Composite filter paper for filter and preparation method of composite filter paper

A technology of filter paper and filter layer, which is applied in the field of composite filter paper for filter and its preparation, can solve the problems of poor folding and difficult to meet process requirements, and achieves increased absorption capacity, is conducive to design and installation, and has good air permeability and capacity. The effect of dust rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of negatively charged moxa moss mid-length fibers:

[0034] Get moxa moss and carry out ultrafine pulverization to obtain moss moss superfine powder, disperse in 75% ethanol, make the solution that mass concentration is 10%, then add moxa moss: the mass ratio of dimer acid is the ratio of 1:0.2 Polyacid is uniformly dispersed by high-speed mechanical stirring, and then placed in a pressure capillary rheometer at 180°C and 7MPa to flow out naturally, cooled, and the filaments are collected, and the filaments are cut into lengths of 60 μm to obtain negative charges. Modified moxa medium long fiber.

Embodiment 2

[0035] Example 2 Preparation of positively charged moxa short fiber:

[0036] Take moxa and carry out ultrafine pulverization to obtain superfine powder of moxa, disperse it in water to make a solution with a mass concentration of 10%, and then press moxa: the mass ratio of polyamide polyamine epichlorohydrin is 1:0.2 Add polyamide polyamine epichlorohydrin, disperse evenly through high-speed mechanical stirring, then place it in a pressure capillary rheometer at 180°C and 10MPa to flow out naturally, cool, collect filaments, and cut the filaments The length is 10 μm, and the medium-long fibers of positively charged moxa powder are obtained.

Embodiment 3

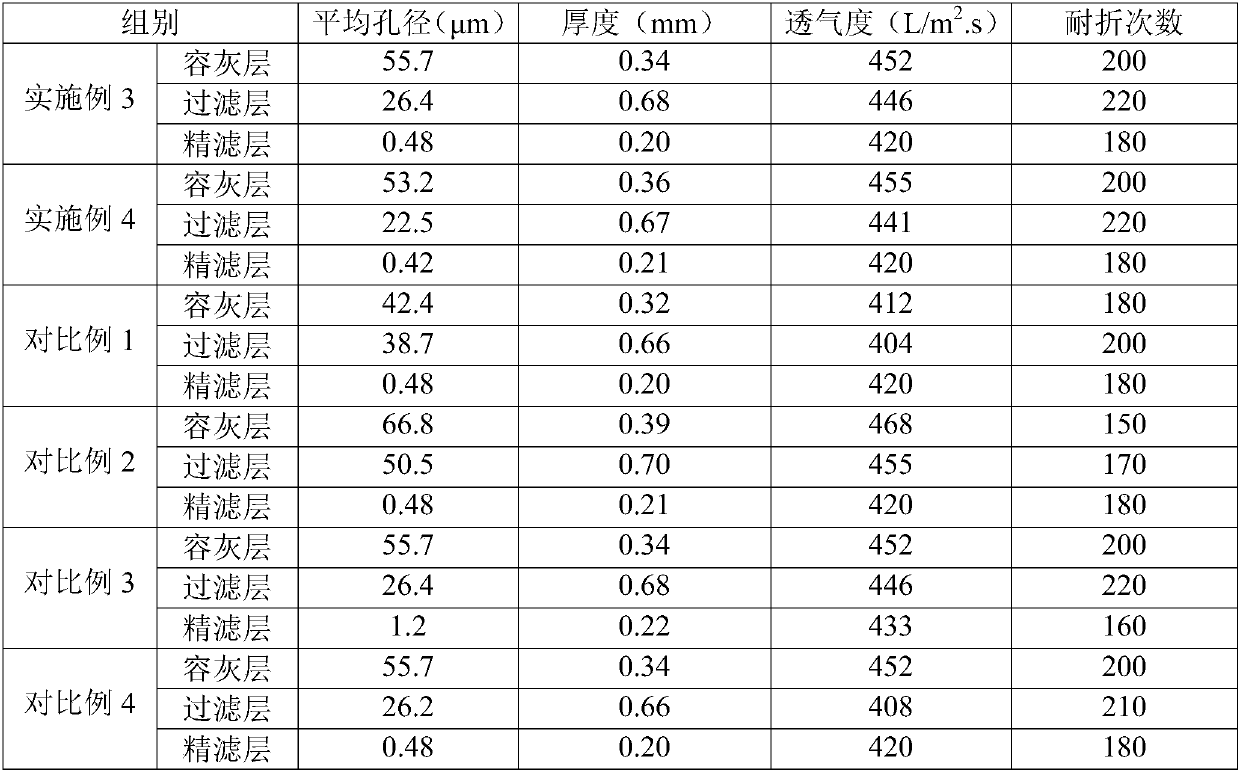

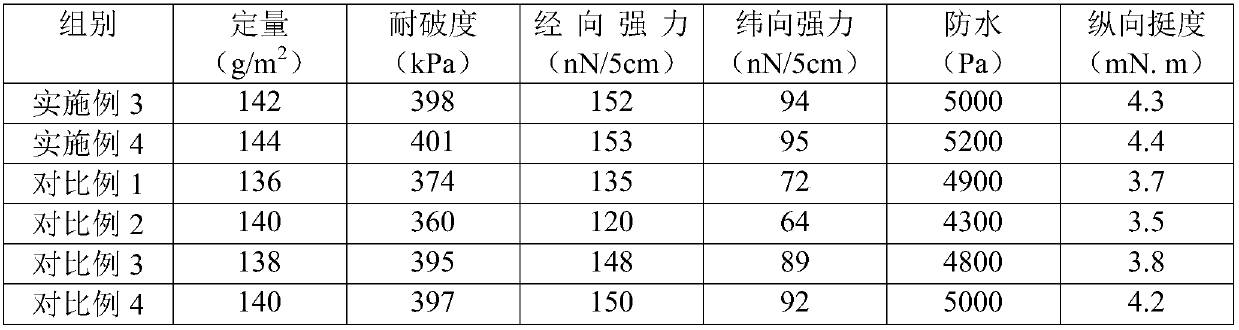

[0037] Example 3 Preparation of composite filter paper

[0038] (1) Preparation of ash-holding layer: Take 100 parts of corn bio-based fiber, 100 parts of negatively charged moxa moss mid-length fiber, 20 parts of organic flexible fiber, and 10 parts of polycarbodiimide. The mass concentration is 0.3%, and then the impurity is removed, and after being deflagged by a deflaker, the pulp is refined, and finally the pulp is sent to an inclined wire former to form a wet paper, which is dried.

[0039] (2) Preparation of filter layer: take 100 parts of seaweed carbon fiber, 100 parts of positively charged moxa short fiber, 40 parts of ethyl cellulose, 15 parts of aluminum oxide, and 2 parts of cetyltrimethylammonium bromide After mixing, dilute the slurry obtained by beating to a mass concentration of 1%, then remove impurities, and then refine the pulp after being decomposed by a deflagging machine, and finally transport the slurry to an inclined wire former to form wet paper, soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com