Nano-silver loaded graphene antibacterial agent and graphene in-situ reduction nano-silver loaded water-based antibacterial coating

A graphene and nano-silver technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve poor dispersion, antibacterial efficiency, insufficient antibacterial persistence, and low utilization of silver components and other problems, to achieve the effect of increasing the specific surface area, excellent antibacterial effect, and reducing the particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

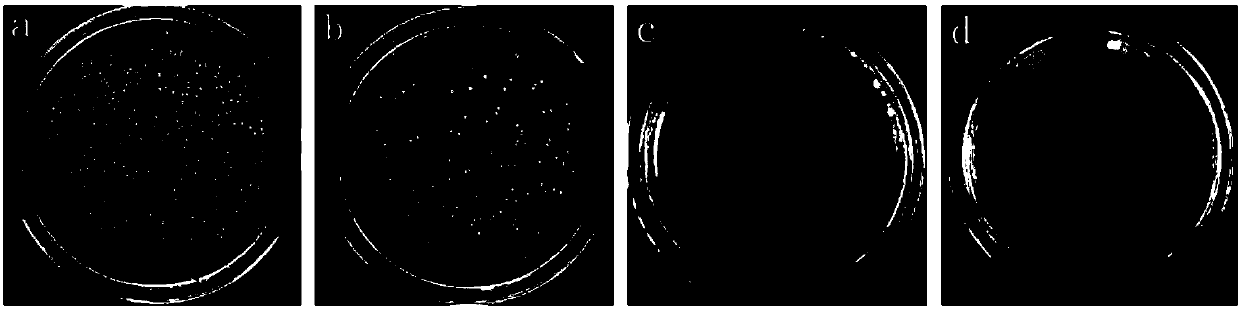

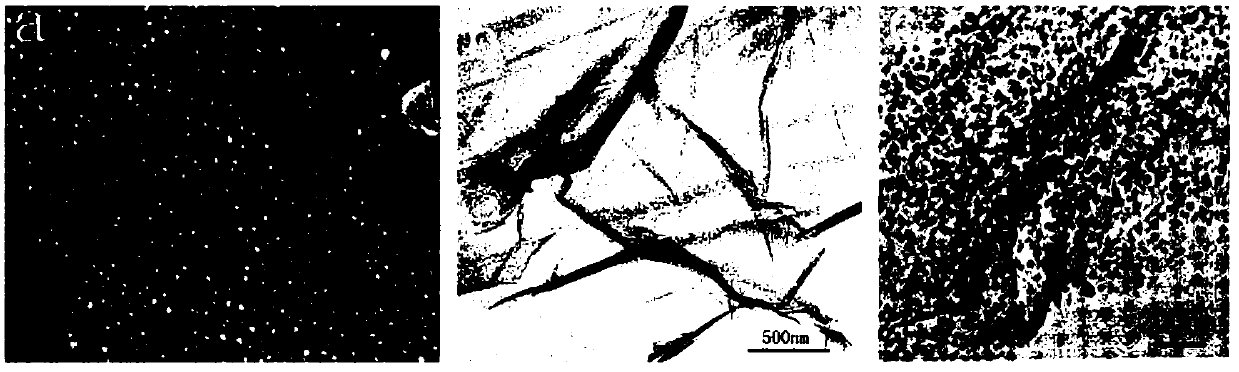

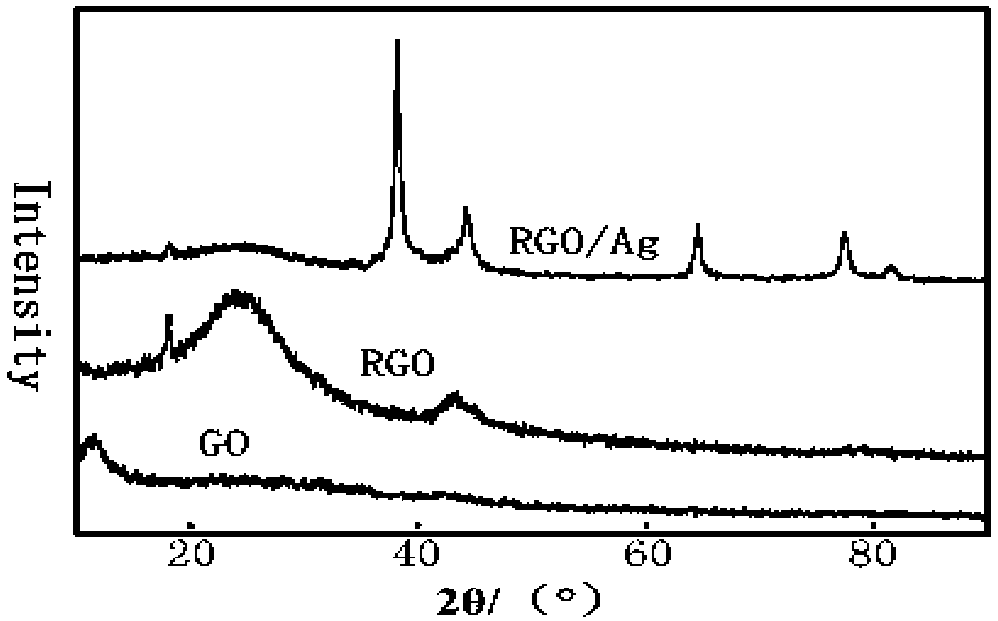

Image

Examples

preparation example Construction

[0040] The preparation method step of described graphene-supported nano-silver antibacterial agent is as follows:

[0041] Step 1. Prepare graphene oxide by the improved Hummers method; slowly add 23-40mL of concentrated sulfuric acid into a beaker with 1-2g flake graphite at room temperature, and stir evenly; after stirring for 15min, add 3-4.5g of potassium permanganate Slowly add it into the above beaker, stir for 4 hours; then slowly add 25-50mL of deionized water into the above beaker, then add hydrogen peroxide drop by drop at room temperature until the liquid in the beaker turns golden yellow; finally use hydrochloric acid and deionized Washing with ionic water until the pH is 7, and freeze-drying for 8 hours to obtain graphene oxide;

[0042] Step 2, carry out surface modification treatment to the graphene oxide obtained in step 1 with 3-aminopropyltriethoxysilane; disperse the graphene oxide obtained in step 1 in ethanol solution, described ethanol solution is made of...

Embodiment 1

[0045] A kind of graphene in-situ reduction loaded nano-silver water-based antibacterial coating comprising the graphene-loaded nano-silver antibacterial agent prepared by the above-mentioned preparation method, embodiment 1 disclosed by the invention, in parts by weight, its raw materials consist of:

[0046]

[0047]

Embodiment 2

[0048] A kind of graphene in-situ reduction loaded nano-silver water-based antibacterial coating comprising the graphene-loaded nano-silver antibacterial agent prepared by the above-mentioned preparation method, embodiment 2 disclosed by the invention, in parts by weight, its raw materials consist of:

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com