Fast absorption type water-absorbent resin and preparation method thereof

A water-absorbent resin, absorbent technology, applied in absorbent pads, medical science, etc., can solve the problems of slow absorption, non-absorptive fracture surface, reverse osmosis, etc., to increase specific surface area, control acrylic acid residue, and water absorption speed. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

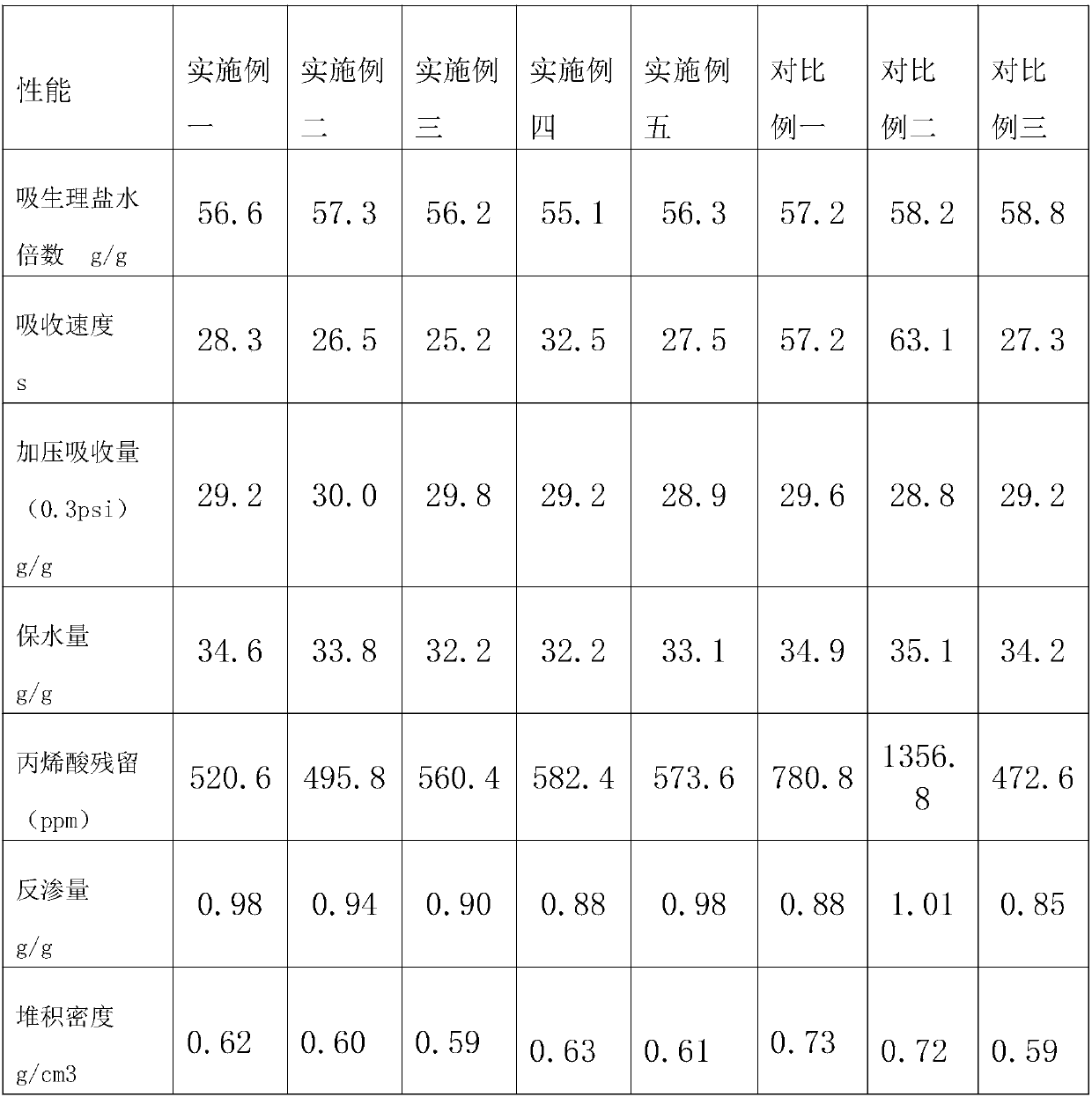

Embodiment 1

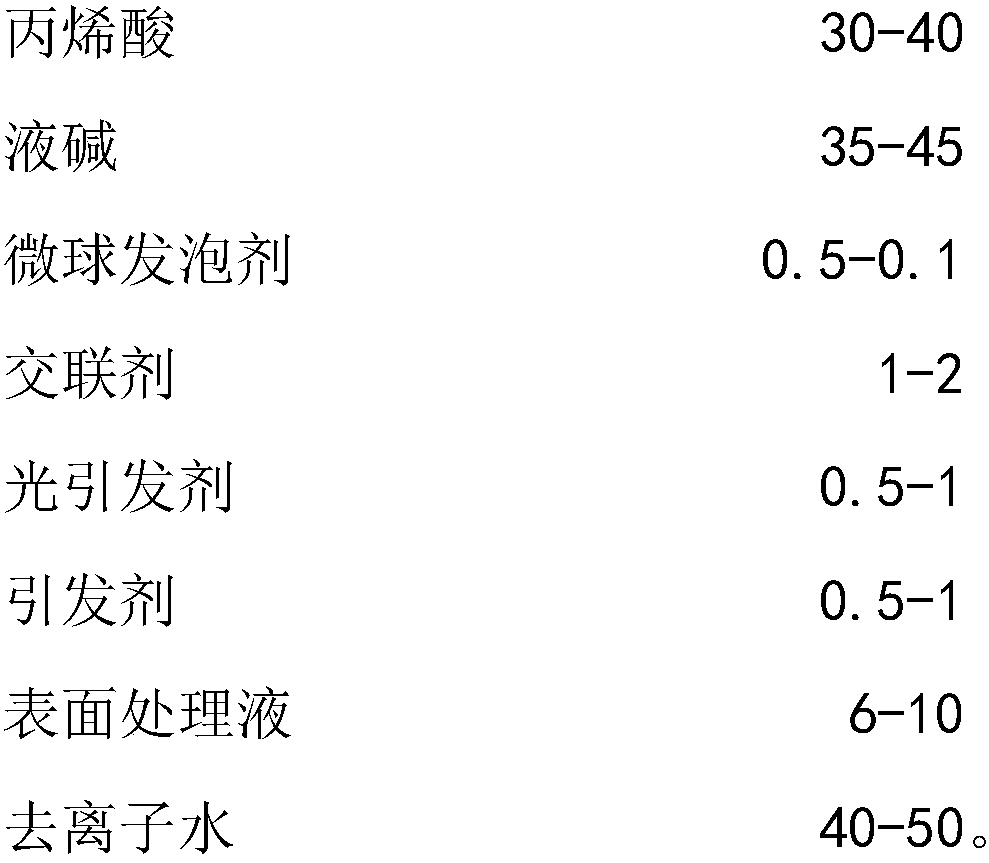

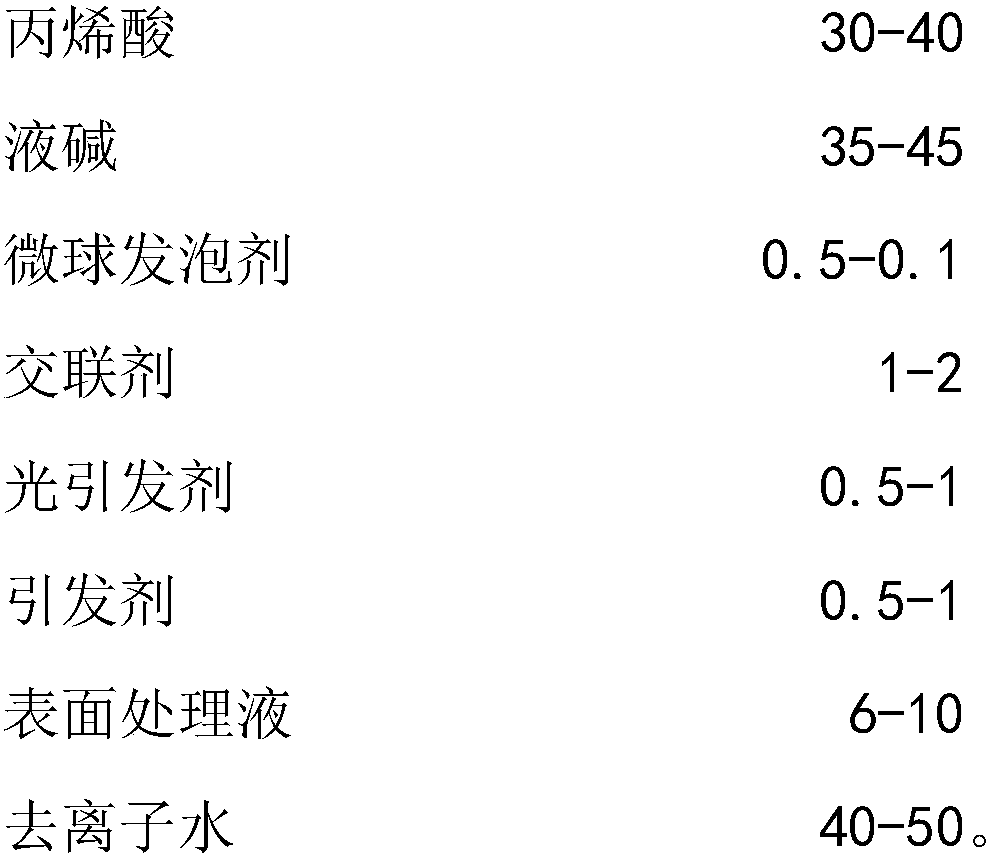

[0035] A fast-absorbing water-absorbing resin, comprising the following components in parts by weight:

[0036] 30 parts of acrylic acid; 40 parts of deionized water; 35 parts of 32% sodium hydroxide aqueous solution; microsphere foaming agent refers to 0.5 part of macromolecular hollow microspheres coated with nano-calcium carbonate on the surface of acrylic resin; 1 part of a mixture of methylbisacrylamide and polyethylene glycol dimethacrylate with a mass ratio of 1:1; photoinitiator 1-hydroxycyclohexyl phenyl ketone and 2,4,6-trimethylbenzene 0.5 parts of acyl-diphenylphosphine oxide mass ratio of 2:1 mixture; 0.5 parts of cumene hydroperoxide as initiator; 6 parts of surface treatment solution.

[0037] (1) Mix 30 parts of acrylic acid and 40 parts of deionized water, then add 35 parts of 32% sodium hydroxide aqueous solution for neutralization reaction, control the reaction temperature <40 °C; then add 0.5 parts of microsphere foaming agent, 1 part of Cross-linking agen...

Embodiment 2

[0043] A fast-absorbing water-absorbing resin, comprising the following components in parts by weight:

[0044] 35 parts of acrylic acid; 45 parts of deionized water; 40 parts of 32% sodium hydroxide aqueous solution; microsphere foaming agent refers to 0.8 part of macromolecule hollow microspheres coated with nano-calcium carbonate on the surface of acrylic resin; 1.5 parts of a mixture of methylbisacrylamide and polyethylene glycol dimethacrylate with a mass ratio of 1:1; photoinitiators 1-hydroxycyclohexyl phenyl ketone and 2,4,6-trimethylbenzyl 0.8 parts of acyl-diphenylphosphine oxide mass ratio of 2:1 mixture; 0.8 parts of cumene hydroperoxide as initiator; 8 parts of surface treatment solution.

[0045] (1) Mix 35 parts of acrylic acid and 45 parts of deionized water, then add 40 parts of 32% sodium hydroxide aqueous solution for neutralization reaction, control the reaction temperature <40°C; then add 0.8 parts of microsphere foaming agent, 1.5 parts of Cross-linking ...

Embodiment 3

[0051] A fast-absorbing water-absorbing resin, comprising the following components in parts by weight:

[0052] 40 parts of acrylic acid; 50 parts of deionized water; 45 parts of 32% sodium hydroxide aqueous solution; microsphere foaming agent refers to 1 part of polymer hollow microspheres coated with nano-calcium carbonate on the surface of acrylic resin; 2 parts of a mixture of methylbisacrylamide and polyethylene glycol dimethacrylate with a mass ratio of 1:1; photoinitiators 1-hydroxycyclohexyl phenyl ketone and 2,4,6-trimethylbenzene 1 part of acyl-diphenylphosphine oxide mass ratio of 2:1 mixture; initiator refers to 1 part of cumene hydroperoxide; 10 parts of surface treatment solution.

[0053] (1) Mix 40 parts of acrylic acid and 50 parts of deionized water, then add 45 parts of 32% sodium hydroxide aqueous solution for neutralization reaction, control the reaction temperature <40°C; then add 1 part of microsphere foaming agent, 2 parts of Cross-linking agent, 1 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com