Conducting material doped PDMS composite film capable of improving longitudinal electric charge density of generator frictional layer and preparation method thereof

A nano-generator and conductive material technology, applied in triboelectric generators, metal material coating process, coating and other directions, can solve the problem of rarely researching the spatial structure of the friction layer, and achieve increased output, high charge density, and low impedance. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

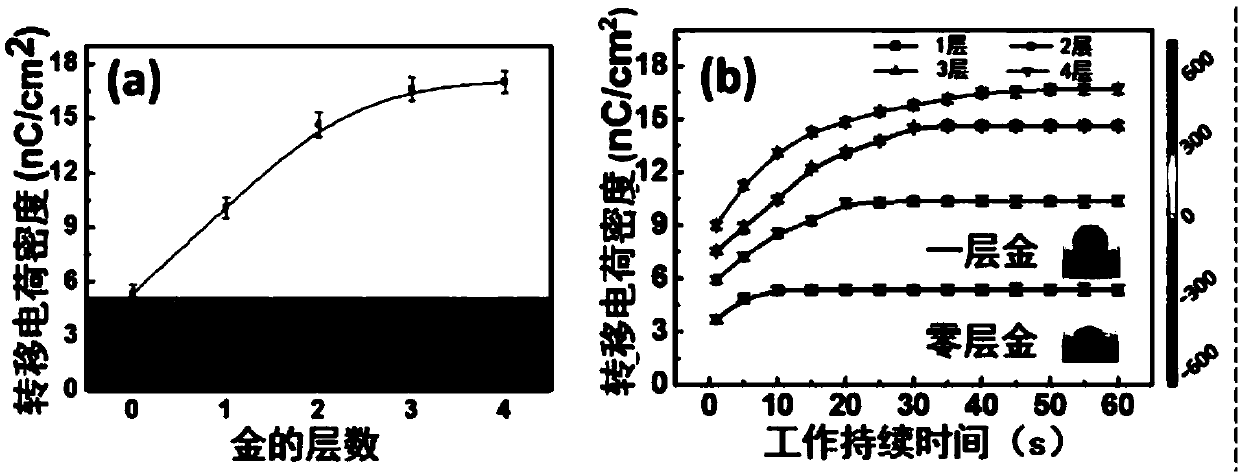

[0026] Example 1 Assembly of gold composite film nanogenerator (G-TENG)

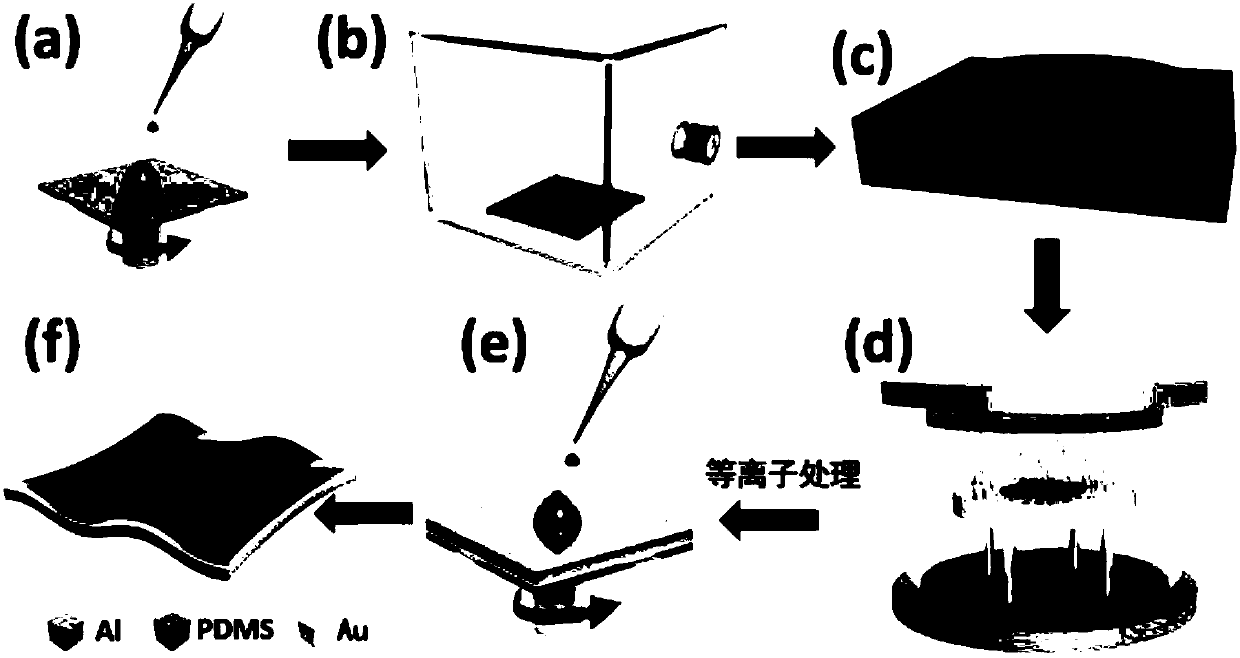

[0027] Prepare the PDMS composite film (i.e. the negative friction layer of G-TENG) that is mixed with conductive material of the present invention to improve the longitudinal charge density of the nanogenerator friction layer, and operate according to the following steps (flow process is as follows: figure 1 shown):

[0028] 1) Take a square acrylic board with a side length of 4 cm (PVC or wood or glass or resin board or polyimide board or PET board or nylon board or PP board or PMMA board or PTFE board) as a lining On the bottom, attach a piece of aluminum foil of the same size to the acrylic board with double-sided polyimide tape.

[0029] 2) Spin-coat PDMS solution (silicone resin 184, Dow Corning) on the aluminum foil, the speed of spin-coating is 100-8000rpm, the spin-coating time is 5-100s, after spin-coating, vacuumize in the vacuum chamber for 10-120 minutes, Then place it on a heating plate...

Embodiment 2

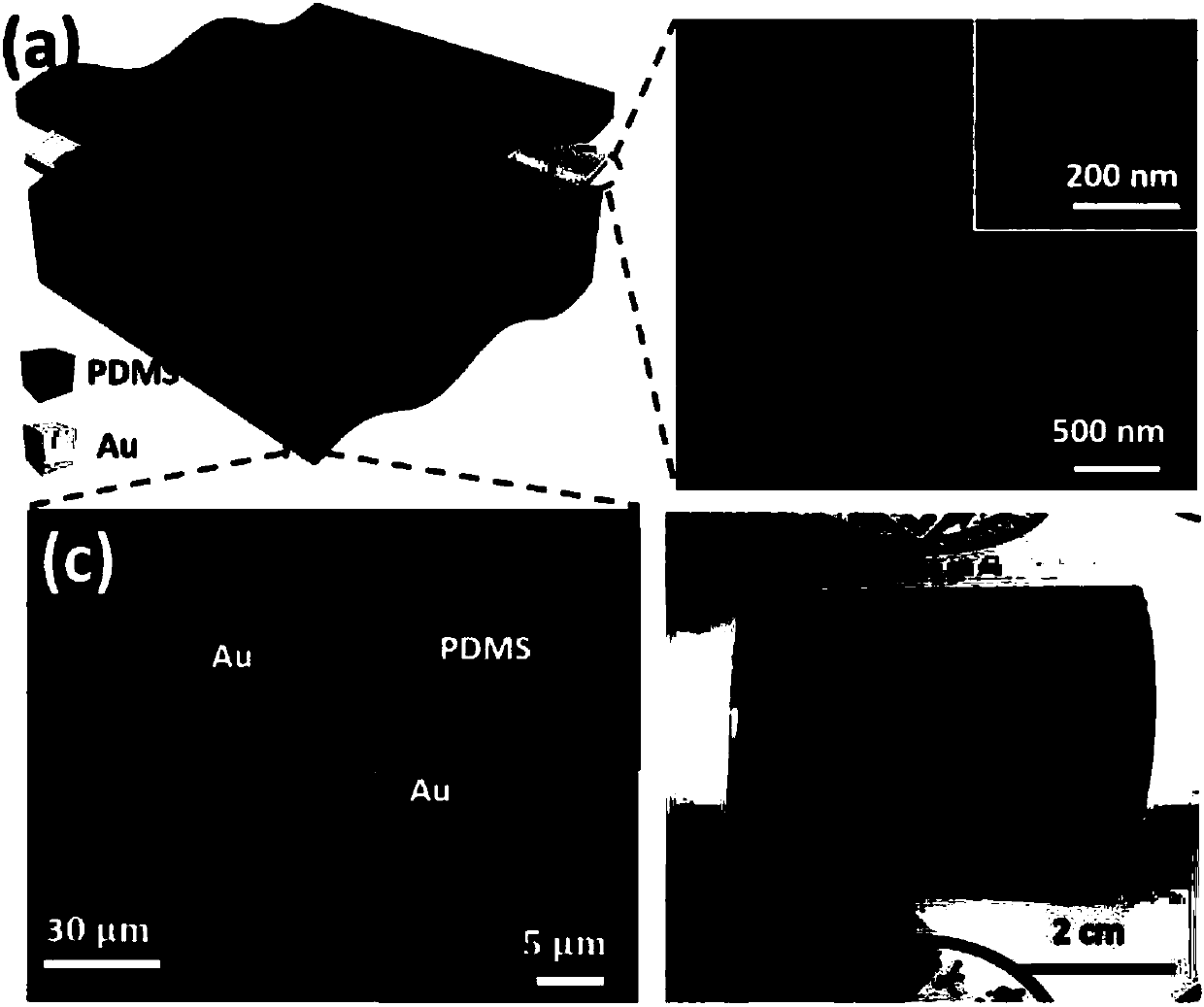

[0042] Example 2 Preparation of the PDMS composite membrane of the present invention

[0043] Prepare the PDMS composite membrane that has 3 layers of gold layers according to the method for embodiment 1, and its structural representation is as follows Figure 5 As shown, from bottom to top are: substrate 1, aluminum foil layer 2, first PDMS layer 3, three layers of Au-PDMS composite layer 4, the Au-PDMS composite layer 4 is composed of gold layer 5 and above the gold layer The second PDMS layer 6 is composed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com