Super-hydrophobic self-cleaning surface of wind power vane and preparation method

A wind power blade, self-cleaning technology, applied in wind power generation, wind turbines, mechanical equipment and other directions consistent with the wind direction, can solve the problem of insufficient bonding force between the hydrophobic coating and the substrate, and achieve good designability and flexibility, Wide application range and good process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing the surface of a superhydrophobic self-cleaning wind power blade provided by the invention is characterized in that the method comprises the following steps:

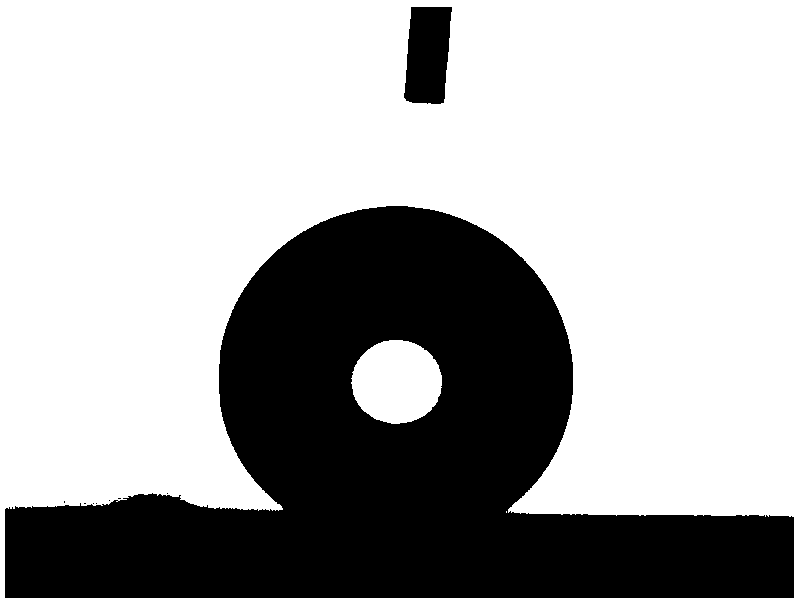

[0034] 1) Using pulsed laser to directly ablate the resin coating on the surface of the blade to prepare a columnar micron-scale structure, based on the inductive effect of the pulsed laser, simultaneously induce the generation of nanoparticles on the outer surface of each columnar micron structure, forming a micron structure plus a nanostructure The micro-nano secondary structure; the columnar micro-structures are densely arranged in quadrilateral or hexagonal shapes on the surface of the blade; the spacing is 30-100 microns. The pulsed laser is generally nanosecond laser, picosecond laser or femtosecond laser.

[0035] 2) Modifying the surface of the wind power blade densely covered with micro-nano secondary structures after the above-mentioned pulsed laser treatment with low surface ener...

Embodiment 1

[0036] Example 1: Preparation of superhydrophobic self-cleaning polyacrylate resin wind turbine blades by femtosecond laser

[0037] The main component of the wind power blade coating treated in this embodiment is polyacrylate resin, including the following steps:

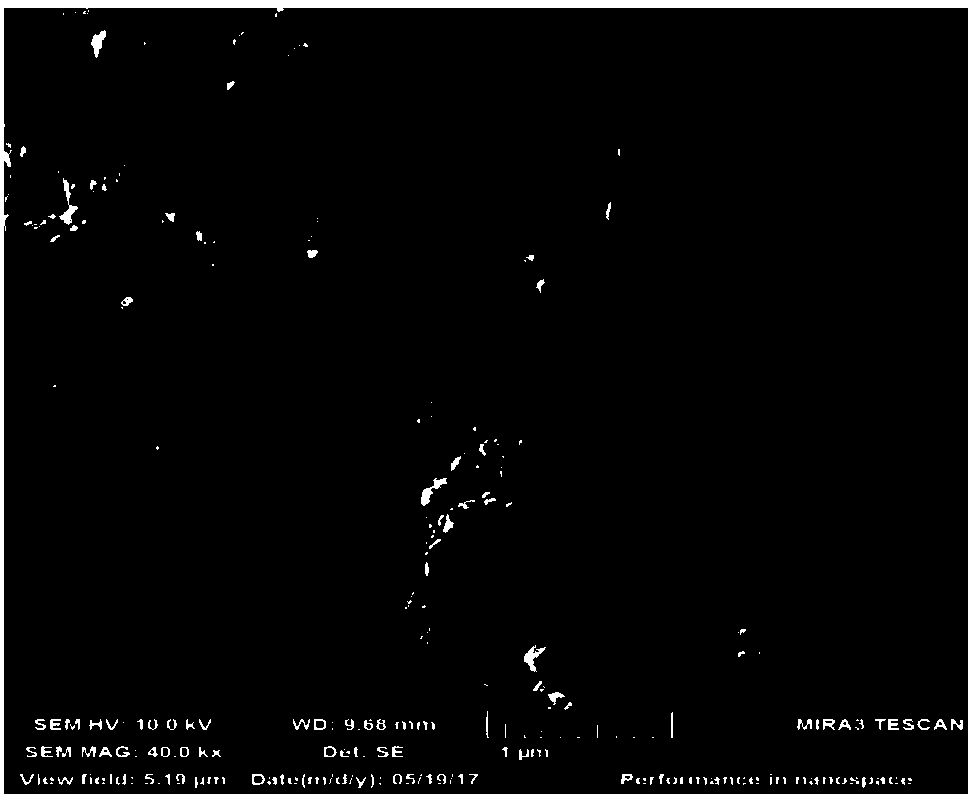

[0038] 1) Ultrasonicate the sample in deionized water for 5 minutes to remove dust, large particles and other dirt on the surface, and then dry it with compressed air. Using femtosecond laser, the laser wavelength is 1.03μm near infrared, the beam is Gaussian distribution, beam quality factor M 2 2 , using a high-speed scanning galvanometer to scan the surface in an orthogonal grid with a line spacing of 40 μm. A groove structure with a period of 40 μm was obtained on the scanned surface, and the height of the microcolumns was measured to be 42.0 μm using a laser confocal microscope. The scanning electron microscope photograph of the obtained structure is as follows Figure 1a As shown, the nanoparticles covered ...

Embodiment 2

[0042] Example 2: Using femtosecond laser to prepare superhydrophobic self-cleaning polyurethane coating wind power blades

[0043] In this embodiment, a material system different from Example 1 is selected as the processing object, and the main component of the processed wind power blade coating is polyurethane resin, including the following steps:

[0044] 1) Ultrasonicate the sample in deionized water for 5 minutes to remove dust, large particles and other dirt on the surface, and then dry it with compressed air. Using femtosecond laser, the laser wavelength is 1.03μm near infrared, the beam is Gaussian distribution, beam quality factor M 2 2 , using a high-speed scanning galvanometer to scan the surface in an orthogonal grid with a line spacing of 40 μm. A columnar structure with a period of 40 μm was obtained on the scanned surface, and the height of the microcolumns was measured to be 37.8 μm using a laser confocal microscope. The scanning electron microscope photograp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com