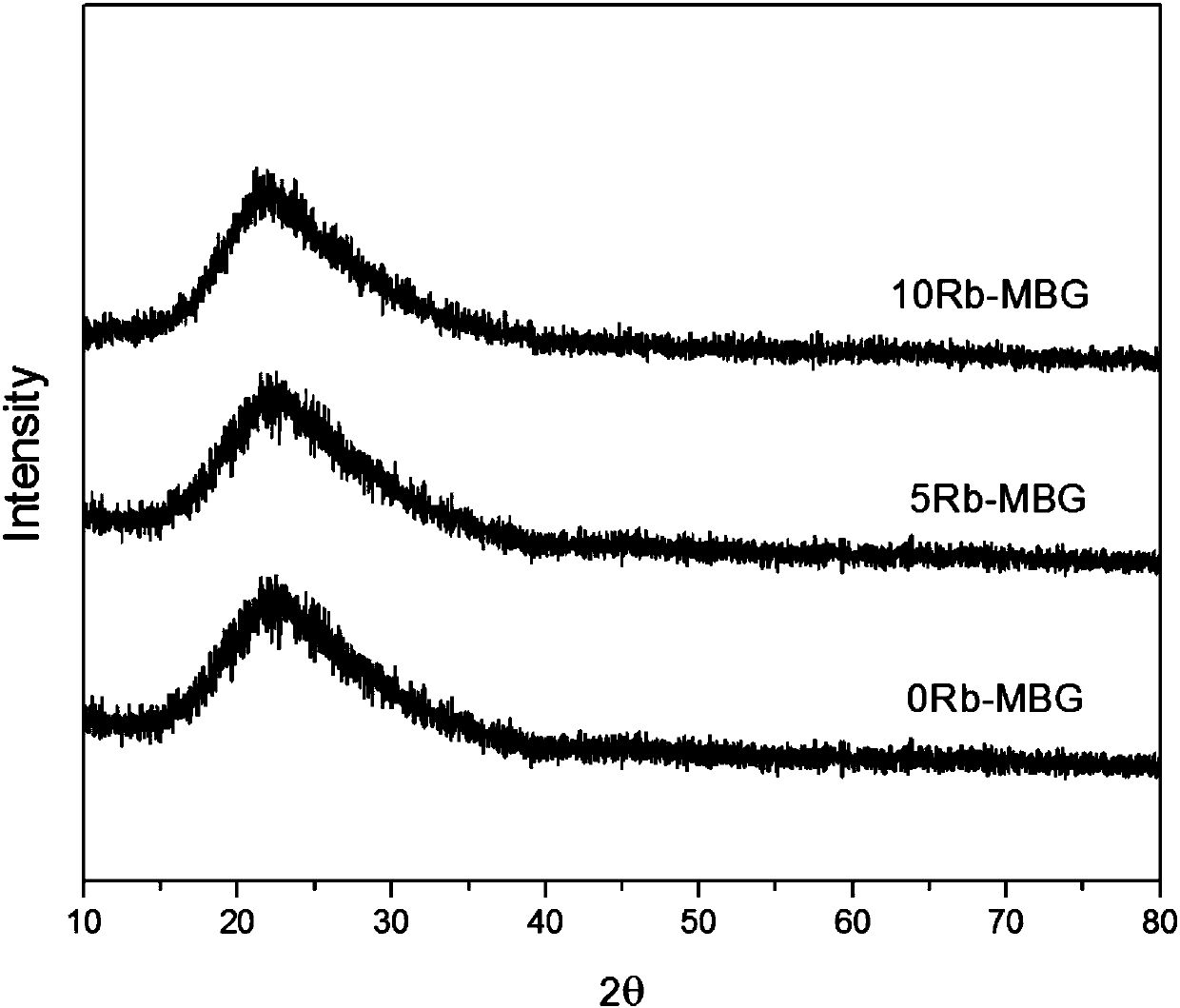

Rubidium-containing multistage mesoporous bioactive glass, and preparation method and application thereof

A bioactive glass and mesoporous technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of shortening the preparation time, achieve the effects of shortening the time, high specific surface area, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of rubidium-free MBG described in this embodiment comprises the following steps:

[0040] a Dissolve 8g of P123, 2.79g of calcium nitrate, 1.44g of triethyl phosphate, and 13.4g of ethyl orthosilicate in 120g of ethanol to obtain solution A, in which the molar ratio of calcium, phosphorus and silicon is 15:5:80.

[0041] b The solutions were mixed in a beaker at 20° C. and stirred by means of a magnetic stirrer for 12 hours.

[0042] c Immerse the polyurethane sponge in the gel for 10 minutes, then transfer the sponge to a petri dish, heat it with a hair dryer, and dry it for 5 minutes, and repeat this step 4 times.

[0043] d After being completely dried, calcined at 700° C. for 5 hours to obtain a rubidium-free mesoporous bioactive glass drug carrier.

Embodiment 2

[0045] The preparation method of rubidium-containing MBG described in this embodiment comprises the following steps:

[0046] a Dissolve 8 g of template agent P123, 1.86 g of calcium nitrate, 1.44 g of triethyl phosphate, and 13.4 g of ethyl orthosilicate in 120 g of ethanol to obtain solution A.

[0047] b Dissolve 0.48 g of target dopant rubidium chloride in 10 ml of deionized water to obtain solution B, in which the molar ratio of rubidium, calcium, phosphorus, and silicon is 5:10:5:80.

[0048] c Pour solution B into solution A and mix in a beaker at 20°C, and stir for 12 hours with the help of a magnetic stirrer to obtain a mixed gel.

[0049] d Immerse the polyurethane sponge in the obtained gel for 10 minutes, transfer the sponge to a petri dish, heat it with a hair dryer, and dry it for 5 minutes, and repeat this step 4 times.

[0050] e After being completely dried, it was calcined at 700° C. for 5 hours to obtain a rubidium-containing mesoporous bioactive glass drug c...

Embodiment 3

[0052] The preparation method of rubidium-containing MBG described in this embodiment comprises the following steps:

[0053] a Dissolve 8 g of template agent P123, 0.93 g of calcium nitrate, 1.44 g of triethyl phosphate, and 13.4 g of ethyl orthosilicate in 120 g of ethanol to obtain solution A.

[0054] b Dissolve 0.96 g of the target dopant rubidium chloride in 20 ml of deionized water to obtain solution B, in which the molar ratio of the four elements of rubidium, calcium, phosphorus, and silicon is 10:5:5:80.

[0055] c Pour solution B into solution A and mix in a beaker at 20°C, and stir for 12 hours with the help of a magnetic stirrer to obtain a mixed gel.

[0056] d Immerse the polyurethane sponge in the obtained gel for 10 minutes, transfer the sponge to a petri dish, heat it with a hair dryer, and dry it for 5 minutes, and repeat this step 4 times.

[0057] e After being completely dried, calcined at 700° C. for 5 hours to obtain a rubidium-containing mesoporous bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com