Preparation method for durable anti-bacterial fabric

An antibacterial fabric, durable technology, applied in the direction of plant fiber, animal fiber, textile and paper making, etc., to achieve the effect of obvious antibacterial effect, less damage to the original performance of the fabric, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

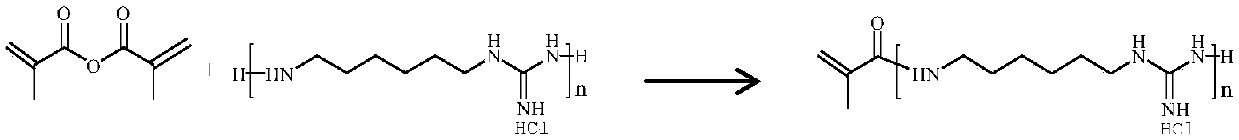

[0038] (1) Dissolve 5 g of polyhexamethylene guanidine hydrochloride in 25 mL of deionized water, add 3.5 mL of triethylamine, stir to mix the solution well, then add 8 mL of dioxane solution containing 4 g of methacrylic anhydride dropwise , continue to react for 8h, the product is precipitated with acetone and then dried in a vacuum oven at room temperature to obtain the antibacterial monomer.

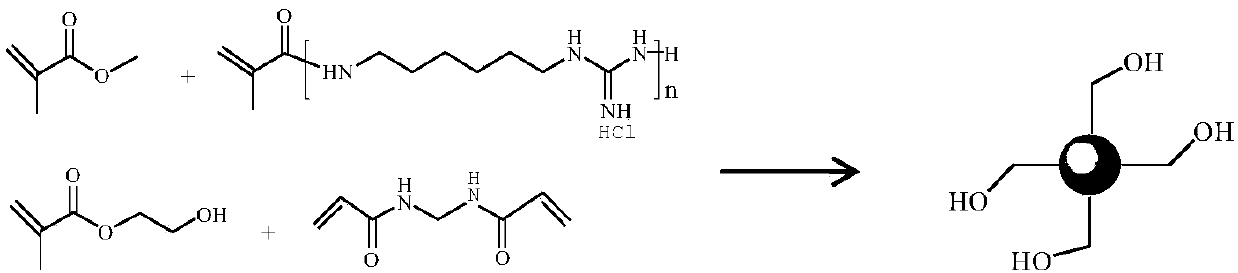

[0039](2) In a 250mL three-necked flask, 5g of the antibacterial monomer in step (1), 1.8g of methyl methacrylate and 0.2g of hydroxyethyl methacrylate were dissolved in 100mL of deionized water, and 0.1g of N,N- For methylene bisacrylamide, heat up to 70°C with nitrogen gas for 30 minutes, add 2 mL of an aqueous solution containing 70 mg ammonium persulfate APS dropwise, and continue the reaction for 12 hours. The reaction product is filtered and purified three times, and dried in a vacuum oven at 40°C. antibacterial nanohydrogels.

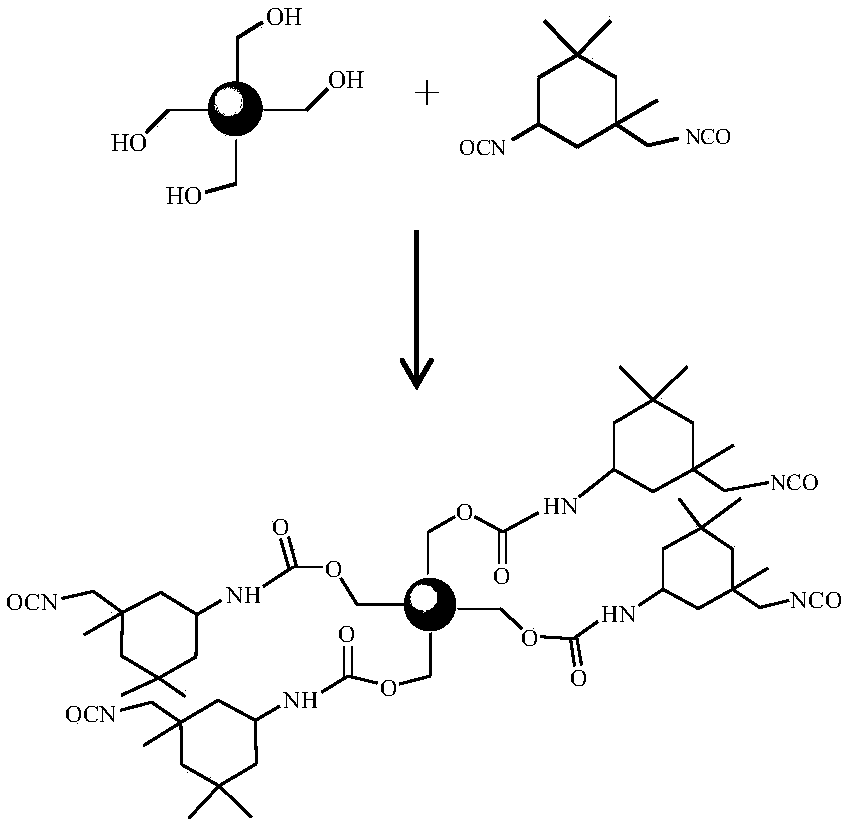

[0040] (3) Dissolve 0.3 g of the antibacterial n...

Embodiment 2

[0047] (1) Dissolve 5 g of polyhexamethylene guanidine hydrochloride in 25 mL of deionized water, add 3.5 mL of triethylamine, stir to mix the solution well, then add 8 mL of dioxane solution containing 4 g of methacrylic anhydride dropwise , continue to react for 8h, the product is precipitated with acetone and then dried in a vacuum oven at room temperature to obtain the antibacterial monomer.

[0048] (2) In a 250mL three-necked flask, dissolve 8g of the antibacterial monomer in step (1), 1.8g of styrene and 0.2g of hydroxyethyl methacrylate in 100mL of deionized water, and add 0.1g of N,N-methylene For bisacrylamide, heat up to 70°C with nitrogen gas for 30 minutes, add 2 mL of an aqueous solution containing 70 mg of ammonium persulfate APS dropwise, and continue the reaction for 12 hours. The reaction product is filtered and purified three times, and dried in a vacuum oven at 40°C to obtain antibacterial nanoparticles Hydrogels.

[0049] (3) Dissolve 0.3 g of the antibac...

Embodiment 3

[0053] (1) Dissolve 5g of L-arginine in 25mL of deionized water, and add 3.5mL of triethylamine, stir to mix the solution well, then add 8mL of dioxane solution containing 4g of methacrylic anhydride dropwise, continuously After reacting for 8 hours, the product was precipitated with acetone and then dried in a vacuum oven at room temperature to obtain the antibacterial monomer.

[0054] (2) In a 250mL three-necked flask, dissolve 5g of the antibacterial monomer in step (1), 1.8g of styrene and 0.2g of hydroxyethyl methacrylate in 100mL of deionized water, and add 0.1g of N,N-methylene For bisacrylamide, heat up to 70°C with nitrogen gas for 30 minutes, add 2 mL of an aqueous solution containing 70 mg of ammonium persulfate APS dropwise, and continue the reaction for 12 hours. glue.

[0055] (3) Dissolve 0.3g of the antibacterial nano-hydrogel in step (2) in 100mL petroleum ether, ultrasonically disperse for 30min, add 2mL isophorone diisocyanate dropwise, add 0.1mL dibutylti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com