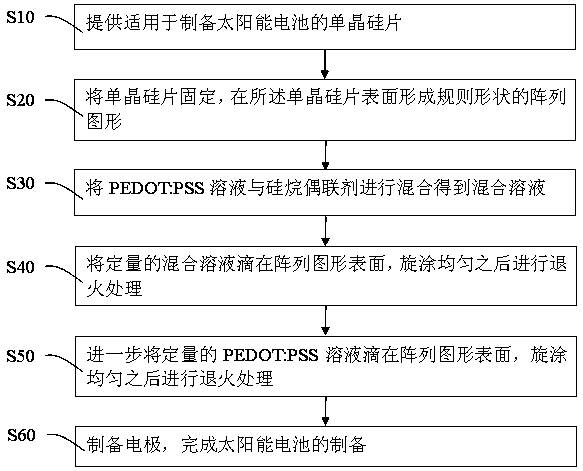

Solar battery preparation method

A solar cell and electrode preparation technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as coating, and achieve the effects of good compatibility, reduced aspect ratio, excellent light trapping and passivation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The essence of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the content of the present invention is not limited thereto.

[0034] Due to the low efficiency of thin-film silicon / PEDOT:PSS heterojunction solar cells at this stage, the interface problem is one of the main reasons restricting its efficiency. The quality of the mass junction, and because the nanostructure has a larger specific surface area, there are more surface dangling bonds, and the surface recombination of photogenerated carriers is more serious. Although the interface modification layer has a high open-circuit voltage Voc for PEDOT:PSS / silicon hybrid cells, some processes still use complex coating processes and expensive vacuum systems to increase the complexity of process operation and equipment costs, which do not meet Low-cost photovoltaic development direction.

[0035] Based on this, the present invention provides a kind of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com