 2 hours to obtain the pinitol black drug.

[0058] The method for separating and recovering precious metals from copper anode slime by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com