Nano-engineered coatings for anode active materials, cathode active materials, and solid-state electrolytes and methods of making batteries containing nano-engineered coatings

A cathode active material and solid electrolyte technology, applied in the field of electrochemical batteries, can solve the problems of infeasible all-solid-state secondary batteries, inability to manufacture solid-state batteries, and unrecoverable capacity loss, achieve high capacity, prevent side reactions, and eliminate resistance effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

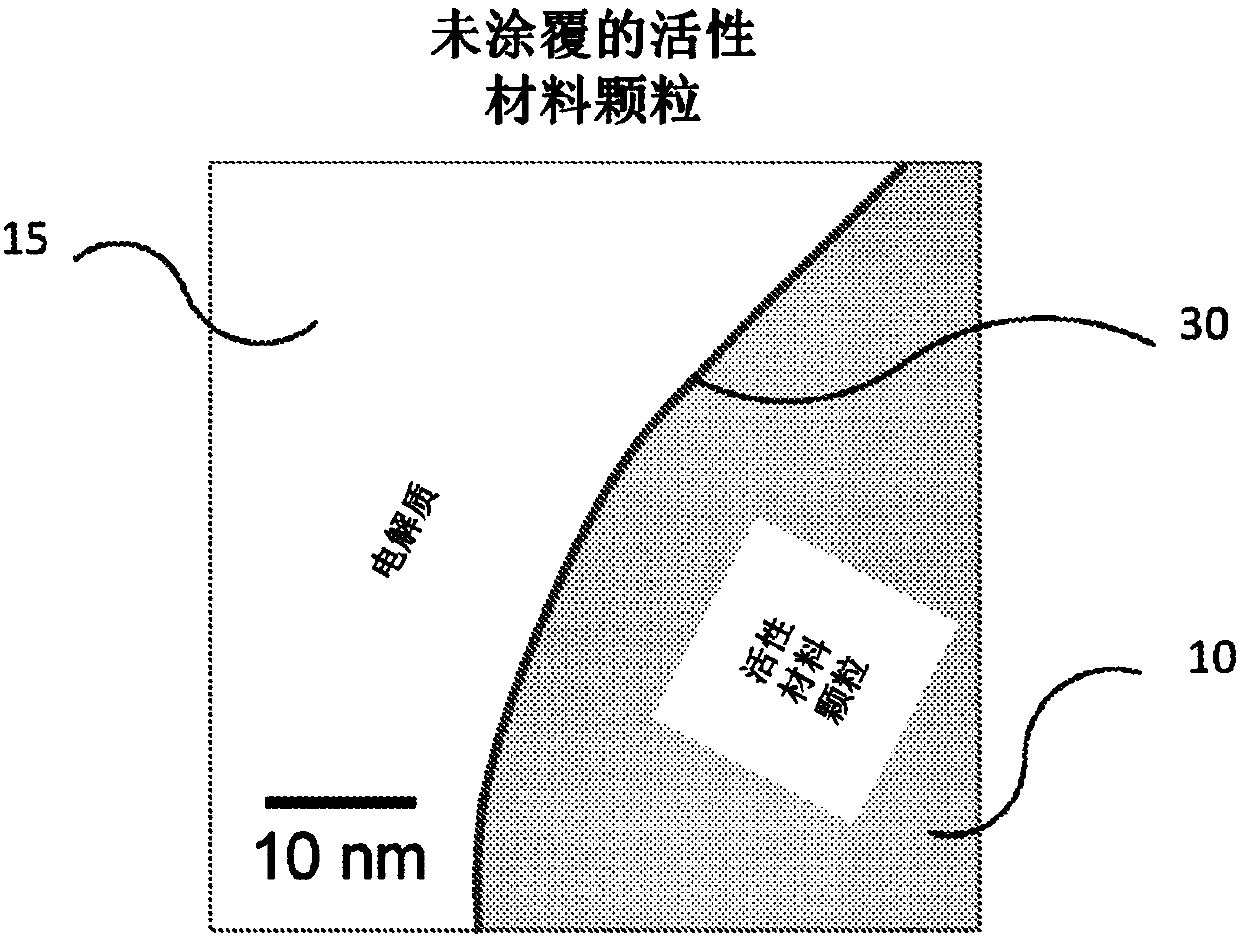

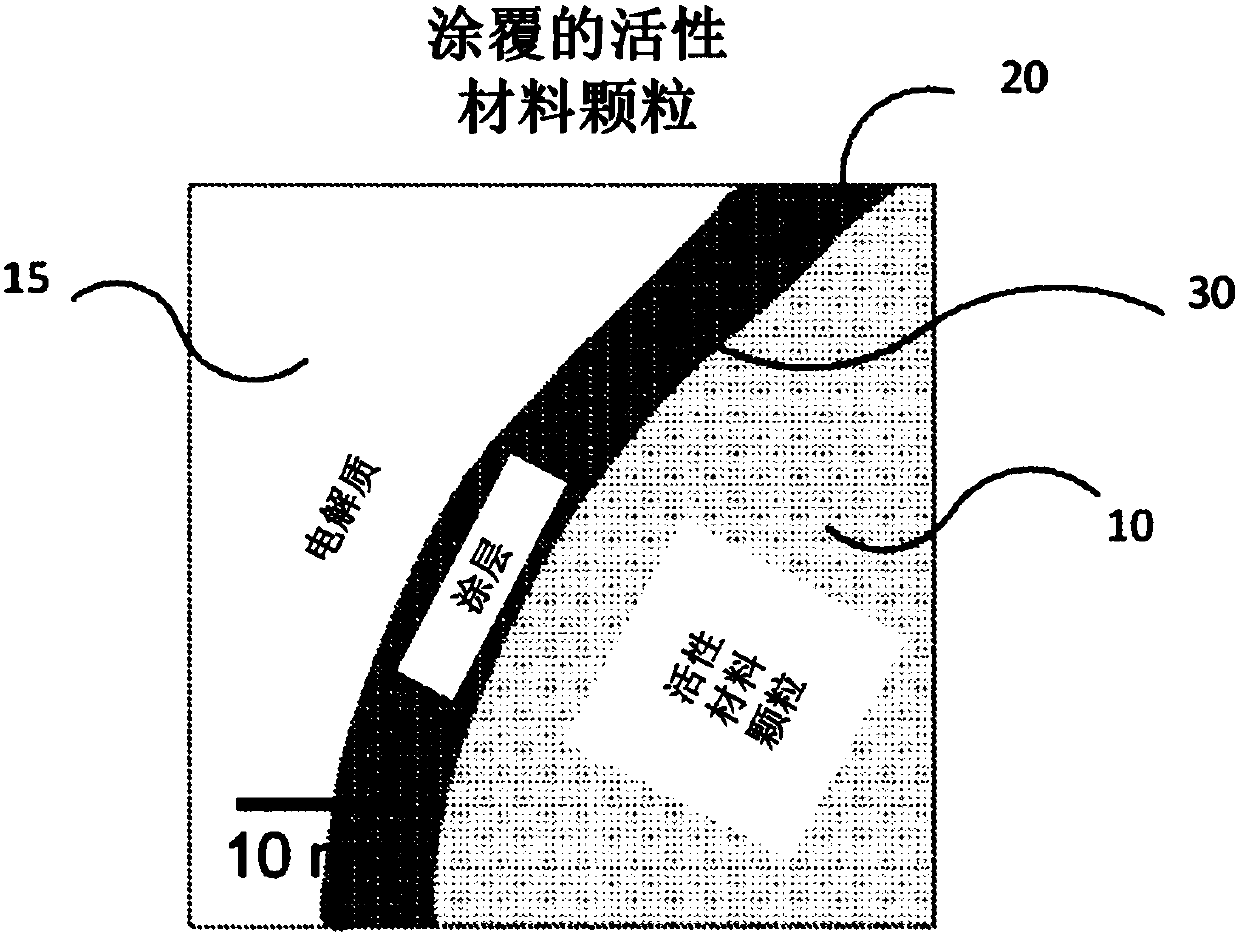

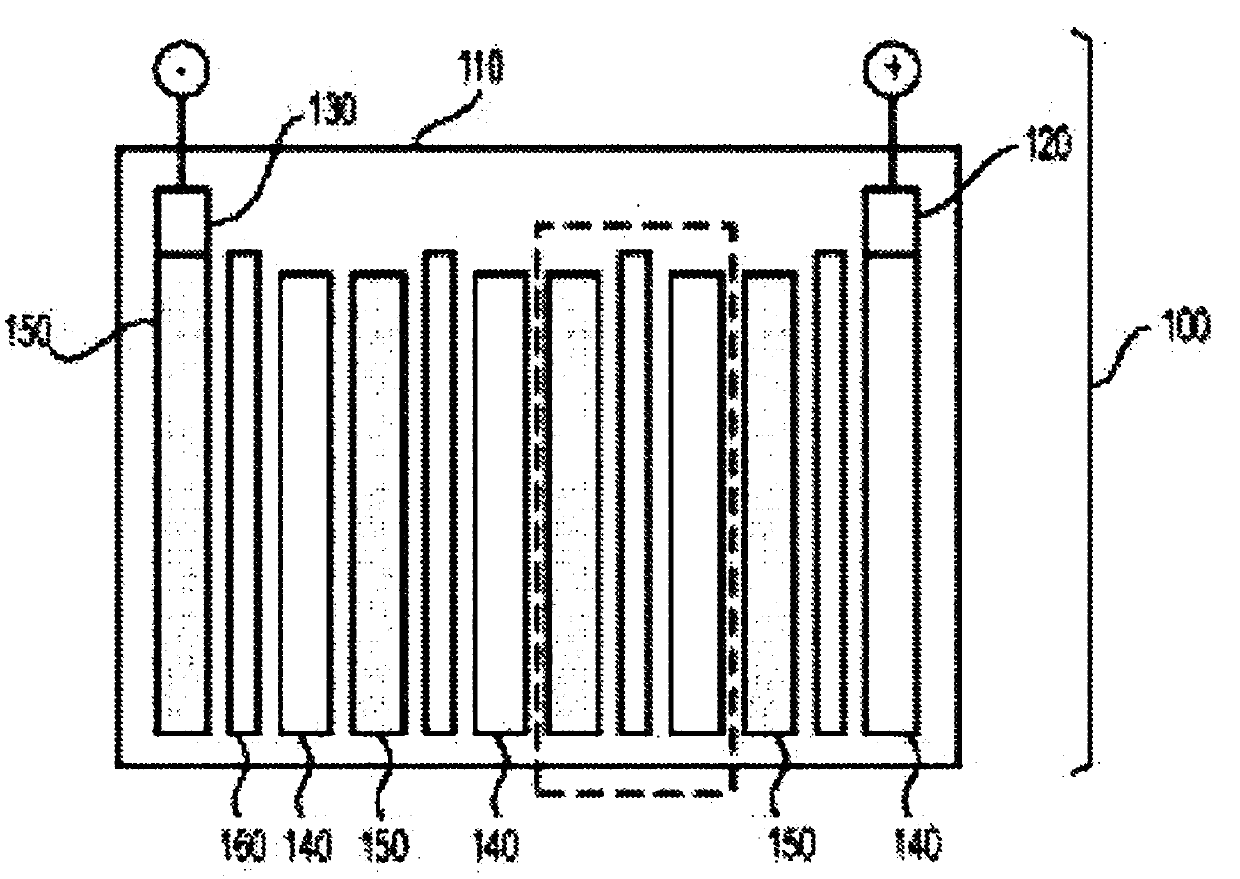

[0175] Embodiments of the present invention were prepared on NMC 811 using an alumina coating. The active material NMC 811 powder is processed by atomic layer deposition to deposit Al on the active material particles of NMC 811 2 o 3 coating. Atomic layer deposition is typically performed at temperatures ranging from room temperature to over 300°C and at deposition rates sufficient to ensure a satisfactory coating while providing good throughput. sufficient to deposit 10 nm Al on NMC active material particles 2 o 3 In coating conditions, NMC 811 powder was applied by ALD process. The coated particles are then used to form an active material slurry that is applied to a current collector to form an electrode. The electrodes were then fabricated into batteries and tested against the uncoated active material.

[0176] The full battery cycle life of the coating material is as Figure 7C 33% improvement under the indicated C / 3 cycle rate, in such as Figure 8A 38% improvemen...

Embodiment 2

[0179] Embodiments of the present invention were prepared using alumina coatings on NCA. The active material NCA powder is processed by atomic layer deposition to deposit Al on the active material particles of NCA 2 o 3coating. Atomic layer deposition is typically performed at temperatures ranging from room temperature to over 300°C and at deposition rates sufficient to ensure a satisfactory coating while providing good throughput. sufficient to deposit 10 nm of Al on NCA active material particles 2 o 3 Under the conditions of the coating, the NCA powder is coated by the ALD process. The coated particles are then used to form a slurry for the active material, which is applied to a current collector to form an electrode. The electrodes were then fabricated into batteries and tested against the uncoated active material.

[0180] Such as Figure 9A As shown, the full battery cycle life of the coating material is increased by 31% at a 1C cycle rate. Such as Figure 9C As ...

Embodiment 3

[0182] Embodiments of the present invention were prepared using titania coatings on NCA. The active material NCA powder is processed by atomic layer deposition, and TiO is deposited on the NCA active material particles 2 coating. Atomic layer deposition is typically performed at temperatures ranging from room temperature to over 300°C and at deposition rates sufficient to ensure a satisfactory coating while providing good throughput. sufficient to deposit 10 nm of TiO on NCA active material particles 2 Under the conditions of the coating, the NCA powder is coated by the ALD process. The coated particles are then used to form a slurry for the active material, which is applied to a current collector to form an electrode. The electrodes were then fabricated into batteries and tested against the uncoated active material.

[0183] Such as Figure 9A As shown, the full battery cycle life of the coating material is increased by 57% at a 1C cycle rate. Such as Figure 9C As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com