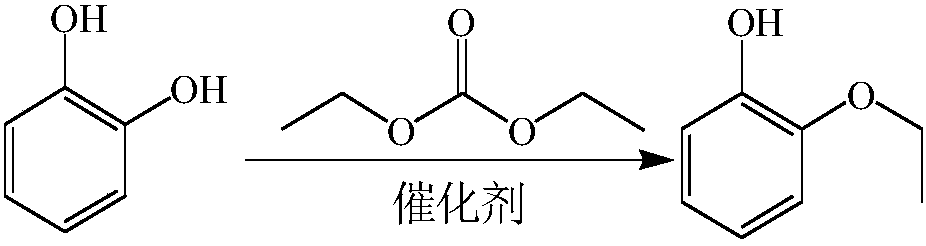

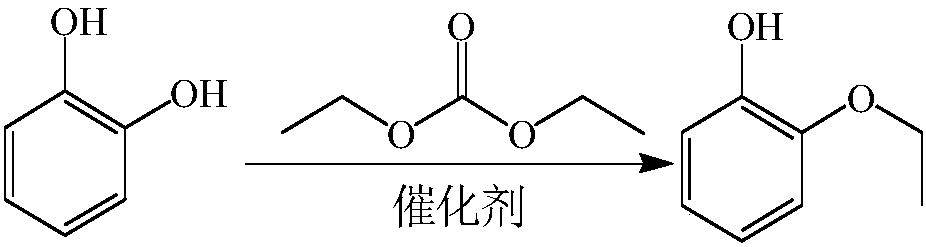

Method for synthesizing ethyl guaiacol

An ethyl guaiacol and equation technology, applied in chemical instruments and methods, ester reaction preparation of ethers, chemical/physical/physical chemical processes, etc., can solve the problem of large amount of alkylating reagents and catalysts, long reaction time, Low selectivity and other problems, to achieve the effect of less side reactions, short residence time, and improved reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 71g of catechol was dissolved in 284g of water to obtain a catechol solution, 6.35g of 18-crown-6 ether was dissolved in 317.5g of a mass concentration of 10wt% sodium hydroxide solution to obtain a catalyst solution, and the catechol solution was , catalyst solution and 39.2mL of diethyl carbonate were respectively injected into the continuously heated microreactor from different microchannels according to the flow rates of 89.3mL / min, 81.6mL / min and 10mL / min respectively, and carried out at normal pressure and 50°C. Reaction, control the residence time of the material in the microreactor to 5min, add the mixed solution after the reaction to ethyl acetate for extraction, the ethyl acetate is recovered and recycled, the water phase is adjusted to PH = 2 with hydrochloric acid, and the solid is precipitated, filtered , then rinsed with cold water, dried to obtain ethyl guaiacol, the gas chromatography detection content was 98.4%, the conversion rate of catechol was 95.1%,...

Embodiment 2

[0032] 150g catechol was dissolved in 225g ethanol to obtain catechol solution, and 1.496g 15-crown-5 ether was dissolved in 267g mass concentration to obtain catalyst solution in potassium hydroxide aqueous solution of 28wt%. , catalyst solution and 331mL diethyl carbonate were injected into the continuously heated microreactor from different microchannels at the flow rates of 100mL / min, 71.6mL / min and 89.5mL / min respectively, and the reaction was carried out at normal pressure and 150°C , control the residence time of the material in the microreactor to 0.5min, add the mixed solution after the reaction to extract with ether, recover and recycle the ether, adjust the water phase to PH=3 with sulfuric acid, wait for the solid to precipitate, filter, and then use cold water After rinsing and drying, ethyl guaiacol was obtained. The content detected by gas chromatography was 98.5%, the conversion rate of catechol was 96.5%, and the selectivity of ethyl guaiacol was 88.1%. The NMR...

Embodiment 3

[0036] 71g pyrocatechol was dissolved in 250g benzene to obtain pyrocatechol solution, 10.2g18-crown-6 ether was dissolved in 668g mass concentration to obtain catalyst solution in 15wt% sodium carbonate aqueous solution, pyrocatechol solution, Catalyst solution and 78.5mL diethyl carbonate were injected into the continuously heated microreactor from different microchannels at the flow rates of 47.6mL / min, 100mL / min, and 11.6mL / min respectively, and the reaction was carried out at normal pressure and 120°C , control the residence time of the material in the microreactor to 1min, add the mixed solution after the reaction to extract with ethyl acetate, recover and recycle the ethyl acetate, adjust the water phase to PH=2.2 with phosphoric acid, wait for the solid to precipitate, filter, After rinsing with cold water and drying to obtain ethyl guaiacol, the content detected by gas chromatography is 98.4%, the conversion rate of catechol is 96.5%, the selectivity of ethyl guaiacol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com