Special anti-radiation high and low temperature lubricating grease for nuclear grade pump

A lubricating grease and anti-radiation technology, applied in the field of lubricating grease, can solve the problems of leakage of radioactive pollutants, wear, corrosion and cracking, leakage of radioactive pollutants, etc., and achieve excellent radiation resistance, long life, and excellent high and low temperature resistance and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

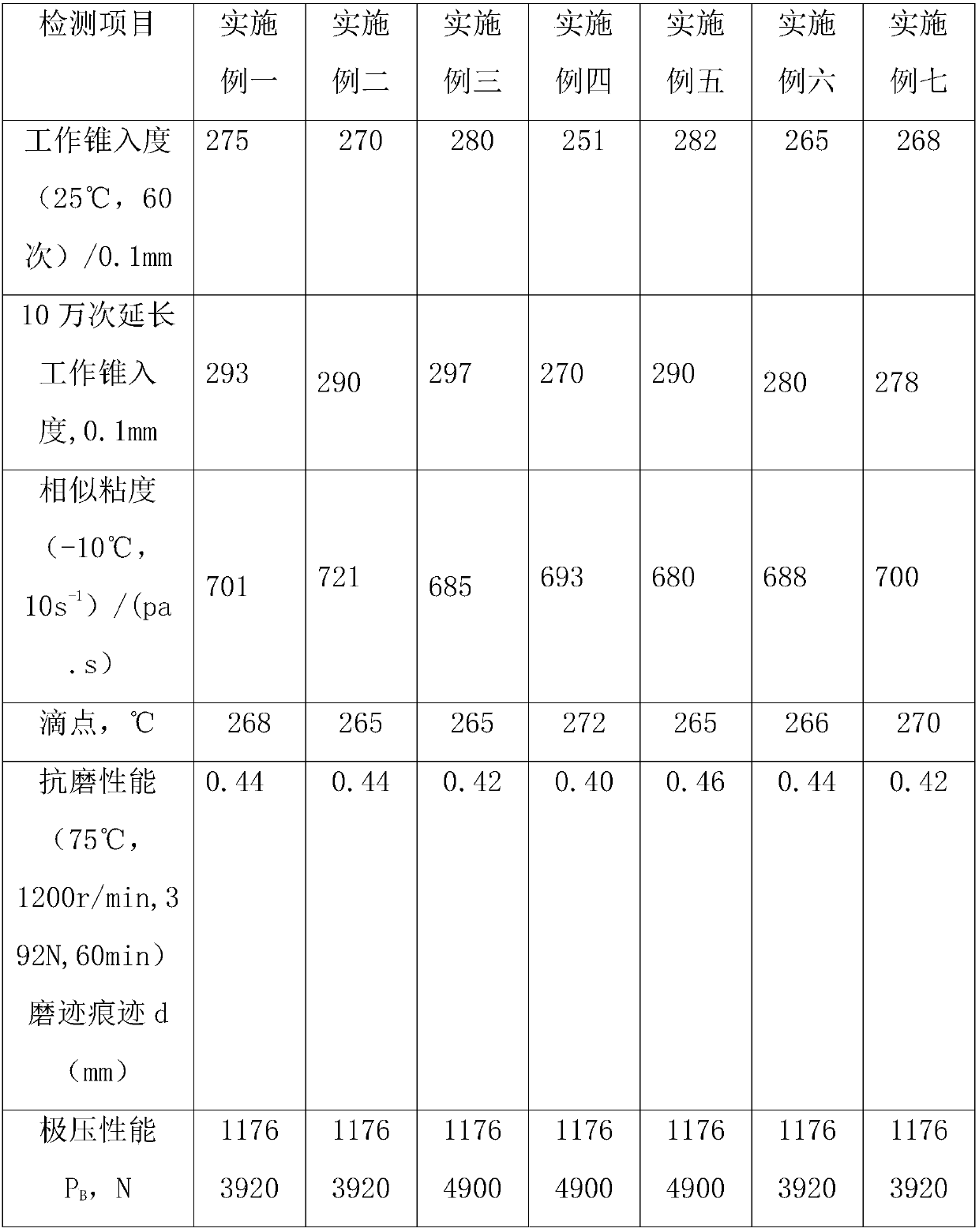

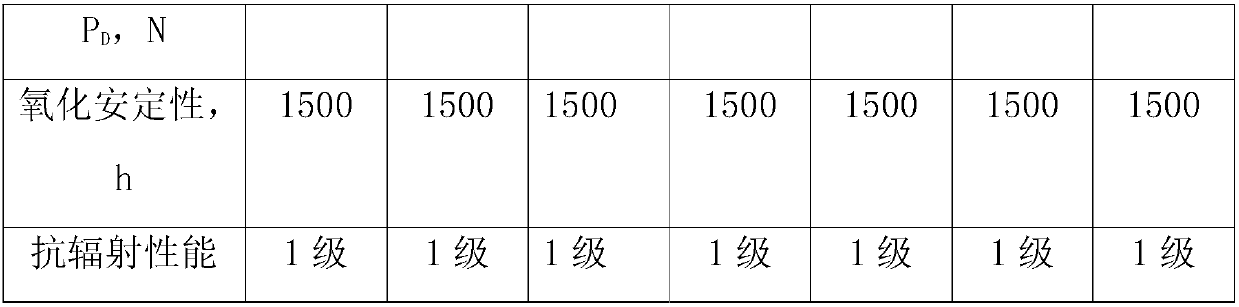

Examples

preparation example Construction

[0022] In this embodiment, the preparation method of the grease includes the following steps: first thicken polyurea powder with alkyl diphenyl ether base oil, then add PTFE micropowder and silicon dioxide, stir and mix for 1 hour, then add zinc oxide and mix well and grind three times; the preparation method adopted is simple and easy to operate, which can not only ensure the full mixing of each raw material component, but also promote the mutual synergy of each raw material component, better exert the performance advantages, and prepare the excellent performance and Lubricating grease that meets the needs of nuclear pumps.

[0023] In this example, all raw material components can be obtained through market purchase.

Embodiment 1

[0026] The anti-radiation high and low temperature special lubricating grease for nuclear-grade pumps provided in this embodiment, the raw materials of the lubricating grease include the following components by weight percentage: 92% of alkyl diphenyl ether (viscosity VG68-220), 3% of polyurea powder, PTFE micropowder 3%, silicon dioxide 1%, zinc oxide (500 mesh) 1%;

[0027] in:

[0028] The purity of the zinc oxide is ≥99.5%;

[0029] The particle size of the PTFE micropowder is ≤5 μm;

[0030] The silicon dioxide is hydrophilic nano-scale silicon dioxide produced by the gas phase method, with a purity of ≥99.0%;

[0031] In this embodiment, the preparation method of the grease includes the following steps: first thicken polyurea powder with alkyl diphenyl ether base oil, then add PTFE micropowder and silicon dioxide, stir and mix for 1 hour, then add zinc oxide and mix well And grind three times, you can.

Embodiment 2

[0033] The anti-radiation high and low temperature special lubricating grease for nuclear-grade pumps provided in this embodiment, the raw materials of the lubricating grease include the following components by weight percentage: 87% of alkyl diphenyl ether (viscosity VG68-220), 5% of polyurea powder, PTFE micropowder 4%, silicon dioxide 2%, zinc oxide (800 mesh) 2%;

[0034] in:

[0035] The purity of the zinc oxide is ≥99.5%;

[0036] The particle size of the PTFE micropowder is ≤5 μm;

[0037] The silicon dioxide is lipophilic nano-scale silicon dioxide produced by the gas phase method, with a purity of ≥99.0%;

[0038] In this embodiment, the preparation method of the grease is the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com