Sneaker sole

A technology for sports shoes and soles, applied in the field of sports shoes, can solve the problems of wear resistance, low mechanical strength, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

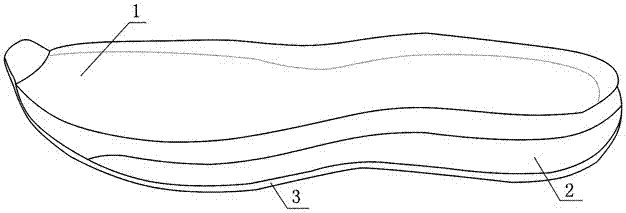

[0020] Embodiment one: if figure 1 As shown, a sports shoe sole of the present invention includes a support member 1 , a midsole 2 and an outsole 3 . The support part 1 is located above the midsole 2 and is made of hard EVA material. The midsole 2 is located at the heel between the support part 1 and the outsole 3 and extends to two-thirds of the sole of the foot. . The surface of the middle side wall of the sole is embossed with diamond grain particles of different sizes. The midsole of the shoe is made of a blended material containing olefin block copolymer and ethylene-vinyl acetate copolymer. There are two material formulations, one: the midsole material of the shoe contains olefin block copolymer, , talcum powder, zinc oxide, stearic acid, zinc stearate, polyethylene wax, titanium dioxide, foaming agent, crosslinking agent; the material ratio is: olefin block copolymer 75%, vinyl acetate copolymer 25% %, talc powder 8%, zinc oxide 1.5%, stearic acid 0.5%, zinc stearate...

Embodiment 2

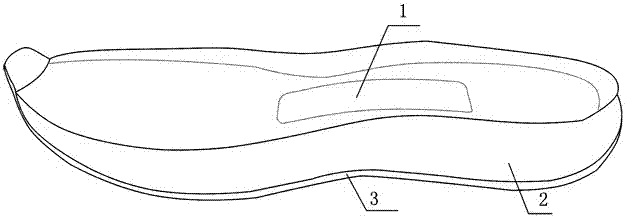

[0023] Embodiment two: if figure 2 As shown, on the basis of Embodiment 1, the shoe midsole 2 is applied to the sole of the foot, and the support member 1 is located at the middle waist of the shoe on the upper surface of the shoe midsole, increasing the area and thickness of the shoe midsole, and strengthening the height of the sole. Resilience performance. At the same time, the support part 1 at the middle waist of the shoe is made of nylon material with relatively high hardness. During the wearing process of the shoe, on the one hand, the rebound performance of the sole is enhanced to save the wearer's movement energy. , hard nylon support components, strengthen the support stability and anti-torsion effect of the sole.

[0024] On the basis of Embodiments 1 and 2, according to different design requirements, the midsole of the shoe can be set as a half-foot shape, which is only located at the heel. The embossing of the side wall of the midsole of the shoe can also be desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com