Self-cleaning coating for metal substrate and preparation method and use method thereof

A metal-based, self-cleaning technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor scrub resistance, reduced deformation, and poor weather resistance, achieving high market value, Effect of reducing deformation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

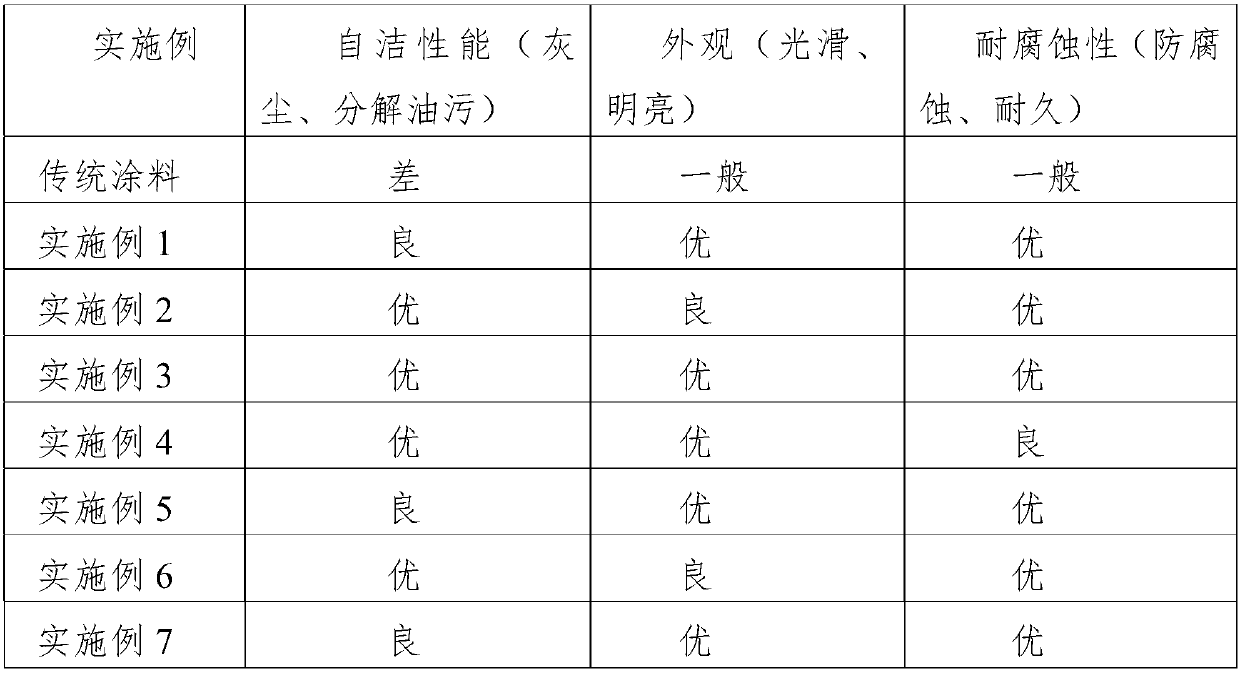

Examples

preparation example Construction

[0057] The present invention also provides a kind of preparation method for the self-cleaning coating of metal base simultaneously, comprises the following steps:

[0058] S1. Select coating raw materials: by mass parts, select polyurethane 62-78.5, nano silicon dioxide 4.2-8.6, butyl acetate 6.5-15, nano talcum powder 5-8, nano titanium dioxide 16-23, ethanol 21-31, propanol 7-15.2, polyvinyl alcohol 4-9.5;

[0059] S2. Prepare the middle layer material: Mix the butyl acetate and polyurethane selected in S1 to form a solution at 10°C-30°C, then add nano-talc powder and nano-silicon dioxide, and stir until it is in an emulsion liquid state, and let it stand After 3h-5h, the intermediate layer coating is obtained;

[0060] S3. Preparation of self-cleaning layer material: mix propanol and ethanol selected in S1 at 10°C-30°C and stir evenly, then add nano titanium dioxide and polyvinyl alcohol into the mixed solution of propanol and ethanol, and stir When it is in emulsion liqu...

Embodiment 1

[0066] Raw material quality: polyurethane 62g, nano silicon dioxide 4.2g, butyl acetate 6.5g, nano talc powder 5g, nano titanium dioxide 16g, ethanol 21g, propanol 7g, polyvinyl alcohol 4g.

[0067] Preparation:

[0068] S1. Select coating raw materials: In terms of parts by mass, 62g of polyurethane, 4.2g of nano-silica, 6.5g of butyl acetate, 5g of nano-talcum powder, 16g of nano-titanium dioxide, 21g of ethanol, 7g of propanol, and polyethylene Alcohol 4g;

[0069] S2. Preparation of the middle layer material: After mixing the butyl acetate and polyurethane selected in S1 to form a solution at 10°C, add nano-talc powder and nano-silica, and stir until it is in an emulsion liquid state. After standing for 3 hours, Get the intermediate coating;

[0070] S3. Preparation of self-cleaning layer material: Mix the propanol and ethanol selected in S1 at 10°C and stir evenly, then add nano-titanium dioxide and polyvinyl alcohol into the mixed solution of propanol and ethanol, and ...

Embodiment 2

[0077] Raw material quality: polyurethane 78.5g, nano silicon dioxide 8.6g, butyl acetate 15g, nano talc powder 8g, nano titanium dioxide 23g, ethanol 31g, propanol 15.2g, polyvinyl alcohol 9.5g.

[0078] Preparation:

[0079] S1. Select coating raw materials: In terms of parts by mass, 78.5g of polyurethane, 8.6g of nano-silicon dioxide, 15g of butyl acetate, 8g of nano-talcum powder, 23g of nano-titanium dioxide, 31g of ethanol, 15.2g of propanol, poly Vinyl alcohol 9.5g;

[0080] S2. Prepare the middle layer material: mix the butyl acetate and polyurethane selected in S1 to form a solution at 30°C, then add nano-talc powder and nano-silicon dioxide, and stir until it is in an emulsion liquid state. After standing for 5 hours, Get the intermediate coating;

[0081] S3. Preparation of self-cleaning layer material: Mix the propanol and ethanol selected in S1 at 30°C and stir evenly, then add nano-titanium dioxide and polyvinyl alcohol into the mixed solution of propanol and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com