Stainless steel flux-cored wire and production method thereof

A technology of flux-cored welding wire and production method, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems of small pores in deposited metal, unreasonable composition configuration, poor weld formation, etc., and achieve evaporation The effect of reducing the amount, reducing the incidence of welding leaks, and improving moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

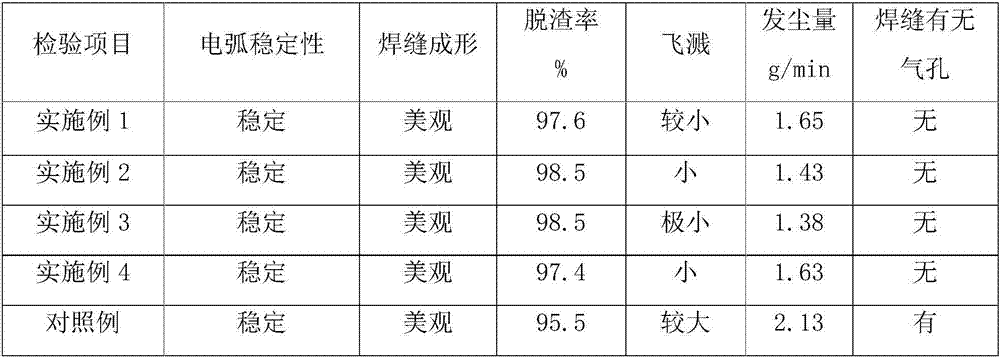

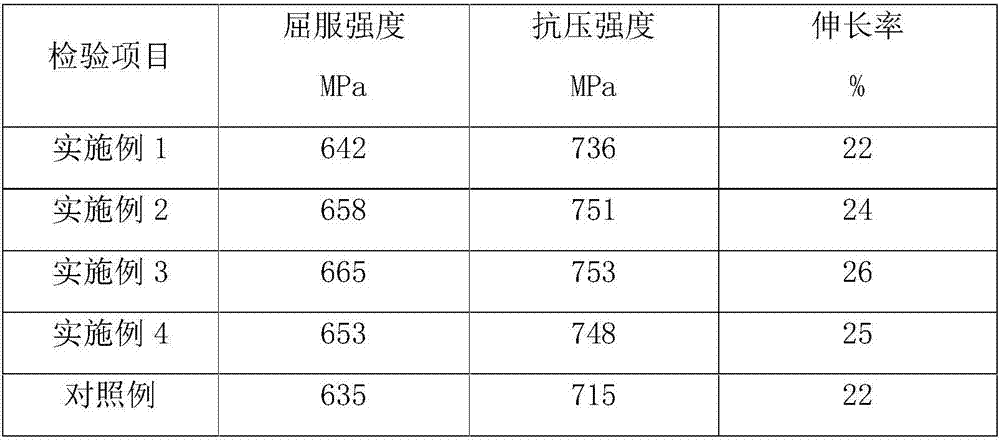

Examples

Embodiment 1

[0028] The stainless steel flux-cored wire is composed of a flux core and a stainless steel strip wrapped around the flux core. The flux core accounts for 28% of the total weight of the flux-cored wire. The flux core contains the following components in mass percentage: chromium powder 16%, rutile powder 12%, nickel 6% manganese powder, 5% manganese powder, 5% feldspar powder, 3% aluminum-magnesium alloy powder, 3% molybdenum iron powder, 3% composite nitride, 1% composite fluoride, 0.6% bismuth oxide, 0.5% tellurium dioxide, 0.5% of cerium oxide, the balance is iron powder, the sum of the mass percentages of the above components is 100%;

[0029] The stainless steel strip includes the following components in mass percentage: C: 0.025%, Cr: 18.5%, Ni: 9.5%, Mn: 0.80%, Al: 0.02%, Si≤0.04%, S≤0.005%, P≤0.01%, N≤0.003%, the balance is Fe and other unavoidable impurities.

[0030] The production method of stainless steel flux cored wire is:

[0031] S1. Weigh and mix rutile powd...

Embodiment 2

[0035] The stainless steel flux-cored wire is composed of a flux core and a stainless steel strip wrapped around the flux core. The flux core accounts for 25% of the total weight of the flux-cored wire. The flux core contains the following components in mass percentage: 15% chromium powder, 15% rutile powder, nickel 10% manganese powder, 8% manganese powder, 8% feldspar powder, 4% aluminum-magnesium alloy powder, 4% ferromolybdenum powder, 4% composite nitride, 2% composite fluoride, 1% bismuth oxide, 1% tellurium dioxide, 1% cerium oxide, the balance is iron powder, the sum of the mass percentages of the above components is 100%;

[0036] The stainless steel strip includes the following components in mass percentage: C: 0.03%, Cr: 19.0%, Ni: 10.0%, Mn: 0.82%, Al: 0.03%, Si≤0.04%, S≤0.005%, P≤0.01%, N≤0.003%, the balance is Fe and other unavoidable impurities.

[0037] The production method of stainless steel flux cored wire is:

[0038] S1. Weigh and mix rutile powder, feld...

Embodiment 3

[0042] The stainless steel flux cored wire is composed of a flux core and a stainless steel strip wrapped around the flux core. The flux core accounts for 23% of the total weight of the flux cored wire. The flux core contains the following components in mass percentage: chromium powder 18%, rutile powder 14%, nickel 8% manganese powder, 6% manganese powder, 7% feldspar powder, 3.2% aluminum-magnesium alloy powder, 3.5% molybdenum iron powder, 3.5% composite nitride, 1.5% composite fluoride, 0.8% bismuth oxide, 0.8% tellurium dioxide, 0.8% of cerium oxide, the balance is iron powder, the sum of the mass percentages of the above components is 100%;

[0043] The stainless steel strip includes the following components in mass percentage: C: 0.035%, Cr: 19.5%, Ni: 10.2%, Mn: 0.84%, Al: 0.032%, Si≤0.04%, S≤0.005%, P≤0.01%, N≤0.003%, the balance is Fe and other unavoidable impurities.

[0044] The production method of stainless steel flux cored wire is:

[0045] S1. Weigh and mix r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com